Preparation method and application of a carbon dot/graphite-like phase carbon nitride composite photocatalyst

A technology of graphite phase carbon nitride and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. The left acupoint is seriously compounded and cannot effectively use sunlight, etc., to achieve the effect of high utilization rate of visible light, high degradation rate of organic matter and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A CDs / g-C of the present invention 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0028] (1) Preparation of carbon dots: Mix glucose solution and sodium hydroxide solution and sonicate for 0.5-5 hours, and take the mixed solution. Add hydrochloric acid (the concentration of hydrochloric acid is 0.01~1mol / L, pH=6~8), adjust the pH, add 50~300mL of dehydrated alcohol in the state of stirring, then add magnesium sulfate, magnesium sulfate (0.5wt%~30wt% ) is added in an amount of 1-50mg. After filtration, a clear solution is obtained by stirring and standing. The stirring time is 0.5-5h, and the standing time is 1-48h. Heating at 50-100°C, the solution changes color and solids are produced. The solid is ground to a powder. The concentration of the glucose solution is 0.1-5 mol / L, the concentration of the sodium hydroxide solution is 0.01-1 mol / L, and the molar ratio of the glucose solution and the sodium hydroxide solution is 1-2...

Embodiment 1

[0032] Preparation of carbon quantum dots

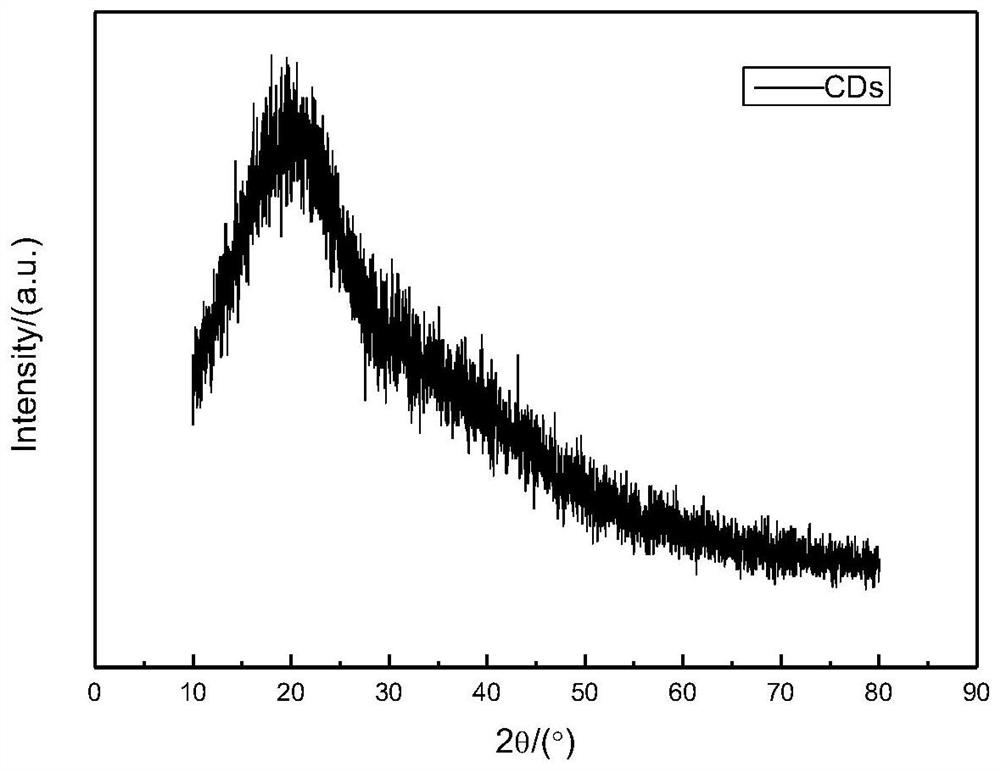

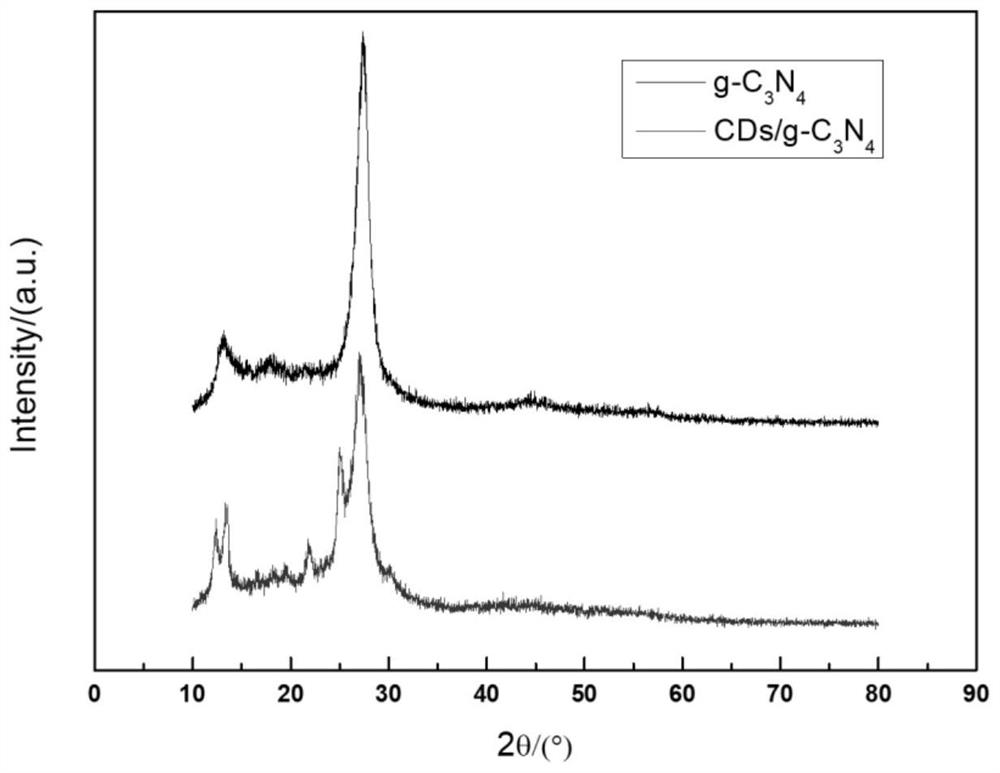

[0033] To prepare carbon quantum dots, take 100ml of 1mol / L glucose solution, add 50ml of 1mol / L sodium hydroxide solution, mix and sonicate for 1 to 5 hours, take 20mL of the mixed solution, add hydrochloric acid, adjust pH=7, and add 100mL of absolute ethanol, then add a certain amount of magnesium sulfate, stir for 20min, let stand for 24h, remove excess salt and water, filter to obtain a clear solution, heat at 100°C for 3-5h, the solution turns brown-black and solid carbon is produced . The solid is ground to a powder. From the XRD pattern ( figure 1 ), it can be seen that there is a visible diffraction peak around 2θ=20.7°, indicating that the carbon dots were successfully synthesized.

[0034] g-C 3 N 4 preparation of

[0035] Take a certain amount of melamine and place it in a porcelain crucible with a cover, then put it into a muffle furnace and raise the temperature to 500°C at a rate of 5°C / min, and keep it warm for ...

Embodiment 2

[0037] Preparation of carbon quantum dots

[0038]To prepare carbon quantum dots, take 10ml of 5mol / L glucose solution, add 300ml of 0.5mol / L sodium hydroxide solution, mix and sonicate for 1h, take 20mL of the mixed solution, add hydrochloric acid, adjust pH=6, add 100mL under stirring Then add a certain amount of magnesium sulfate, stir for 20min, let it stand for 24h, remove excess salt and water, filter to obtain a clear solution, heat at 50°C for 3-5h, the solution turns brown-black and solid carbon is produced. The solid is ground to a powder.

[0039] CDs / g-C 3 N 4 Preparation of Binary Compound Semiconductor Materials

[0040] CDs / g-C 3 N 4 Binary compound semiconductor materials are prepared by high-temperature solid-state method. Take a certain amount of prepared carbon dots and mix them with melamine, where CDs / g-C 3 N 4 The mass ratio of composite materials is 5:1 respectively. Grind with an agate mortar for 30 minutes. Then put it in a porcelain crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com