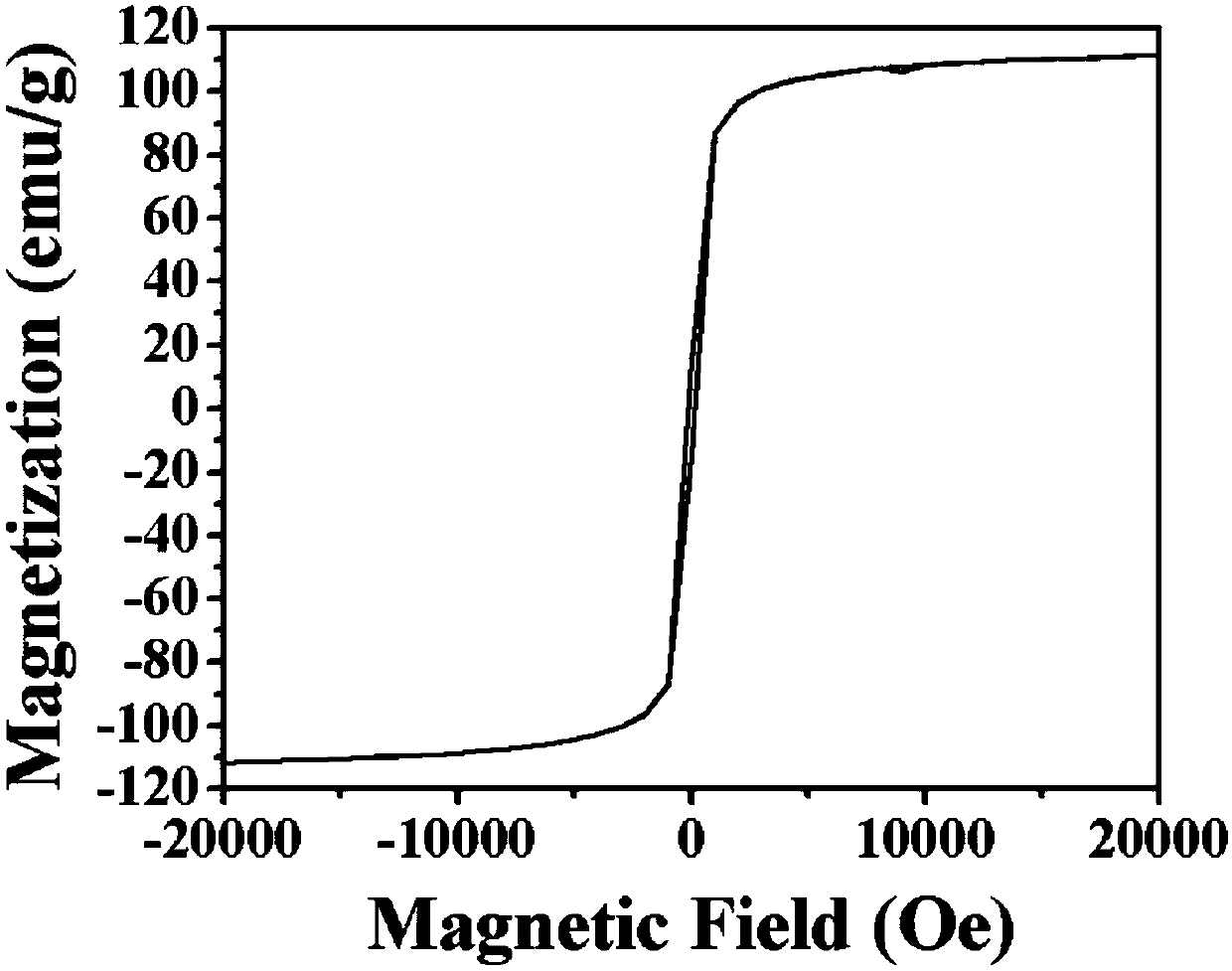

High-saturation-magnetization Fe3O4-Ag composite material and preparation method thereof

A composite material, magnetization technology, applied in the fields of inorganic material magnetism, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of reduced saturation magnetization of nanomaterials, limited magnetic properties, and inability to observe changes, etc. Achieve uniform particle size, increase purity and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

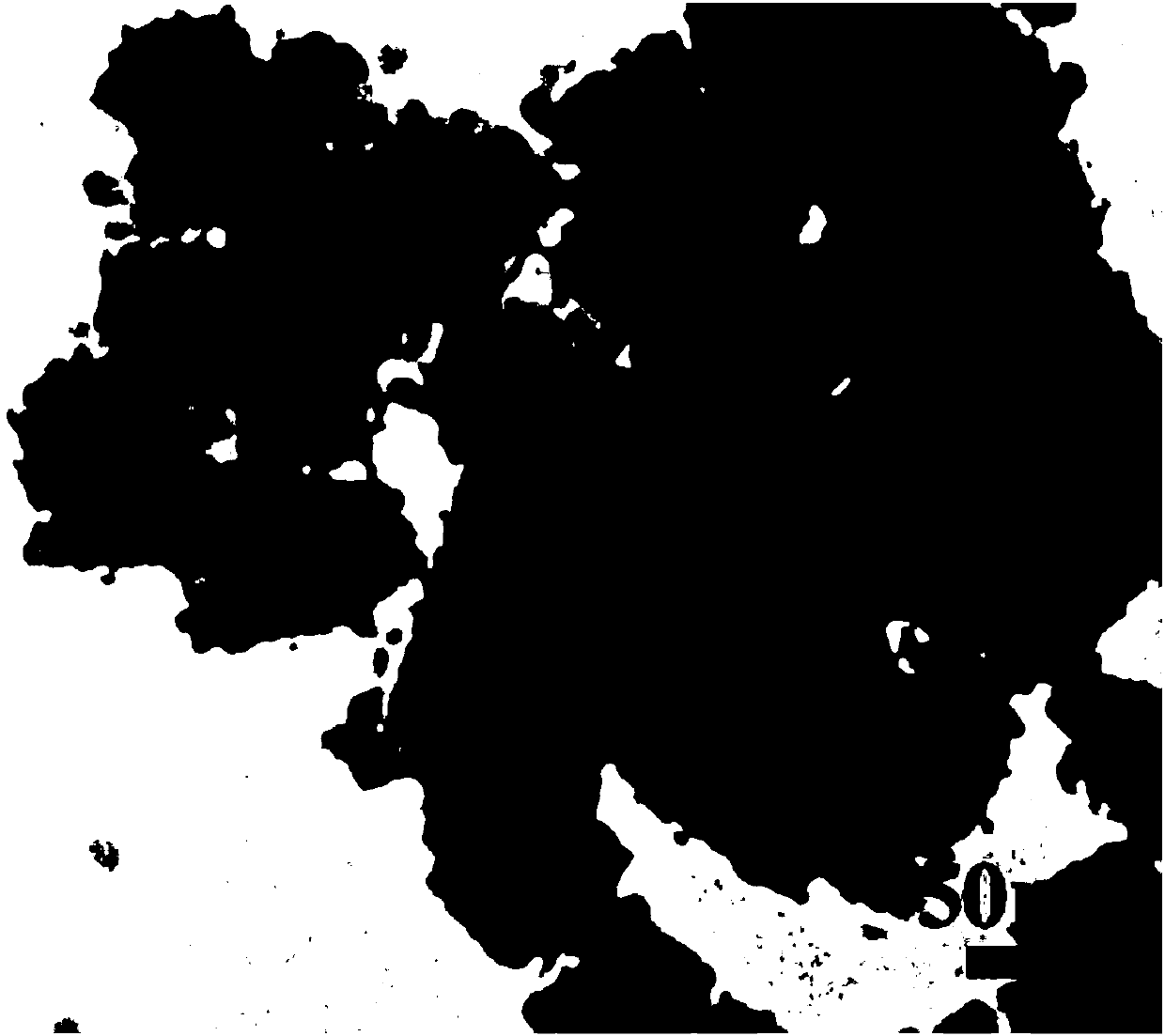

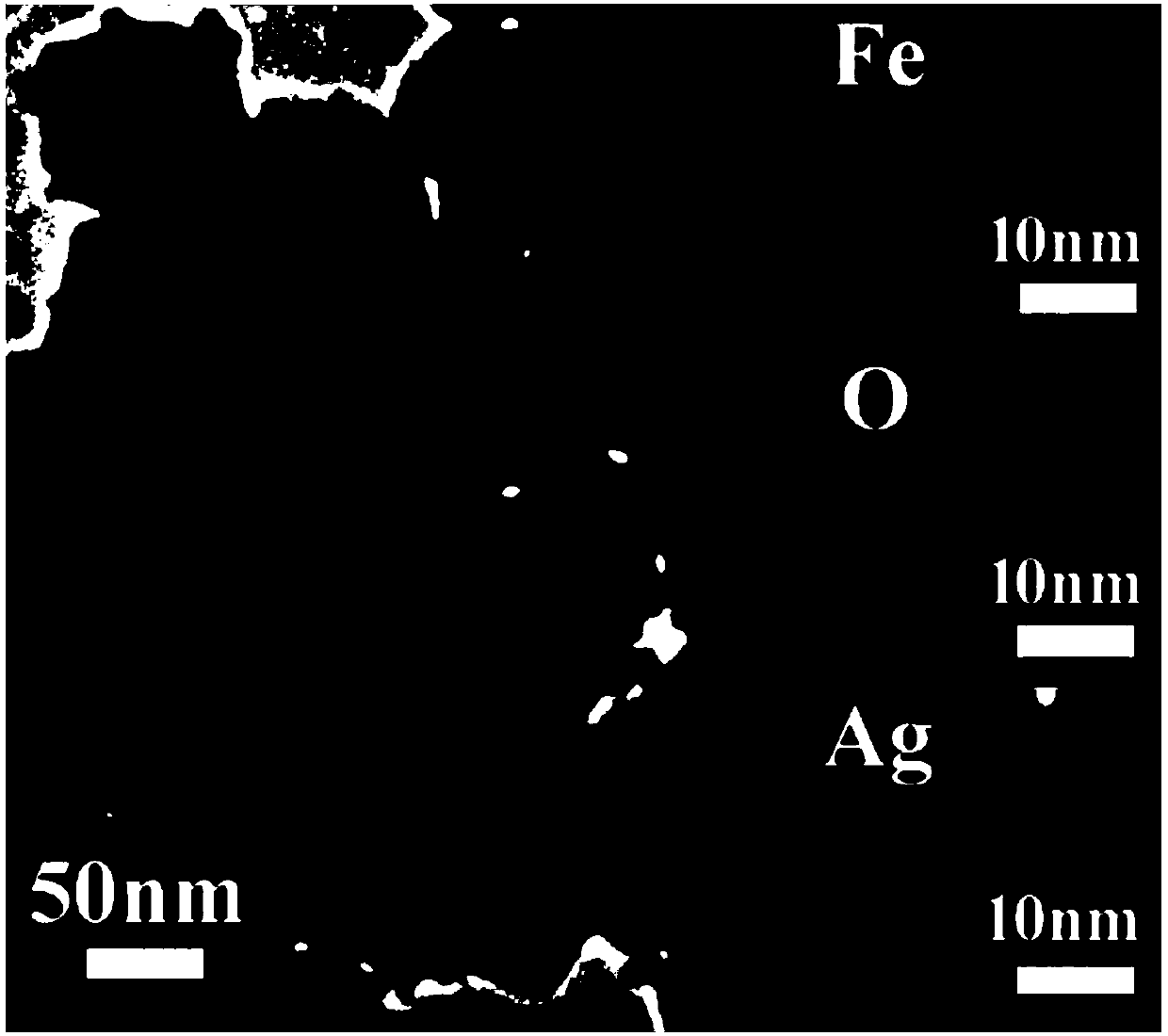

[0026] In this embodiment, a kind of Fe 3 o 4 -The preparation method of Ag composite material, comprises the steps:

[0027] S1. Using 0.7g iron acetylacetonate, 1.3mL oleic acid and 10mL benzyl ether as raw materials, in an argon atmosphere, heat up to 290°C, reflux for 8min, cool to room temperature, stand still to collect the precipitate, and use toluene and n-hexane to press any After washing with a mixed solvent of proportional composition, Fe 3 o 4 Nanoparticles, stored in chloroform; in which 10mgFe 3 o 4 After the nanoparticles were washed with methanol, they were added into 40 mL of methanol and mixed to obtain solution A.

[0028] S2. Mix 0.0009g of sodium borohydride and 0.046g of sodium citrate aqueous solution, heat and reflux at 60°C, stir for 30 minutes, slowly add 5mL of silver nitrate solution with a concentration of 0.001mol / L to the mixed solution, add hydroxide Adjust the pH value to 10.8 with sodium, continue heating for 20 minutes, and naturally co...

Embodiment 2

[0032] In this embodiment, a kind of Fe 3 o 4 -The preparation method of Ag composite material, comprises the steps:

[0033] S1. Using 0.72g iron acetylacetonate, 1.32mL oleic acid and 10.2mL benzyl ether as raw materials, in an argon atmosphere, heat up to 290°C, reflux for 8min, cool to room temperature, stand still to collect the precipitate, press toluene and n-hexane After washing with a mixed solvent of any proportion, Fe 3 o 4 Nanoparticles, stored in chloroform; in which 10.1mgFe 3 o 4 After the nanoparticles were washed with methanol, they were added into 39 mL of methanol and mixed to obtain solution A.

[0034] S2. Mix 0.00088g of sodium borohydride and 0.045g of sodium citrate aqueous solution, heat to reflux at 60°C, stir for 30min, slowly add 5.2mL of silver nitrate solution with a concentration of 0.001mol / L to the mixed solution, and add hydrogen Adjust the pH value to 10.8 with sodium oxide, continue heating for 20 minutes, and naturally cool to room te...

Embodiment 3

[0038] In this embodiment, a kind of Fe 3 o 4 -The preparation method of Ag composite material, comprises the steps:

[0039] S1. Using 0.74g iron acetylacetonate, 1.34mL oleic acid and 10.4mL benzyl ether as raw materials, in an argon atmosphere, heat up to 290°C, reflux for 8min, cool to room temperature, stand still to collect the precipitate, press toluene and n-hexane After washing with a mixed solvent of any proportion, Fe 3 o 4 Nanoparticles, stored in chloroform; in which 10.2mgFe 3 o 4 After the nanoparticles were washed with methanol, they were added into 38 mL of methanol and mixed to obtain solution A.

[0040] S2. Mix 0.00089g of sodium borohydride and 0.0465g of sodium citrate aqueous solution, heat to reflux at 60°C, stir for 30 minutes, slowly add 5.4mL of silver nitrate solution with a concentration of 0.001mol / L to the mixed solution, and add hydrogen Adjust the pH value to 10.8 with sodium oxide, continue heating for 20 minutes, and naturally cool to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com