Preparing method of anti-corrosion millipore filter membrane

A microporous membrane, corrosion-type technology, applied in the field of membrane separation material preparation, can solve the problems of complex composition, strong corrosion, affecting the normal use of the microfiltration system, etc., to enhance adhesion, improve corrosion resistance, good The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

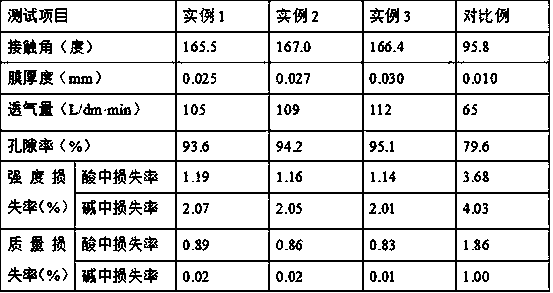

Examples

example 1

[0023] Measure 10mL of butyl acrylate, 6mL of methyl methacrylate and 10mL of deionized water, mix them in a beaker and stir for 4min, then add 4g of stearyl polyoxyethylene ether and 3g of azobisisobutyronitrile. Stir under protection for 14 minutes, and heat up to 45°C to obtain a self-made acrylic resin emulsion. Mix and stir the self-made acrylic resin emulsion and polytetrafluoroethylene dispersion emulsion in equal volumes for 6 minutes to obtain a self-made mixed emulsion. Weigh 6g sodium chromate, 3g Potassium chromate, 2g of cerium nitrate and 1g of sulfonated lignin were mixed in a beaker with 80mL of deionized water and stirred for 10min to obtain a self-made anti-corrosion mixture. The mass ratio of polyvinyl alcohol resin and mass fraction of 55% ethanol solution is mixed and placed in a reaction kettle, heated to 45°C and stirred for 20 minutes to obtain a mixed solution, and then added to the mixed solution are paraffin wax of 0.3 times the mass of the mixed solu...

example 2

[0025]Measure 15mL of butyl acrylate, 7mL of methyl methacrylate and 11mL of deionized water, mix them in a beaker and stir for 5min, then add 5g of stearyl polyoxyethylene ether and 4g of azobisisobutyronitrile, Stir under protection for 16 minutes, and heat up to 55°C to obtain a self-made acrylic resin emulsion. Mix and stir the self-made acrylic resin emulsion and polytetrafluoroethylene dispersion emulsion in equal volumes for 7 minutes to obtain a self-made mixed emulsion. Weigh 7g sodium chromate, 4g Potassium chromate, 3g of cerium nitrate and 2g of sulfonated lignin were mixed in a beaker with 90mL of deionized water and stirred for 11min to obtain a self-made anticorrosion mixture. The mass ratio of polyvinyl alcohol resin and mass fraction of 55% ethanol solution is mixed and placed in a reaction kettle, heated to 50°C and stirred for 25 minutes to obtain a mixed solution, and then added to the mixed solution are paraffin wax 0.3 times the mass of the mixed solution ...

example 3

[0027] Measure 20mL of butyl acrylate, 8mL of methyl methacrylate and 12mL of deionized water, mix them in a beaker and stir for 6min, then add 6g of stearyl polyoxyethylene ether and 5g of azobisisobutyronitrile. Stir under protection for 18 minutes, and heat up to 65°C to obtain a self-made acrylic resin emulsion. Mix and stir the self-made acrylic resin emulsion and polytetrafluoroethylene dispersion emulsion in equal volumes for 8 minutes to obtain a self-made mixed emulsion. Weigh 8g sodium chromate, 5g Potassium chromate, 4g of cerium nitrate and 3g of sulfonated lignin were mixed in a beaker with 100mL of deionized water and stirred for 12min to obtain a self-made anticorrosion mixture. The mass ratio of polyvinyl alcohol resin and mass fraction of 55% ethanol solution is mixed and placed in a reaction kettle, heated to 55°C and stirred for 30 minutes to obtain a mixed solution, then add paraffin wax with a mass of 0.3 times the mass of the mixed solution and polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com