A method for preparing Ni-Ti-O Ni-rich nanopores on the surface of NiTi alloy

A ni-ti-o, nanopore technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of small diameter of Ni-Ti-O nanopore, low Ni content, large specific surface area, etc. , to achieve good long-term stability, high Ni content, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

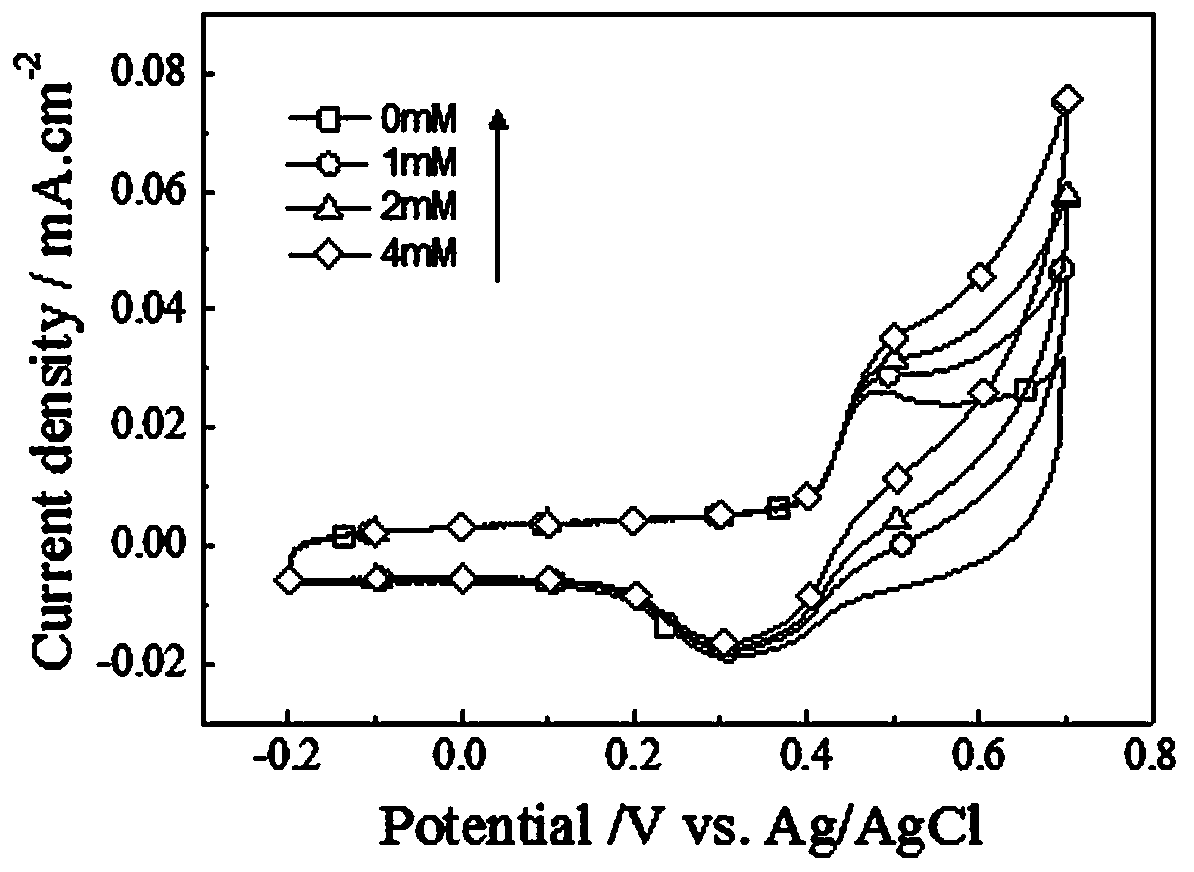

[0015] Embodiment 1: A method of preparing Ni-Ti-O rich Ni nanopores on the surface of NiTi alloy, the NiTi alloy specimen is pretreated by grinding and polishing, and then the pretreated NiTi alloy specimen is immersed in Na 2 CO 3 and H 2 In the ethylene glycol electrolyte of O, Ni-Ti-O Ni-rich nanopores were prepared on the surface by anodic oxidation method.

[0016] The specific preparation method is:

[0017] (1) Mechanically grind and polish the NiTi alloy specimen, then immerse it in acetone, absolute ethanol and deionized water for ultrasonic cleaning, and dry it with cold air to obtain the pretreated NiTi alloy specimen;

[0018] (2) With the pretreated NiTi alloy specimen as the anode and the platinum sheet as the cathode, in the presence of 0.5 wt% Na 2 CO 3 and 6.0vol% H 2 Anodic oxidation was carried out in the ethylene glycol electrolyte of O, the oxidation voltage was 15 V, the oxidation temperature was 20 ° C, and the oxidation time was 5 min, and Ni-Ti-O...

Embodiment 2

[0021] Embodiment 2: A kind of Ni-Ti-O Ni-rich nanopore method is prepared on the surface of NiTi alloy, NiTi alloy specimen is carried out grinding and polishing pretreatment, then the NiTi alloy specimen of pretreatment is immersed in Na 2 CO 3 and H 2 In the ethylene glycol electrolyte of O, Ni-Ti-O Ni-rich nanopores were prepared on the surface by anodic oxidation method.

[0022] The specific preparation method is:

[0023] (1) Mechanically grind and polish the NiTi alloy specimen, then immerse it in acetone, absolute ethanol and deionized water for ultrasonic cleaning, and dry it with cold air to obtain the pretreated NiTi alloy specimen;

[0024] (2) With the pretreated NiTi alloy specimen as the anode and the platinum sheet as the cathode, in the presence of 0.2 wt% Na 2 CO 3 and 5.5vol% H 2 O was anodized in ethylene glycol electrolyte, the oxidation voltage was 40 V, the oxidation temperature was 25 °C, and the oxidation time was 7 min. Ni-Ti-O nanopores were pr...

Embodiment 3

[0027] Embodiment 3: A kind of Ni-Ti-O Ni-rich nanopore method is prepared on the surface of NiTi alloy, NiTi alloy specimen is carried out grinding and polishing pretreatment, then the NiTi alloy specimen of pretreatment is immersed in containing Na 2 CO 3 and H 2 In the ethylene glycol electrolyte of O, Ni-Ti-O Ni-rich nanopores were prepared on the surface by anodic oxidation method.

[0028] The specific preparation method is:

[0029] (1) Mechanically grind and polish the NiTi alloy specimen, then immerse it in acetone, absolute ethanol and deionized water for ultrasonic cleaning, and dry it with cold air to obtain the pretreated NiTi alloy specimen;

[0030] (2) With the pretreated NiTi alloy specimen as the anode and the platinum sheet as the cathode, in the presence of 0.9 wt% Na 2 CO 3 and 5.0vol% H 2 O was anodized in ethylene glycol electrolyte, the oxidation voltage was 30 V, the oxidation temperature was 30 °C, and the oxidation time was 10 min, and Ni-Ti-O n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com