Alkyl-substituted naphthalene alkane preparation method and purpose of naphthalene alkane as jet fuel

A technology of decalin and alkyl, which is applied in the field of organic fuel application, can solve the problems of limited raw materials, high cost, and complicated process, and achieve the effects of low input cost, simple production equipment, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

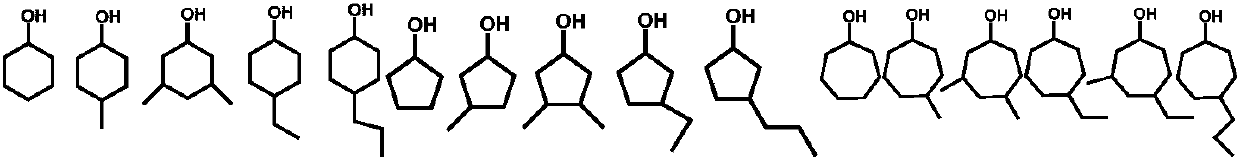

[0038] A kind of preparation method of decalin jet fuel containing substituent, it may further comprise the steps:

[0039] (1) Under the condition of 25℃, 50g of 98%H 2 SO 4 Add it into a three-necked flask, stir it mechanically, add 200g cyclohexanol dropwise within 30min, and continue the reaction for 30min;

[0040] (2) After the reaction is completed, the reaction mixture is separated, the organic phase is washed with 5wt% NaOH and water to neutrality, and finally anhydrous MgSO is added 4 After drying overnight, colorless organic fractions were obtained after separation.

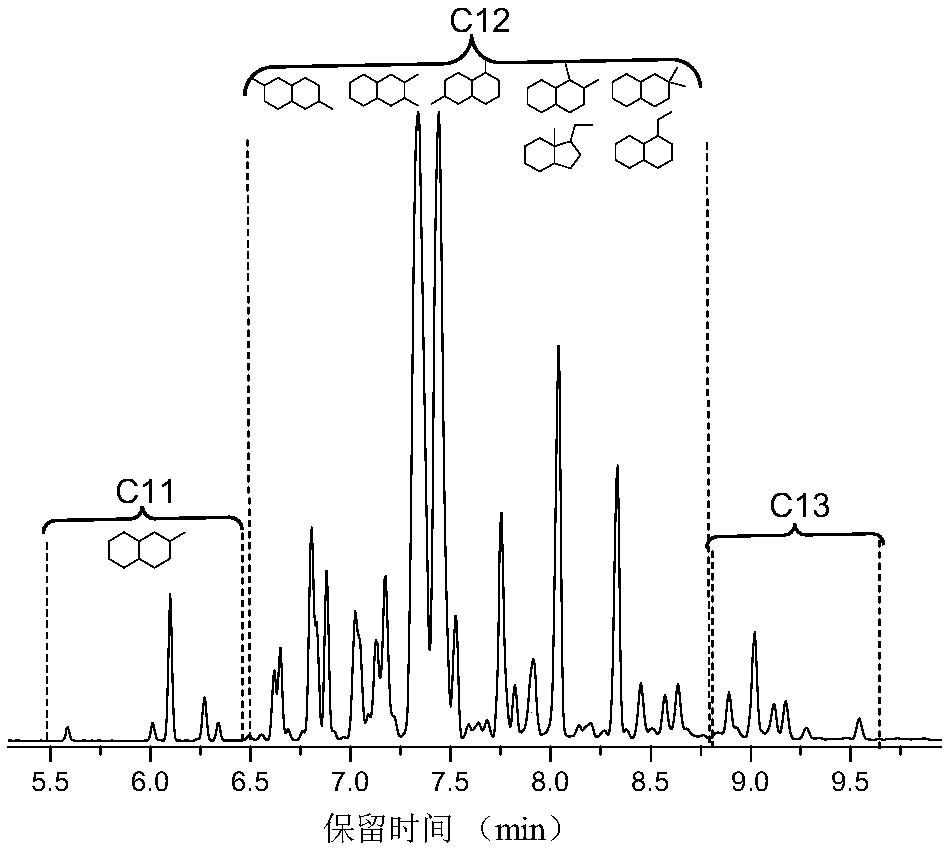

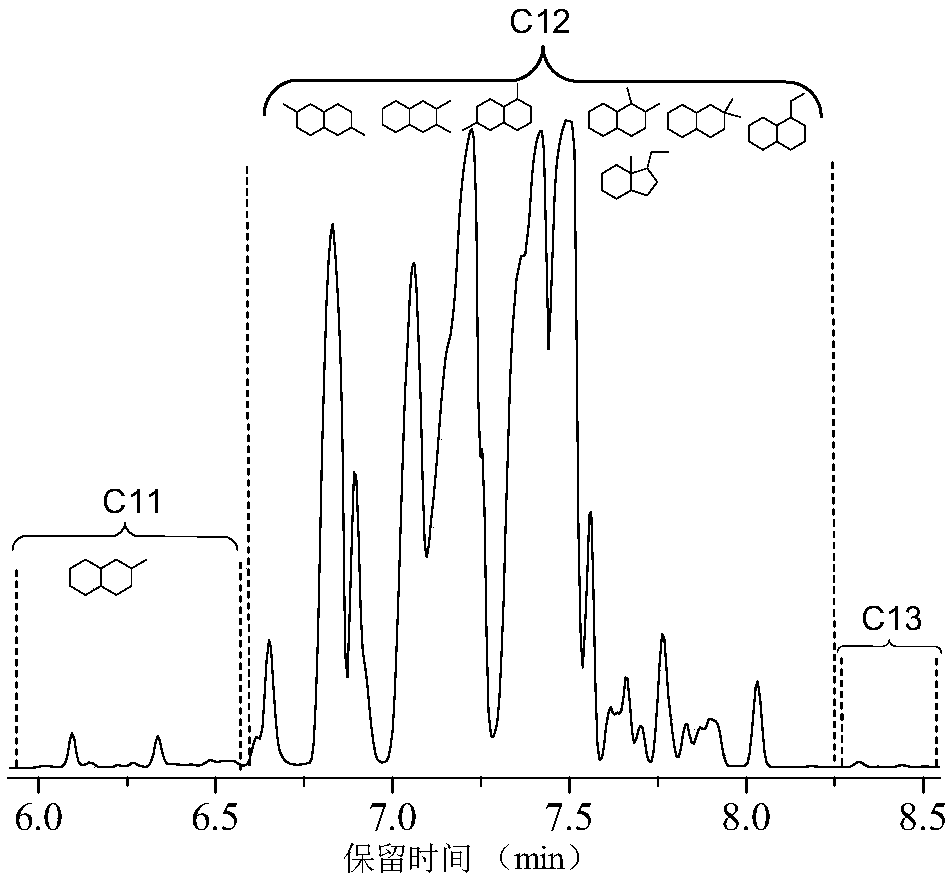

[0041] The prepared mixture was analyzed by gas chromatography-mass spectrometry (GC-MS), and the conversion rate of cyclohexanol was 100%, and the yield of decalin was 72%. The resulting mixture was distilled under reduced pressure to obtain an alkyl-substituted decalin mixture with a purity greater than 99%.

Embodiment 2-20

[0043] Embodiment 2-20 is the same as embodiment 1, with 95~98%H 2 SO 4 、HSO 3 F·SbF 5 、HSO 3 Liquid acids such as F and concentrated HCl and solid acids such as Nafion, Nafion-212, and HPW are used as catalysts to catalyze the alkylation reaction of cyclic alcohols, cyclic olefins, and cyclic ketones by themselves or between them.

[0044] Now the result of the yield of reactant and its consumption, catalyzer and its consumption, reactant conversion rate, temperature of reaction, reaction time and the decalin containing substituent is listed in table 1:

[0045] Table 1

[0046]

[0047]

[0048]

[0049] As can be seen from Examples 1-20, with 95-98% H 2 SO 4 、HSO 3 F·SbF 5 、HSO 3 F and concentrated HCl liquid acid and Nafion, Nafion-212 and HPW solid acid as catalysts can catalyze cyclic alcohols, cyclic olefins or cyclic ketones in the temperature range of -10 ° C to 120 ° C, or between themselves or each other reaction. And it can be seen from Table 1 th...

Embodiment 21

[0055] A kind of preparation method of decalin jet fuel containing substituent, it may further comprise the steps:

[0056] (1) Under the condition of 25℃, 60g of 98%H 2 SO 4 Add 170g of methylcyclopentane into a three-necked flask, mechanically stir for 5min, then add 200g of cyclohexanol dropwise within 60min, and react for 60min;

[0057] (2) After the reaction is completed, transfer the reaction mixture to a separatory funnel for extraction and separation. After washing the upper organic liquid twice with distilled water, wash twice with 5wt% NaOH, then wash twice with distilled water, and finally add anhydrous MgSO 4 After drying overnight, colorless organic fractions were obtained after separation.

[0058] The prepared mixture was analyzed by gas chromatography-mass spectrometry (GC-MS), and the conversion rate of cyclohexanol was 100%, the conversion rate of methylcyclopentane was 81%, and the yield of decalin was 88%. The resulting mixture is distilled under reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com