NV color center luminescence nano-diamond/tellurium germanate composite glass and preparation method thereof

A technology of nano-diamond and germanate telluride, which is applied in glass manufacturing equipment, diamond, glass forming, etc., can solve the problems of harming the body and the environment, occupying space, etc., and achieves low melting temperature, high uniformity, and transparent high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of tellurite glass;

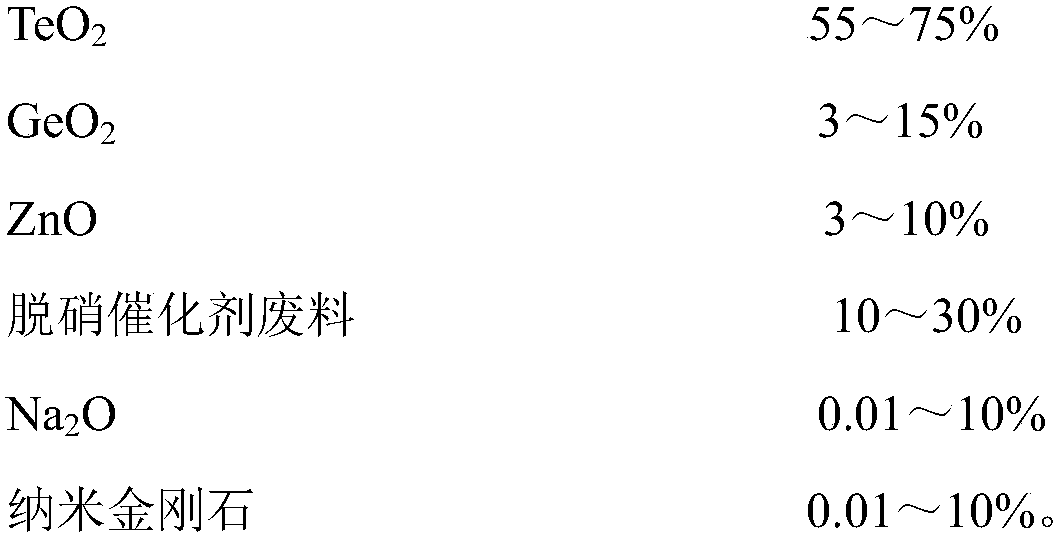

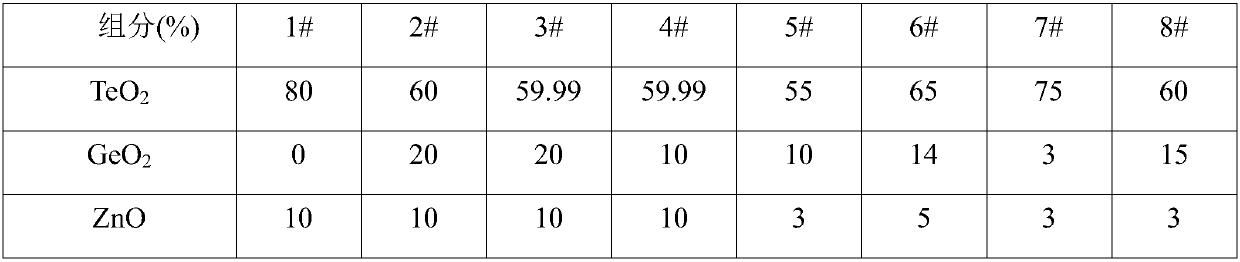

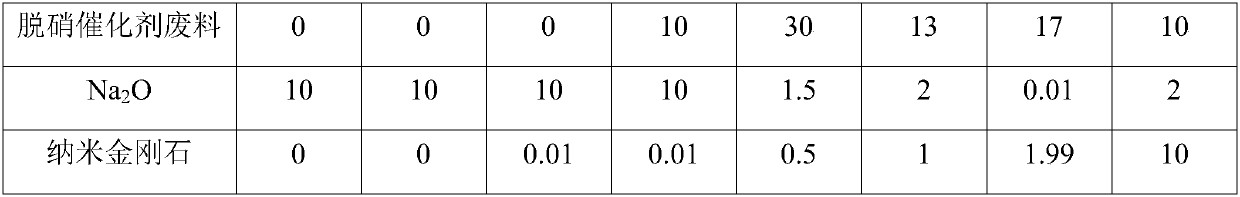

[0030] A kind of tellurate glass, raw material composition is as shown in 1# in table 1;

[0031] Concrete preparation process is as follows:

[0032] According to the mass percent of 1# glass composition in Table 1, calculate the corresponding weight of each composition, and take by weighing each raw material component;

[0033] Grind the raw materials evenly to form a mixture, put it into a gold crucible, and place it in a silicon carbide rod electric furnace at 800°C for 30 minutes to obtain molten glass, and then cool it down to 430°C at a rate of 11°C / hour; The molten glass is homogenized and clarified, and then quickly poured onto a mold that has been preheated to 370°C, and then placed in a muffle furnace that has been heated to 370°C. Cool down to 110°C at a rate of 1 hour, then close the muffle furnace, and cool down to room temperature.

[0034] The test results on the glass are as follows:

[0035] ① Process the ...

Embodiment 2

[0038] Embodiment 2: a kind of germanate tellurite glass;

[0039] A kind of germanate tellurite glass, the composition of raw materials is as shown in 2# in Table 1;

[0040] Concrete preparation process is as follows:

[0041] According to the mass percentage that 2# glass forms among the table 1, calculate the corresponding weight of each composition, and take each raw material component;

[0042] Grind the raw materials evenly to form a mixture, put it into a gold crucible, and put it in a silicon carbide rod electric furnace at 900 ° C for 30 minutes to obtain molten glass, and then quickly pour it into a mold that has been preheated to 450 ° C. Then put it into the muffle furnace that has been heated to 460°C, keep it warm for 3 hours, then cool it down to 110°C at a rate of 11°C / hour, then close the muffle furnace, and cool down to room temperature.

[0043] The test results on the glass are as follows:

[0044] ① The germanate tellurite composite glass prepared in thi...

Embodiment 3

[0047] Embodiment 3: a kind of nano-diamond / germanium tellurate composite glass;

[0048] A nano-diamond / germanate tellurite composite glass, the composition of raw materials is as shown in 3# in Table 1;

[0049] Concrete preparation process is as follows:

[0050] According to the mass percent that 3# glass forms among the table 1, calculate the corresponding weight of each composition, and take each raw material component;

[0051] Under the pumping of a 532nm semiconductor laser, the nano-diamond was tested, and the luminescence of the NV color center was not obtained at 500nm-800nm.

[0052] Vacuum-encapsulate the nano-diamond in a quartz test tube, put it into a high-temperature furnace that has been heated to 750°C, and keep flowing high-purity nitrogen gas during the heating process. After keeping the temperature for 2 hours, cool it down to 90°C at a rate of 150°C / hour. Then close the high-temperature furnace and cool down to room temperature;

[0053] Under the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com