Industrialized preparation method of mesalazine

A technology of mesalazine and potassium hydroxide, applied in the field of industrialized preparation of mesalazine, can solve the problems of backward production technology, increase of synthesis cost, unfavorable large-scale production, etc., achieve optimized post-treatment mode, reduce environmental hazards, high The effect of industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

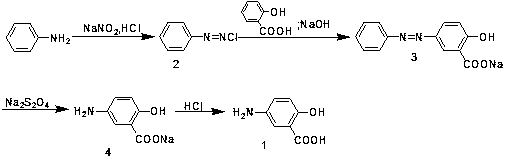

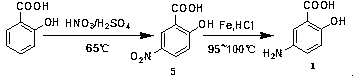

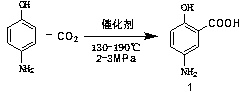

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of (II)

[0037]

[0038] Put 14 kg (250 mol) of potassium hydroxide into a 100 L reactor, add 50 L of water to fully dissolve it, keep the temperature at 20-40°C, and slowly add 10 kg (49.6 mol) of 2-chloro-5-nitrate Benzoic acid (I), warming up to 120-140 ° C, reacted at this temperature for 6 hours, TLC followed the reaction process, until the raw materials were completely reacted, cooled to room temperature, and the pH of the reaction system was adjusted between 1-3 with 17L hydrochloric acid , continue to stir for 1.5 hours, filter, wash the filter cake with 50L water, beat the filter cake with 30L water at 30°C, filter, continue to wash the filter cake with 50L water, and dry at 65°C for 12 hours to obtain 2-hydroxy-5-nitrate 8.81 kg of benzoic acid (intermediate II), yield: 97%, purity: 99.88%.

[0039] (2) Preparation of crude product of mesalamine (1)

[0040]

[0041] Put 3.26kg (30.6mol) of sodium carbonate into a 100 L reactor, add 64...

Embodiment 2

[0045] (1) Preparation of (II)

[0046]

[0047] Put 50g (0.893mol) of sodium hydroxide into a 500 mL reactor, add 179 mL of water to fully dissolve it, keep the temperature at 20-40°C, and slowly add 35.7g (0.177mol) of 2-chloro-5-nitro Benzoic acid (I), heated up to 120-140°C, reacted at this temperature for 6 hours, followed the reaction process by TLC, after the raw materials were completely reacted, cooled to room temperature, and adjusted the pH of the reaction system between 1-3 with 60.7mL hydrochloric acid , continue to stir for 1.5 hours, filter, wash the filter cake with 179 mL of water, beat the filter cake with 107 mL of water at 30 ° C, filter, continue to wash the filter cake with 179 mL of water, and dry at 65 ° C for 12 hours to obtain 2-hydroxy-5-nitrate 31.11 g of benzoic acid (intermediate II), yield: 96%, purity: 99.78%.

[0048] (2) Preparation of crude product of mesalamine (1)

[0049]

[0050] Put 11.6g (0.109mol) of sodium carbonate into a 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com