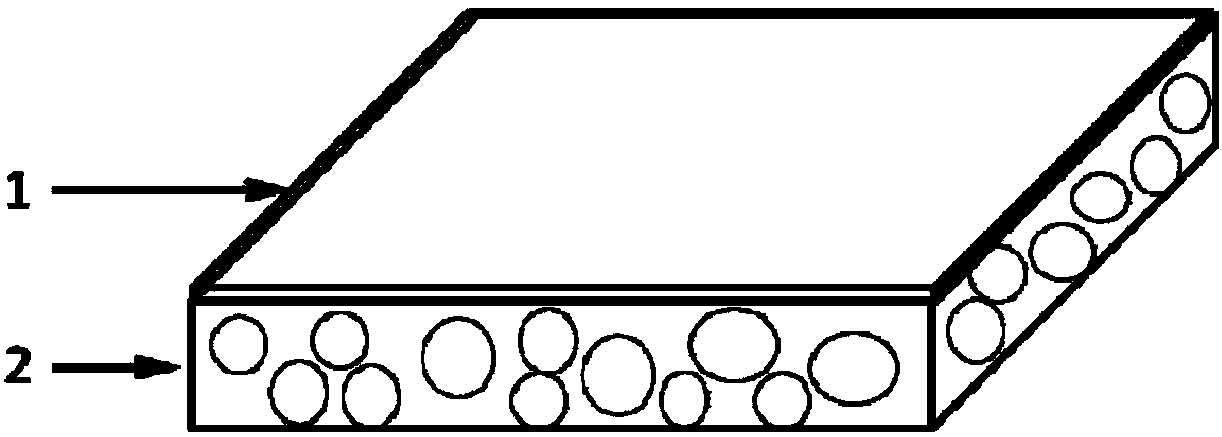

Biological cellulose skin repair material and preparation method thereof

A biological cellulose and skin repair technology, applied in the field of medical materials, can solve the problems of complex preparation process and difficult control of the structure of the material itself, achieve good biocompatibility, promote adhesion and proliferation speed, and the preparation method is simple and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of biocellulose skin repair material, the specific steps are as follows:

[0050] (1) prepare bacterial strain culture fluid;

[0051] The different components are mixed evenly to obtain the strain culture solution, wherein the content of glucose in the strain culture solution is 2wt%, the content of peptone is 0.3wt%, the content of yeast extract is 0.5wt%, and the content of citric acid is 0.05wt%. The content of disodium hydrogen phosphate is 0.02wt%, the content of potassium dihydrogen phosphate is 0.1wt%, and the balance is water;

[0052] (2) preparation of culture emulsion and bacterial liquid;

[0053] After carrying out homogeneous emulsification of 50 parts by weight of strain culture solution, 6 parts of peanut oil, 15 parts of polysorbate and 5 parts of gelatin, medical oxygen is passed into the emulsion at a speed of 0.1L / min, and maintained In 30 minutes, the culture emulsion with a pH value of 5 was obtained;

[0054] The refrigera...

Embodiment 2

[0062] A preparation method of biocellulose skin repair material, the specific steps are as follows:

[0063] (1) prepare bacterial strain culture fluid;

[0064] The different components are mixed evenly to obtain the strain culture solution, wherein the content of glucose in the strain culture solution is 3wt%, the content of peptone is 0.10wt%, the content of yeast extract is 0.05wt%, and the content of citric acid is 0.09wt%. The content of disodium hydrogen phosphate is 0.05wt%, the content of potassium dihydrogen phosphate is 0.01wt%, and the balance is water;

[0065] (2) preparation of culture emulsion and bacterial liquid;

[0066] After carrying out homogeneous emulsification of 52 parts by weight of strain culture solution, 5 parts of coconut oil, 3 parts of sucrose fatty acid ester and 22 parts of sodium alginate, medical air is passed into the emulsion at a speed of 1L / min , and maintained for 30 minutes to obtain a cultured emulsion with a pH value of 7;

[00...

Embodiment 3

[0075] A preparation method of biocellulose skin repair material, the specific steps are as follows:

[0076] (1) prepare bacterial strain culture fluid;

[0077] The different components are mixed evenly to obtain the strain culture solution, wherein the content of glucose in the strain culture solution is 4wt%, the content of peptone is 0.4wt%, the content of yeast extract is 0.15wt%, and the content of citric acid is 0.1wt%. The content of disodium hydrogen phosphate is 0.02wt%, the content of potassium dihydrogen phosphate is 0.08wt%, and the balance is water;

[0078] (2) preparation of culture emulsion and bacterial liquid;

[0079] After carrying out homogeneous emulsification of 56 parts by weight of strain culture solution, 9 parts of soybean oil, 5 parts of hydrogenated lecithin and 21 parts of chitosan, medical oxygen is passed into the emulsion at a speed of 0.2L / min , and maintained for 30 minutes to obtain a cultured emulsion with a pH value of 5;

[0080] Tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com