Bonding attenuation resistant EVA (Ethylene-Vinyl Acetate) packaging film for solar packaging material

A technology of solar energy encapsulation and encapsulation adhesive film, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of adhesive performance attenuation, accelerated destruction, etc., and achieve thermal expansion and contraction resistance Strong ability, long-term use, and high cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

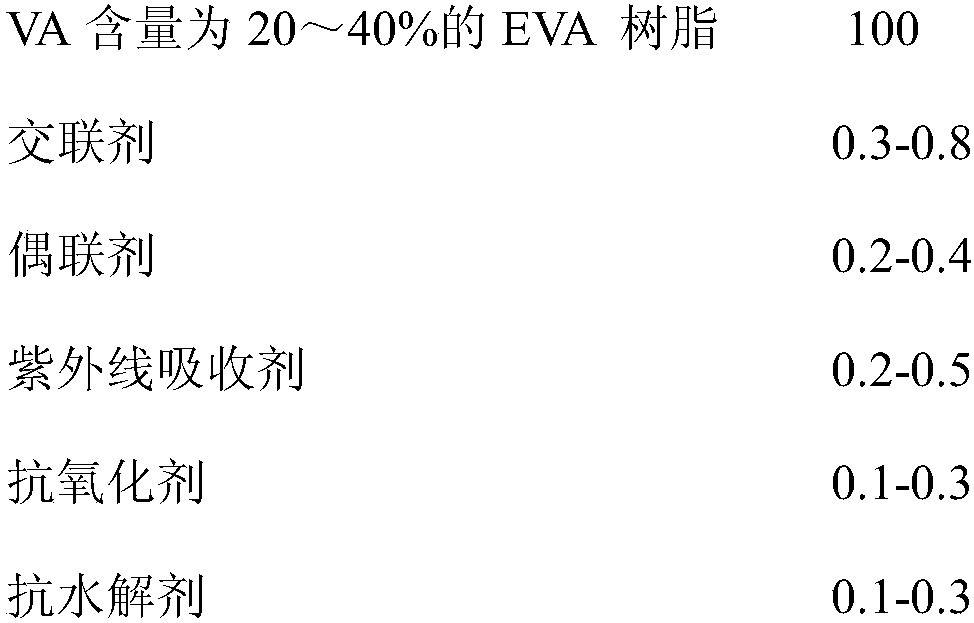

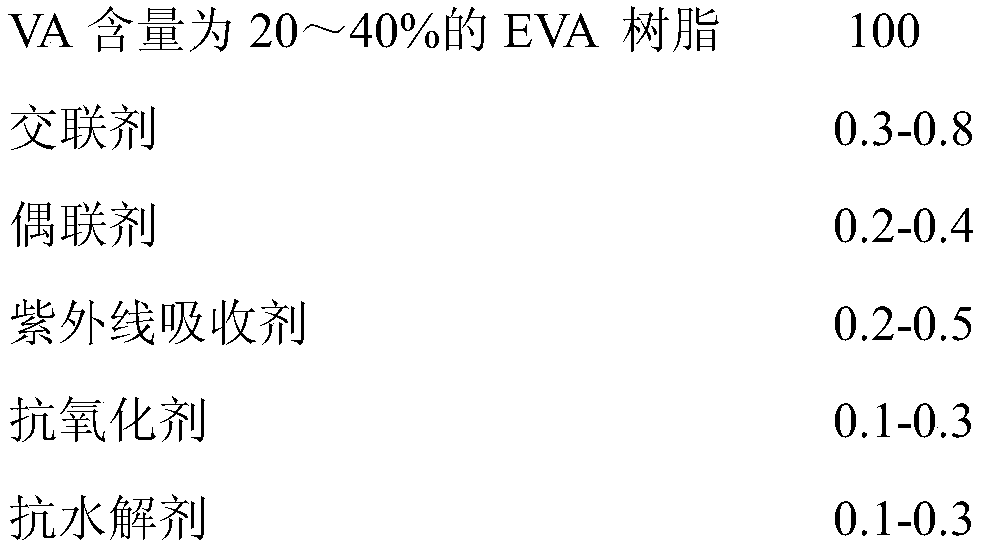

Method used

Image

Examples

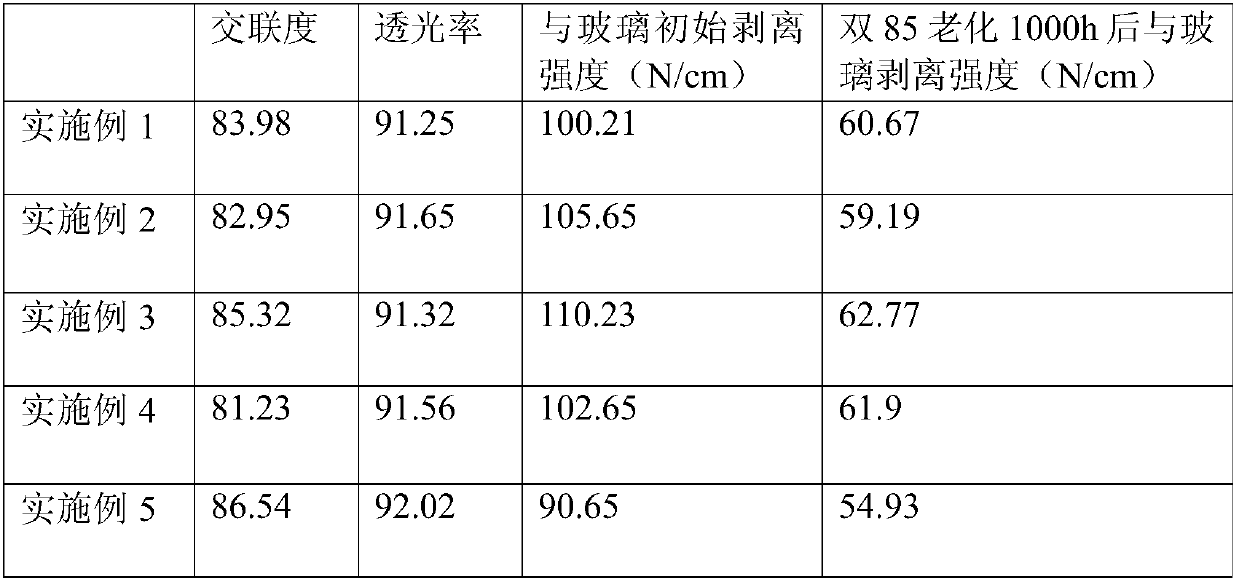

Embodiment 1

[0037] A solar cell encapsulation adhesive film, containing EVA, a crosslinking agent, an ultraviolet absorber, a coupling agent, an antioxidant, and an anti-hydrolysis agent; the crosslinking agent in the solar cell encapsulation adhesive film is 2,5-di-tert-butyl Peroxide-2,5-dimethylhexane, its quality is 0.5% of the EVA mass; the content of vinyl acetate in the EVA is 28%; the ultraviolet absorber is 2-hydroxyl-4-n-octyloxy Benzophenone, its quality is 0.2%% of EVA quality; Described antioxidant is three (2,4-di-tert-butylphenyl) phosphite, and its quality is 0.1% of EVA quality; Described coupling The agent is an addition reaction product of isocyanate propyltriethoxysilane, and its mass is 0.3% of the EVA mass; the anti-hydrolysis agent is carbodiimide, and its mass is 0.1% of the EVA mass. All kinds of additives are dissolved in xylene and then sprayed on the surface of EVA resin. After the EVA resin is mixed evenly by the mixer, it is put into the casting machine, and ...

Embodiment 2

[0044] A solar cell encapsulation adhesive film, containing EVA, a crosslinking agent, an ultraviolet absorber, a coupling agent, an antioxidant, and an anti-hydrolysis agent; the crosslinking agent in the solar cell encapsulation adhesive film is dicumyl peroxide, which The quality is 0.8% of the EVA quality; the content of vinyl acetate in the EVA is 32%; the ultraviolet absorber is 2-hydroxyl-4-n-octyloxybenzophenone, and its quality is 0.2% of the EVA quality ; The antioxidant is 3,5-di-t-butyl-4-hydroxyphenylpropionate octadecyl, and its quality is 0.1% of the EVA quality; the coupling agent is polymethylene polyphenylisocyanate trimethoxy The base silane addition reaction product has a mass of 0.4% of the EVA mass, and the anti-hydrolysis agent is carbodiimide, and its mass is 0.1% of the EVA mass. All kinds of additives are dissolved in xylene and sprayed on the surface of EVA resin. The EVA resin is mixed evenly by a mixer and put into a casting machine. After plastici...

Embodiment 3

[0051] A solar cell encapsulation adhesive film, containing EVA, a crosslinking agent, an ultraviolet absorber, a coupling agent, an antioxidant, and an anti-hydrolysis agent; the crosslinking agent in the solar cell encapsulation adhesive film is tert-butyl peroxide cumene , its quality is 0.5% of the EVA quality; the content of vinyl acetate in the EVA is 30%; the ultraviolet absorber is 2-hydroxyl-4-n-octyloxybenzophenone, its quality is 0.2% of the EVA quality %%; the antioxidant is three (2,4-di-tert-butylphenyl) phosphite, and its quality is 0.1% of the EVA quality; the coupling agent is 3-isocyanatopropyl trimethoxy The base silane addition reaction product, its quality is 0.4% of EVA quality; The anti-hydrolysis agent is carbodiimide, its quality is 0.2% of EVA quality. Dissolve various additives in dichloromethane and spray on the surface of the EVA resin. The EVA resin is mixed evenly by a mixer and then put into the casting machine. After plasticizing at 75°C, extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com