N-trimethyl chitosan microsphere, preparation method thereof and application of microsphere in reduction of dielectric loss of vegetable oil

A technology of trimethyl chitosan microspheres and trimethyl chitosan, which is applied in its preparation and application in reducing the dielectric loss of vegetable oil, in the field of N-trimethyl chitosan microspheres, can solve the problem of reducing chelation , electric neutralization and adsorption bridging, difficult separation of adsorbent and oil, reducing oil contact area, etc., to achieve the effect of reducing the dielectric loss of vegetable oil, easy operation, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

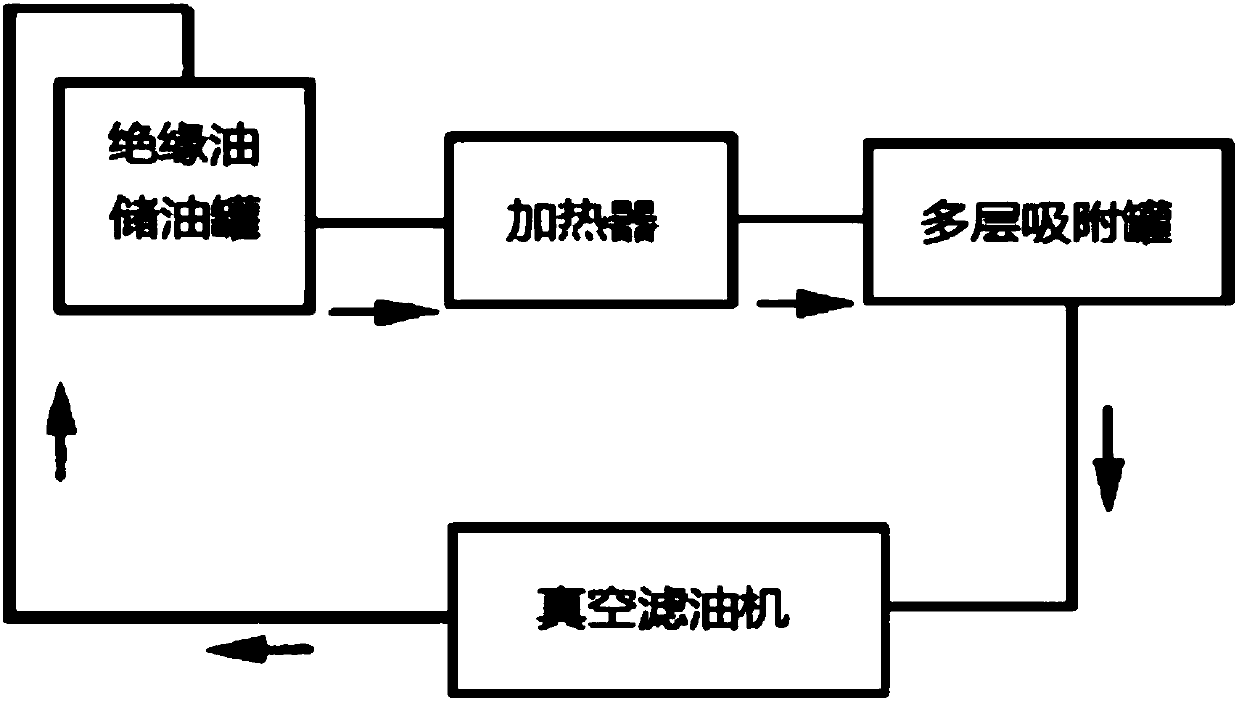

Method used

Image

Examples

preparation example Construction

[0033] The present embodiment provides a kind of preparation method of N-trimethyl chitosan microsphere, comprises the following steps:

[0034] S1. Mix chitosan, sodium iodide and N-methyl-2-pyrrolidone with a viscosity of 0.25 to 0.65 Pa·s and react in the dark to obtain a reaction solution, and add the first sodium hydroxide solution and iodine to the reaction solution Methane is reacted in the dark to obtain a solution, and then the solution is precipitated with ethanol, separated, and dried to obtain N-trimethyl chitosan; wherein the degree of quaternization substitution of N-trimethyl chitosan is 10 to 20%; preferably Yes, chitosan, sodium iodide and N-methyl-2-pyrrolidone are mixed at a mass ratio of 1-2:3-4:30-40 and reacted at 50-70°C for 0.5-2 hours in the dark to obtain a reaction solution . Further preferably, adding the first sodium hydroxide solution and methyl iodide to the reaction solution with a mass fraction of 5 to 20% and reacting for 1 to 2 hours to obta...

Embodiment 1

[0044] The present embodiment provides a kind of N-trimethyl chitosan microsphere, and its specific preparation method is as follows:

[0045] S101, prepare N-trimethyl chitosan solution with a mass fraction of 0.5% (quaternization degree of substitution 14.6%); mix chitosan, sodium iodide and N-methyl-2-pyrrolidone at 2:4: Mix at a mass ratio of 40 and react in the dark at 60°C for 1 h to obtain a reaction solution, add 20 ml of the first sodium hydroxide solution with a mass fraction of 10% and 20 ml of methyl iodide to react for 1 to 2 hours to obtain a solution, and then add the solution Precipitate, separate and dry with ethanol to obtain N-trimethyl chitosan, and dissolve N-trimethyl chitosan in water to prepare a N-trimethyl chitosan solution with a mass fraction of 0.5%; wherein the shell The viscosity of polysaccharide is 0.48Pa·s;

[0046] S102, the N-trimethyl chitosan solution that mass fraction is 0.5% utilizes the nozzle system of compressed air machine to use t...

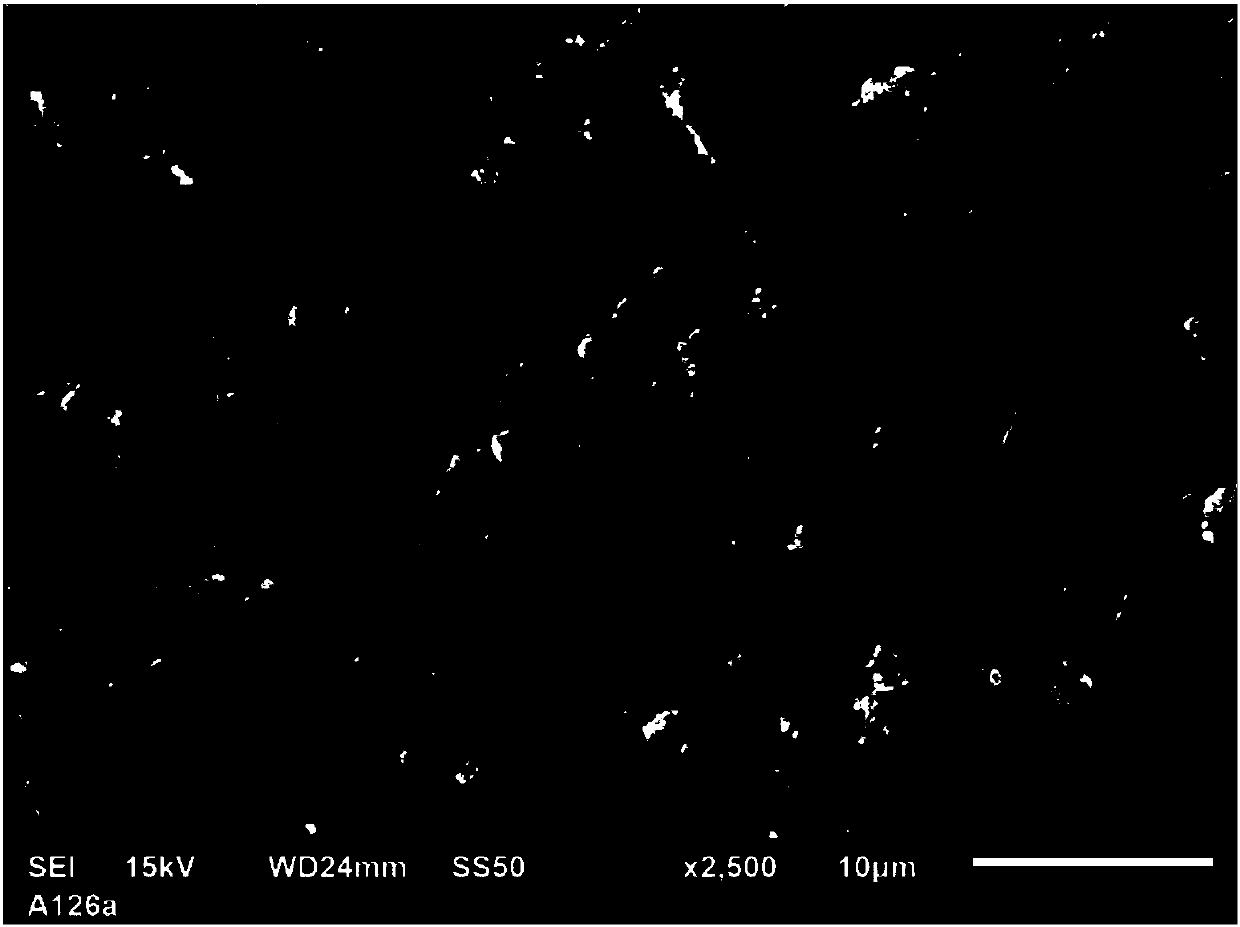

Embodiment 2

[0050] The present embodiment provides a kind of N-trimethyl chitosan microsphere, and its specific preparation method is as follows:

[0051] S201, prepare N-trimethyl chitosan solution with a mass fraction of 2% (quaternization degree of substitution 14.6%); mix chitosan, sodium iodide and N-methyl-2-pyrrolidone at 2:4: Mix at a mass ratio of 40 and react in the dark at 60°C for 1 h to obtain a reaction solution, add 20 ml of the first sodium hydroxide solution with a mass fraction of 10% and 20 ml of methyl iodide to react for 1 to 2 hours to obtain a solution, and then add the solution Precipitate, separate and dry with ethanol to obtain N-trimethyl chitosan, and dissolve N-trimethyl chitosan in water to prepare a N-trimethyl chitosan solution with a mass fraction of 2%; wherein the shell The viscosity of polysaccharide is 0.54Pa·s;

[0052] S202, the mass fraction is that 2% N-trimethyl chitosan aqueous solution utilizes the nozzle system of compressed air machine to use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com