Stone-like paint and preparation technology thereof

A technology of imitation stone coating and preparation process, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc. pollution and other problems, to achieve the effect of simple preparation process, suitable promotion and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

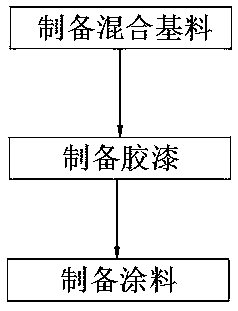

[0020] Embodiment 1: as figure 1 As shown, the present invention provides a stone-like coating, which is made of the following components by mass: 2 parts of nano-zinc oxide, 10 parts of silicon-acrylic emulsion, 8 parts of aluminum silicate, 4 parts of zeolite powder, and 0.1 part of titanium dioxide , 0.1 part of ethyl cellulose, 0.04 part of s-triazine, 6 parts of deionized water, 75 parts of natural colored sand, 10 parts of silicate solution, 3 parts of lignocellulose, 1 part of barium sulfate, 5 parts of sodium hexametaphosphate , 0.2 parts of ethylene glycol, 0.1 parts of curing agent, 1 part of thickener, 0.3 parts of film forming agent, 0.2 parts of defoamer, 0.2 parts of coupling agent, 0.3 parts of water repellent and 0.1 part of bactericidal preservative.

[0021] A kind of stone imitation coating preparation technology, comprises the steps:

[0022] 1) Preparation of mixed base material: Weigh the raw materials according to the above mass parts, mix zinc hydroxid...

Embodiment 2

[0030] Embodiment 2: as figure 1 As shown, the present invention provides a stone-like coating, which is made of the following components by mass: 3 parts of nano-zinc oxide, 12 parts of silicon-acrylic emulsion, 12 parts of aluminum silicate, 6 parts of zeolite powder, and 1 part of titanium dioxide , 0.3 parts of ethyl cellulose, 0.06 parts of s-triazine, 8 parts of deionized water, 86 parts of natural colored sand, 20 parts of silicate solution, 4 parts of lignocellulose, 3 parts of barium sulfate, 8 parts of sodium hexametaphosphate , 0.4 parts of ethylene glycol, 0.5 parts of curing agent, 3 parts of thickener, 0.5 parts of film forming agent, 0.3 parts of defoamer, 0.3 parts of coupling agent, 0.4 parts of water repellent and 0.2 parts of bactericidal preservative.

[0031] A kind of stone imitation coating preparation technology, comprises the steps:

[0032] 1) Preparation of mixed base material: Weigh the raw materials according to the above mass parts, mix zinc hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com