Absorption layer variable doped InGaAs avalanche photodiode and preparation method thereof

An avalanche photoelectric and absorbing layer technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of widening InGaAs avalanche photodiodes, achieve the effects of widening the working voltage range, improving detection efficiency, and reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

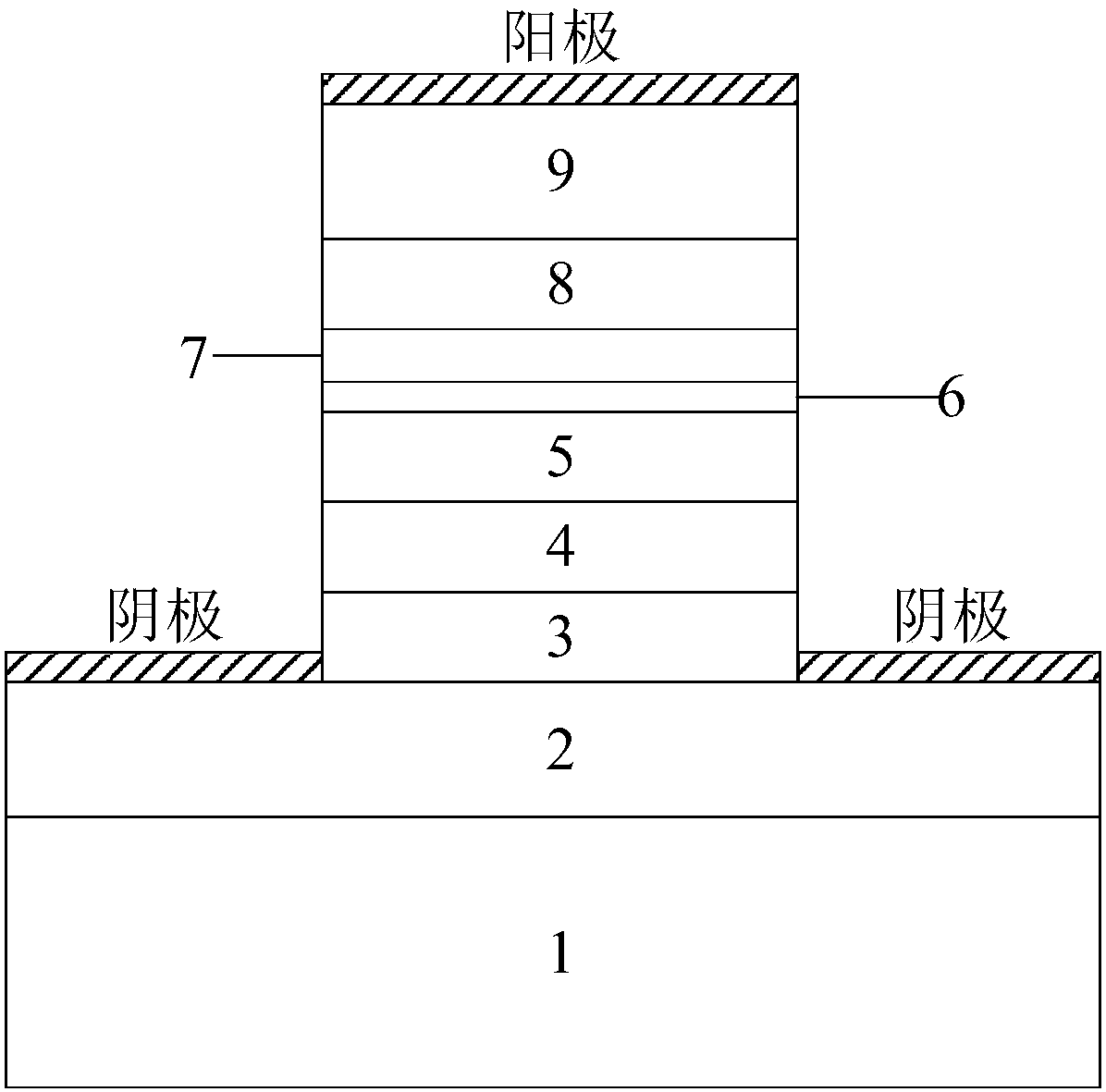

[0052] (1) Structural growth;

[0053] Using MOCVD (metal organic chemical vapor deposition) to epitaxially grow N-InP buffer layer 2 1 μm on N-type heavily doped InP substrate 1 sequentially, the doping concentration is 1×10 19 cm -3 ;N-In 0.53 Ga 0.47 The As absorption layer (3, 4 and 5) is 1.5 μm, and the doping concentration is 1×10 from bottom to top 17 cm -3 , 1×10 17 cm -3 , 1×10 17 cm -3 ;N-In (1-x) Ga x As y P (1-y) The composition gradient layer is 60.05 μm, and the doping concentration is 1×10 16 cm -3 ; N-InP charge layer 7 0.25μm, doping concentration is 1×10 17 cm -3 ; Intrinsically doped InP multiplication layer 8 0.5 μm; P-type heavily doped InP contact layer 9 2.5 μm, doping concentration is 1×10 19 cm -3 .

[0054] (2) deposited silicon dioxide (SiO 2 ) mask;

[0055] A layer of SiO with a thickness of 700 nm was deposited by plasma enhanced chemical vapor deposition (PECVD) 2 , as a mask for reactive ion etching (RIE).

[0056] (3) Phot...

Embodiment 2

[0063] (1) Structural growth;

[0064] Using MOCVD, the N-InP buffer layer 2 was epitaxially grown on the N-type heavily doped InP substrate 1 with a thickness of 1 μm, and the doping concentration was 1×10 19 cm -3 ;N-In 0.53 Ga 0.47 The As absorption layer (3, 4 and 5) is 1.5 μm, and the doping concentration is 2×10 from bottom to top 17 cm -3 , 1×10 17 cm -3 , 9×10 16 cm -3 ;N-In (1-x) Ga x As y P (1-y) Composition graded layer 6 0.05 μm, doping concentration 1×10 16 cm -3 ; N-InP charge layer 7 0.25μm, doping concentration is 1×10 17 cm -3 ; Intrinsically doped InP multiplication layer 8 0.5 μm; P-type heavily doped InP contact layer 9 2.5 μm, doping concentration is 1×10 19 cm -3 .

[0065] (2) Deposit SiO 2 mask;

[0066] Deposit a layer of SiO with a thickness of 700nm by PECVD technology 2 as a mask for RIE.

[0067] (3) Photolithographic pattern transfer;

[0068] The pattern on the photoresist plate is transferred to the photoresist through pro...

Embodiment 3

[0074] (1) Structural growth;

[0075] Using MOCVD, the N-InP buffer layer 2 was epitaxially grown on the N-type heavily doped InP substrate 1 with a thickness of 1 μm, and the doping concentration was 1×10 19 cm -3 ;N-In 0.53 Ga 0.47 The As absorption layer (3, 4 and 5) is 1.5 μm, and the doping concentration is 5×10 from bottom to top 17 cm -3 , 1×10 17 cm -3 , 5×10 16 cm -3 ;N-In (1-x) Ga x As y P (1-y) Composition graded layer 6 0.05 μm, doping concentration 1×10 16 cm -3 ; N-InP charge layer 7 0.25μm, doping concentration is 1×10 17 cm -3 ; Intrinsically doped InP multiplication layer 8 0.5 μm; P-type heavily doped InP contact layer 9 2.5 μm, doping concentration is 1×10 19 cm -3 .

[0076] (2) Deposit SiO 2 mask;

[0077] Deposit a layer of SiO with a thickness of 700nm by PECVD technology 2 as a mask for RIE.

[0078] (3) transfer of engraved graphics;

[0079] The pattern on the photoresist plate is transferred to the photoresist through process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com