Method for cultivating chlorella by using food waste

A technology of catering waste and chlorella, which is applied in the field of cultivation of phytoplankton chlorella, can solve the problems of no chlorella technology or method announcement, and achieve the effect of resource utilization, labor cost saving and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

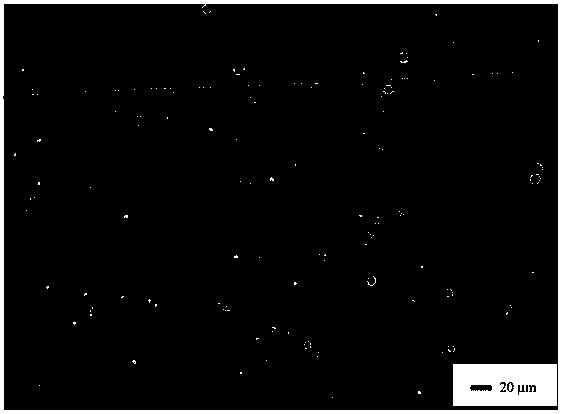

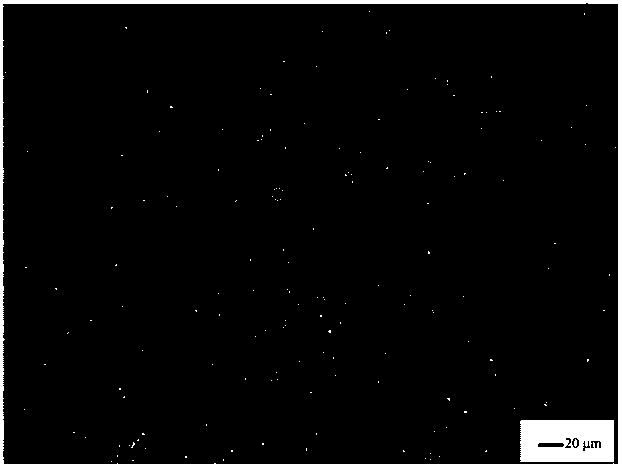

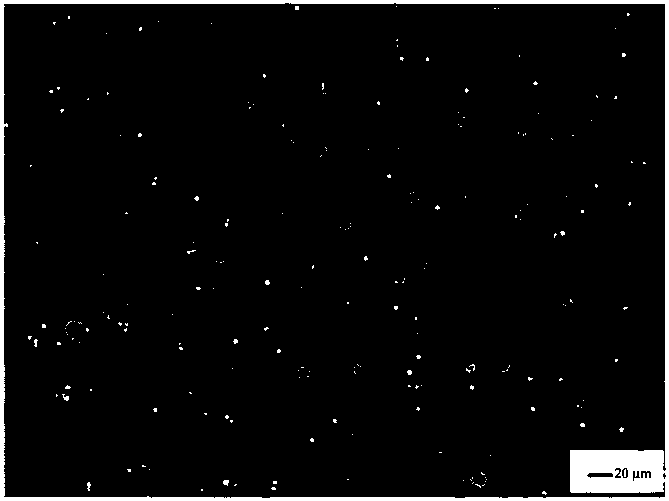

Image

Examples

Embodiment 1

[0034]In the warm month of May, obtain catering waste from restaurants, and remove non-food items such as paper towels, chopsticks, plastic bags, etc. to obtain 5.0kg of wet solid matter, and add it to an organic container with a height of 1m, a diameter of 40cm, and a hemispherical bottom. Into the glass column, inject tap water to a total volume of 100L. The plexiglass columns are placed in a glass greenhouse, and the room temperature in the glass greenhouse is 18-40°C in May. At the same time, add powdered calcium carbonate 50g, zeolite powder 25g, air-dried pond bottom mud powder 50g, calcium dihydrogen phosphate monohydrate 25g in this plexiglass column, and add commercially available Rhodopseudomonas mother liquor 0.1L, let The density of Rhodopseudomonas in food waste reaches 1×10 9 cell / L, and seal the column with aluminum foil. Then place an air stone with a length of 5 cm and a diameter of 3 cm at the bottom of the column for air aeration. The aeration can disturb ...

Embodiment 2

[0036] In the warm month of May, obtain catering waste from restaurants, and remove non-food items such as paper towels, chopsticks, plastic bags, etc. to obtain 5.0kg of wet solid matter, and add it to an organic container with a height of 1m, a diameter of 40cm, and a hemispherical bottom. Into the glass column, inject tap water to a total volume of 100L. The plexiglass columns are placed in a glass greenhouse, and the room temperature in the glass greenhouse is 18-40°C in May. At the same time, add powdered calcium carbonate 50g, zeolite powder 25g, air-dried pond bottom mud powder 50g, calcium dihydrogen phosphate monohydrate 25g in this plexiglass column, and add commercially available Rhodopseudomonas mother liquor 0.1L, let The density of Rhodopseudomonas in food waste reaches 1×10 9 cell / L, and seal the column with aluminum foil. Then place an air stone with a length of 5 cm and a diameter of 3 cm at the bottom of the column for aeration. The aeration can disturb the...

Embodiment 3

[0038] In the warm month of May, we obtained catering waste from restaurants, removed non-food items such as paper towels, chopsticks, and plastic bags, and obtained 20.0 kg of wet solid matter, which was added to an organic waste with a height of 1 m, a diameter of 40 cm, and a hemispherical bottom. Into the glass column, inject tap water to a total volume of 50L. The plexiglass columns are placed in a glass greenhouse, and the room temperature in the glass greenhouse is 18-40°C in May. At the same time, add powdered calcium carbonate 800g, zeolite powder 400g, air-dried pond bottom mud powder 1000g, calcium dihydrogen phosphate monohydrate 300g in this plexiglass column, and add commercially available Rhodopseudomonas mother liquor 10L, let catering The density of Rhodopseudomonas in garbage reaches 5×10 11 cell / L, and seal the column with aluminum foil. Then place two air stones with a length of 5 cm and a diameter of 3 cm at the bottom of the column for aeration. The aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com