Polyvinylidene fluoride nano fibrous membrane and preparation method thereof

A polyvinylidene fluoride, nanofiber membrane technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problem of restricting the large-scale production of highly oriented zinc oxide nanomaterials, unable to form a film in one step, complicated operations, etc. problem, to achieve the effect of low cost, strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

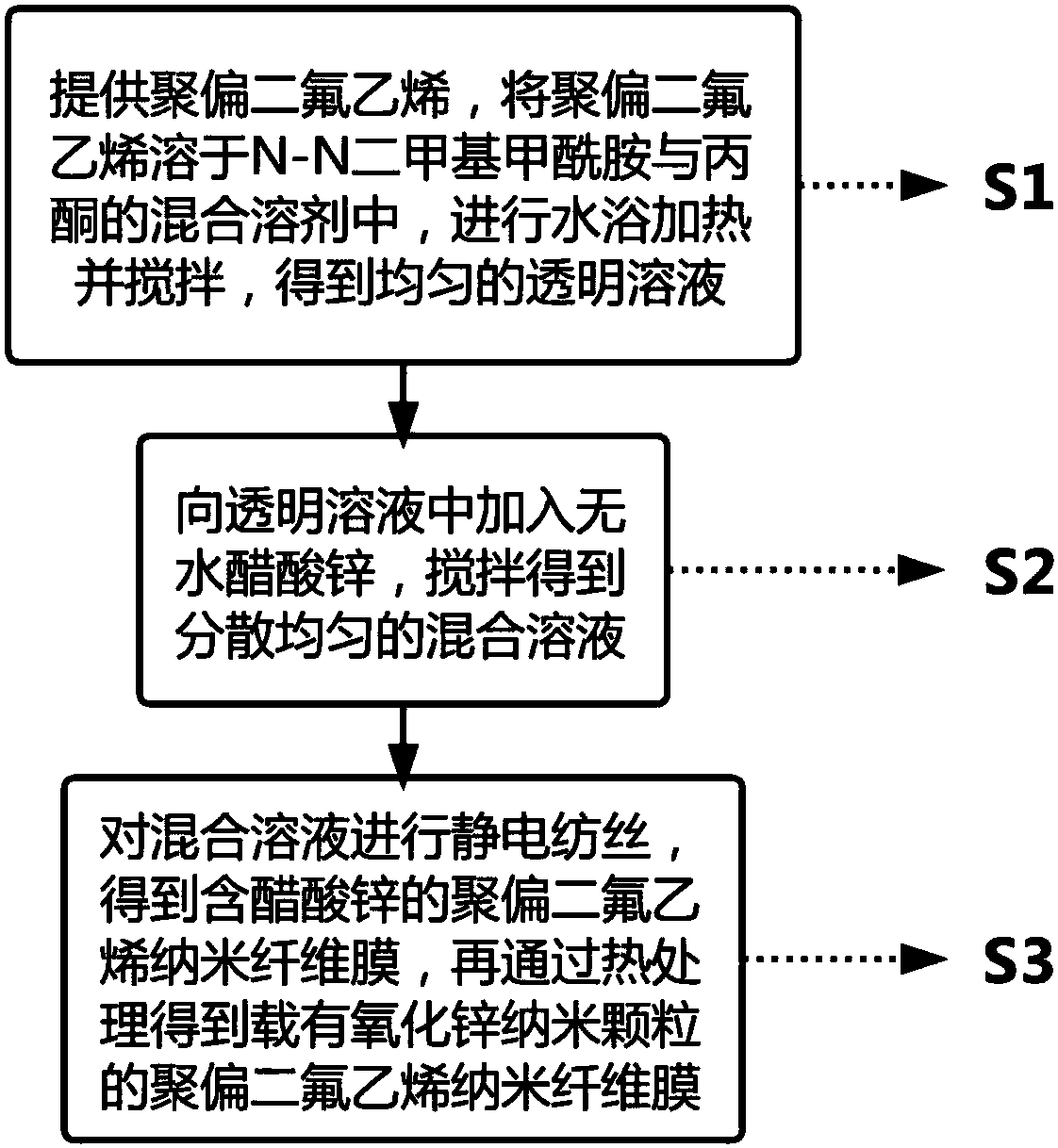

[0032] See figure 1 , the preparation method of polyvinylidene fluoride nanofiber film of the present invention comprises the following steps:

[0033] S1. Provide polyvinylidene fluoride, dissolve the polyvinylidene fluoride in a mixed solvent of N-N dimethylformamide and acetone, heat in a water bath and stir to obtain a uniform transparent solution;

[0034] S2. Add anhydrous zinc acetate to the transparent solution, and stir to obtain a uniformly dispersed mixed solution;

[0035] S3. Electrospinning the mixed solution to obtain a polyvinylidene fluoride nanofiber membrane containing zinc acetate, and then heat-treating to obtain a polyvinylidene fluoride nanofiber membrane loaded with zinc oxide nanoparticles.

[0036] In the preparation method, in order to facilitate the carrying out of the experimental reaction, the provided polyvinylidene fluoride is in granular form, and the anhydrous zinc acetate is in powder form. The mass ratio of N-N dimethylformamide to acetone...

Embodiment 1

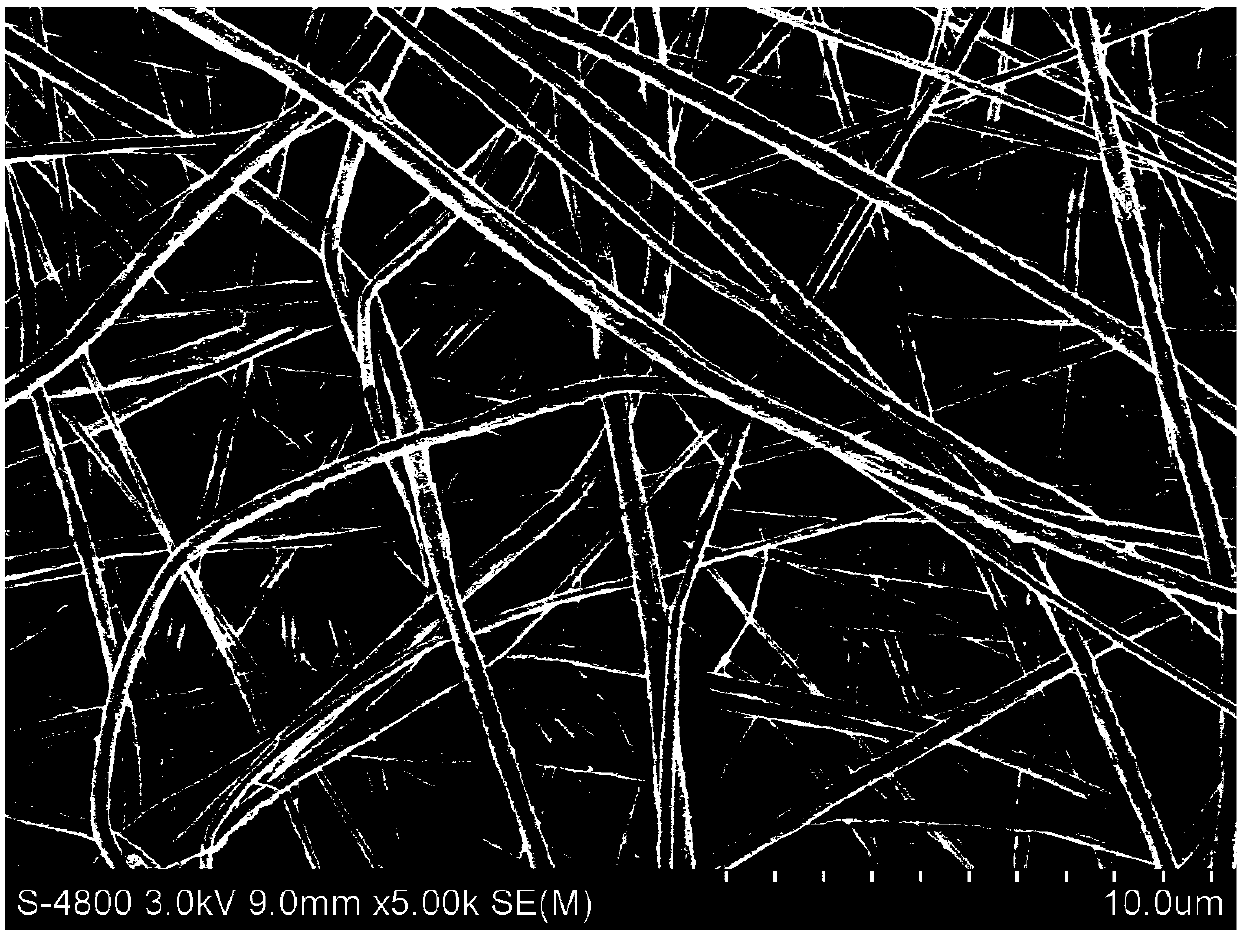

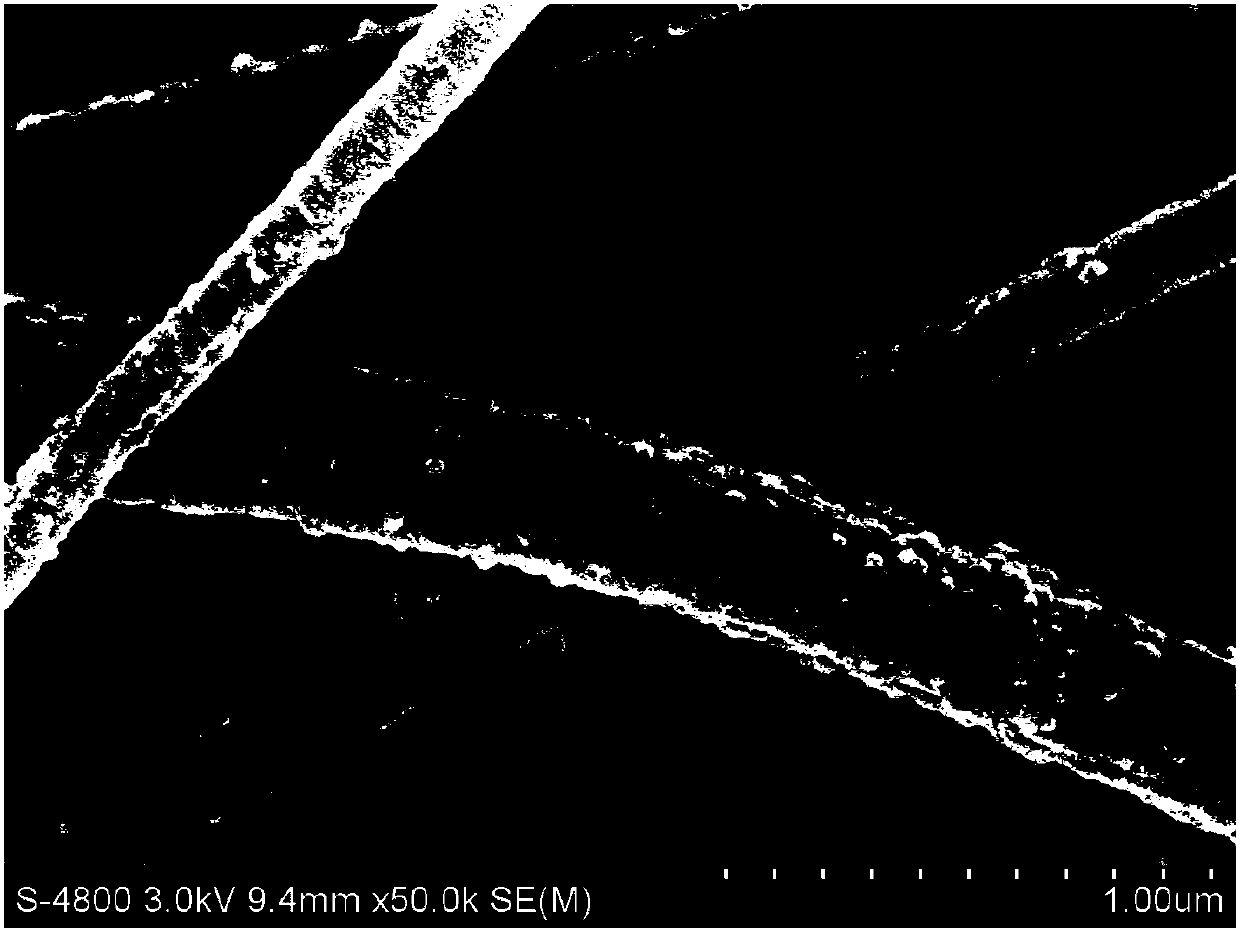

[0039] Take by weighing 31.5g N-N dimethylformamide (Dimethylformamide, DMF) and 23.5g acetone (mass ratio is 7:3), mix uniformly as solvent, then take by weighing 5g (polyvinylidene fluoride, PVDF) as solute, mix solute and solvent Place in a beaker, place the beaker in a heat-collecting magnetic heating stirrer for heating and stirring in a water bath, the temperature of the water bath is 55°C, indeed, in other embodiments, it can also be placed in other equipment for heating in a water bath. After the PVDF particles are completely dissolved to form a uniform transparent solution, a PVDF solution with a concentration of 10% is prepared. Subsequently, 1.5 g of anhydrous zinc acetate (Zn(Ac) was added to the above PVDF solution. 2 ) powder at room temperature and placed on a six-connected non-heating magnetic stirrer for stirring until a uniformly dispersed solution is formed. Of course, in other embodiments, it can also be placed on other equipment for stirring. Inject the s...

Embodiment 2

[0041] Weigh 31.5g DMF and 23.5g acetone, mix well as solvent, then weigh 5g PVDF particles as solute, put solute and solvent in a beaker, and place the beaker in a collector type magnetic heating stirrer for heating and stirring in a water bath , the temperature of the water bath is 55° C. It is true that in other embodiments, it can also be placed in other equipment for water bath heating. After the PVDF particles are completely dissolved to form a uniform transparent solution, a PVDF solution with a concentration of 10% is prepared. Subsequently, 1.5 g of anhydrous zinc acetate (Zn(Ac) was added to the above PVDF solution. 2) powder and placed on a six-connected non-heating magnetic stirrer for stirring (at room temperature) until a uniformly dispersed solution is formed. Of course, in other embodiments, it can also be placed on other equipment for stirring. The spinning liquid was injected into the liquid storage device for electrospinning, wherein the spinning voltage wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com