Fermentation pineapple beverage thick slurry and preparation method thereof

A pineapple and thick syrup technology is applied in the directions of bacteria, sugar-containing food ingredients, and food ingredients used in food preparation as antioxidants, which can solve the problems of poor storage, easy browning of fermented pineapple beverage thick syrup, and the like. Pure taste, the effect of accelerated fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

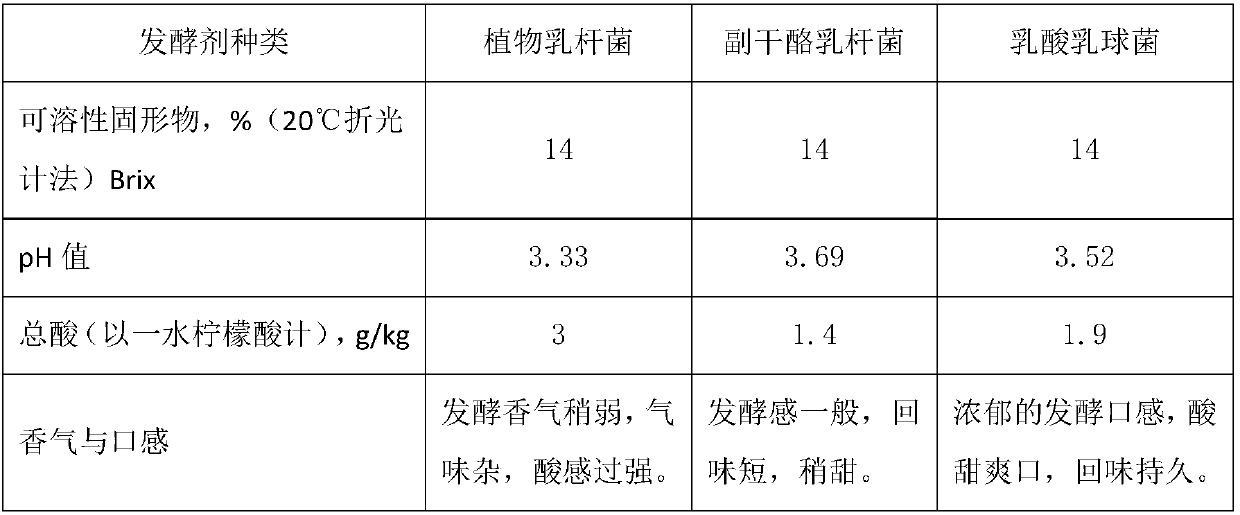

[0035] The making of embodiment 1 fermented pineapple juice (screening of starter)

[0036] Raw material dicing: use frozen pineapple with higher maturity as raw material (resolved the limitation of pineapple raw material by region and season), after slowing down, dicing is carried out by a dicing machine (particle size is 5 × 5 × 5).

[0037] Softening and beating: Put the diced pineapple into the sandwich pot, turn on the stirring and steam, boil for 10 minutes, and pass through the fine beater twice.

[0038] Enzymolysis and filtration: add 80ppm of pectinase to the pineapple pulp, enzymolysis at 50-55°C for 1 hour, and pass through a 200-mesh vibrating sieve to obtain pineapple juice.

[0039] Material preparation: Put 40g of pineapple juice, 10g of white sugar, and 50g of water into the fermenter, start stirring, and stir evenly.

[0040] Sterilization: Turn on the steam in the fermenter, heat the temperature of the material to 98-100°C, and keep it warm for 5 minutes. ...

Embodiment 2

[0048] The making of embodiment 2 fermented pineapple juice

[0049] Raw material dicing: use frozen pineapple with higher maturity as raw material (resolved the limitation of pineapple raw material by region and season), after slowing down, dicing is carried out by dicing machine (particle size is 5 × 5 × 5).

[0050] Softening and beating: Put the diced pineapple into the sandwich pot, turn on the stirring and steam, boil for 10 minutes, and pass through the fine beater twice.

[0051] Enzymolysis and filtration: add 80ppm of pectinase to the pineapple pulp, enzymolysis at 50-55°C for 1 hour, and pass through a 200-mesh vibrating sieve to obtain pineapple juice.

[0052] Material preparation: Put 40g of pineapple juice, 3g of glucose, 7g of white sugar, and 50g of water into the fermenter, start stirring, and stir evenly.

[0053] Sterilization: Turn on the steam in the fermenter, heat the temperature of the material to 98-100°C, and keep it warm for 5 minutes.

[0054] Co...

Embodiment 3

[0059] Embodiment 3 The making of fermented pineapple beverage thick slurry

[0060] 1. raw material pretreatment: fermented pineapple juice is prepared according to embodiment 2.

[0061] 2. Glue: Turn on the steam and stir, slowly add 0.15g sodium carboxymethyl cellulose (thickener) into the fructose syrup, and wait until the glue is fully dissolved.

[0062] 3. Material mixing: Put 30g of fermented pineapple juice, 7g of concentrated pineapple juice, 35g of white sugar and 8g of water into the material pot, turn on the steam and stir, when the temperature reaches 70°C, add the thickener, and wait until the colloid is completely mixed After homogeneous, add 0.9g citric acid and 0.3g malic acid, stir evenly.

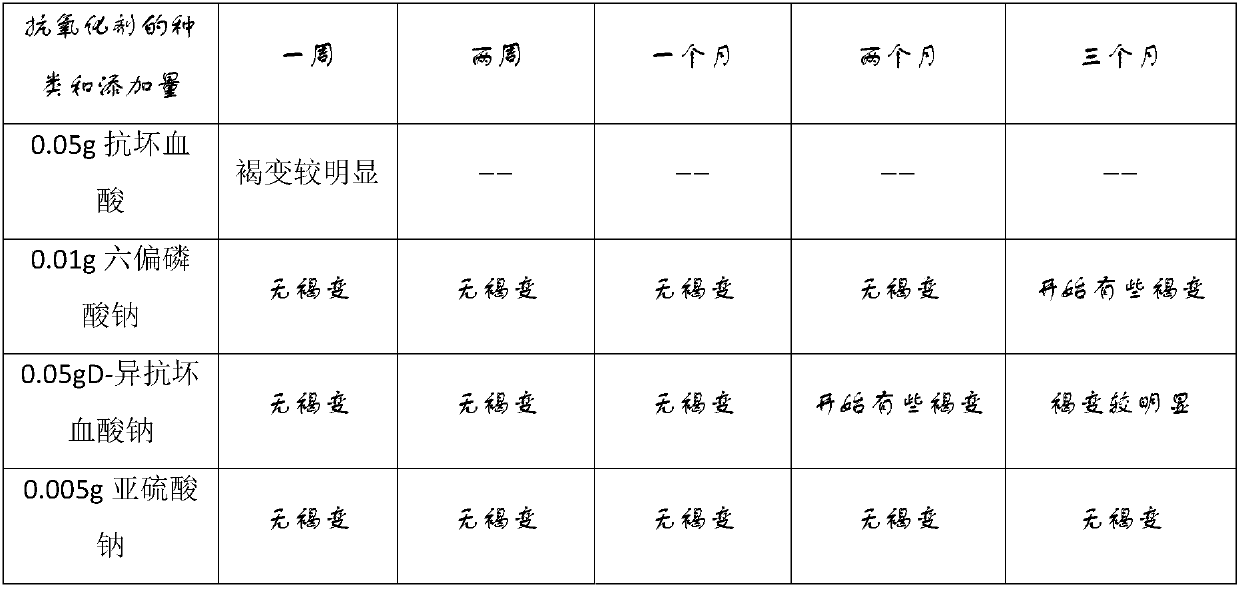

[0063] 4. Adjustment: When the temperature reaches 100°C, keep the temperature constant for 10 minutes. During this period, adjust the sensory and physical and chemical indicators to the specified range, add 0.001g tartrazine, 0.05g β-carotene, 0.045g potassium sorbate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com