Sodium persulfate production process

A kind of sodium persulfate, production process technology, applied in peroxyhydrate/peroxyacid, alkali metal sulfite/sulfite, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone It can solve the problems of high labor intensity, high unit consumption of raw materials and high production costs, and achieve the effect of reducing labor intensity, saving labor costs, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of production technology of sodium persulfate proposed by the present invention may further comprise the steps:

[0026] A. Add ammonium persulfate to the feeding kettle, add water and stir to dissolve, send it to filter A for filtration, then send it to the reaction deamination kettle, add liquid caustic soda and react under negative pressure to obtain sodium persulfate solution and ammonia gas A;

[0027] B. Carry out vacuum evaporation and crystallization of the sodium persulfate solution in the reaction deamination kettle to obtain the feed liquid, put the feed liquid into the middle tank, add liquid caustic soda to adjust the pH value of the system to 9, and then put it into the centrifuge A for centrifugal separation to obtain the wet material and mother liquor, the wet material is dried to obtain the sodium persulfate product;

[0028] C. The mother liquor obtained by centrifugation in B flows into the mother liquor collection tank, and then sent to the f...

Embodiment 2

[0031] A kind of production technology of sodium persulfate proposed by the present invention may further comprise the steps:

[0032] A. Add ammonium persulfate to the feeding kettle, add water and stir to dissolve, send it to filter A for filtration, then send it to the reaction deamination kettle, add liquid alkali dropwise and react under negative pressure to obtain sodium persulfate solution and ammonia Gas A; wherein, the weight ratio of ammonium persulfate to liquid caustic soda is 25:8; the pressure of the negative pressure is -0.01MPa;

[0033] B. Use saturated steam to vacuum evaporate and crystallize the sodium persulfate solution in the reaction deamination kettle to obtain the feed liquid, put the feed liquid in the middle tank, add liquid caustic soda to adjust the pH value of the system to 9, and then put it into centrifuge A for centrifugal separation Obtain the wet material and mother liquor, dry the wet material to obtain the sodium persulfate product;

[00...

Embodiment 3

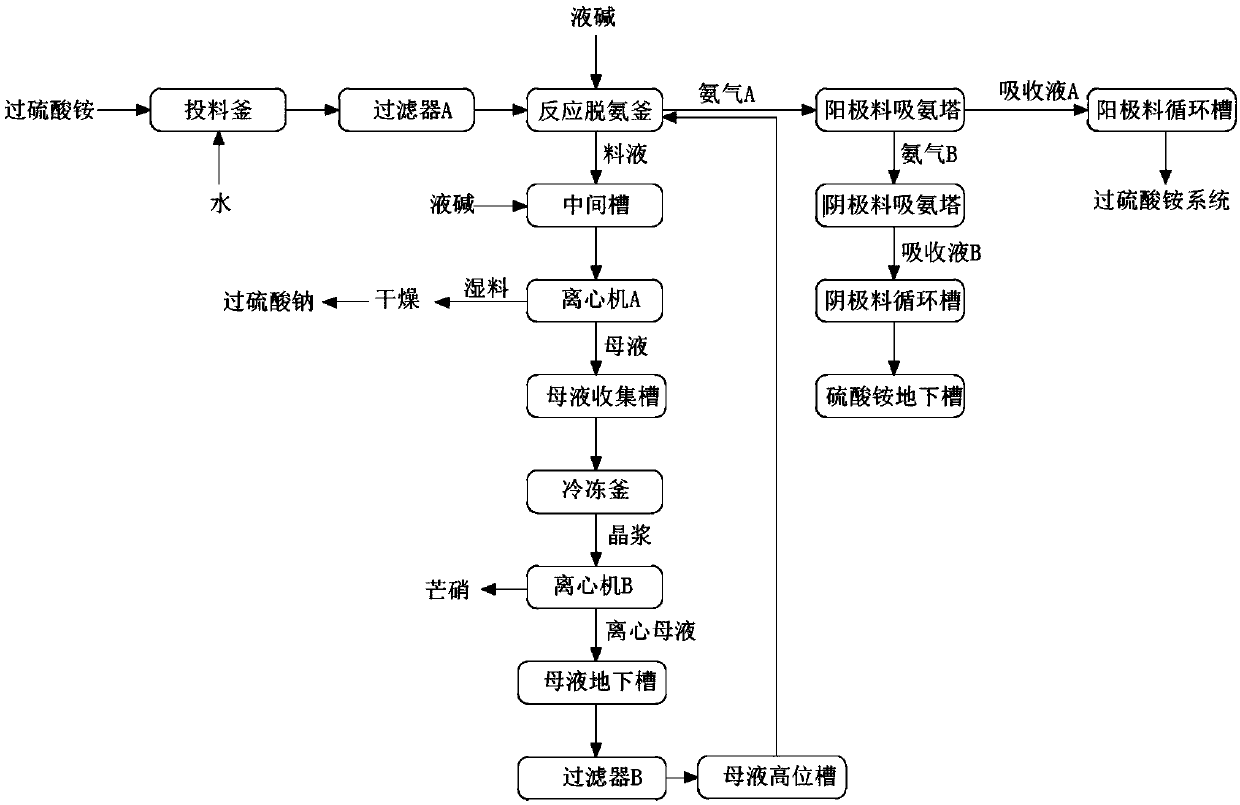

[0037] figure 1 For the flow chart of the production technology of the sodium persulfate that this embodiment proposes; With reference to figure 1 , the production technique of a kind of sodium persulfate that the present invention proposes, comprises the following steps:

[0038] A. Add ammonium persulfate to the feeding kettle, add water and stir to dissolve, send it to filter A for filtration, then send it to the reaction deamination kettle, add liquid alkali dropwise and react under negative pressure to obtain sodium persulfate solution and ammonia Gas A; wherein, the weight ratio of ammonium persulfate to liquid caustic soda is 15:15; the pressure of the negative pressure is -0.095MPa;

[0039] B. Use saturated steam to vacuum evaporate and crystallize the sodium persulfate solution in the reaction deamination kettle to obtain the feed liquid, put the feed liquid in the middle tank, add liquid caustic soda to adjust the pH value of the system to 10, and then put it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com