A kind of nano-nickel disulfide material and its preparation method and application

A nickel disulfide and nanotechnology, which is applied to nanometer nickel disulfide materials and their preparation and application fields, can solve the problems of unsuitability for large-scale production, low discharge voltage, low decomposition temperature, etc. Capacity and specific energy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

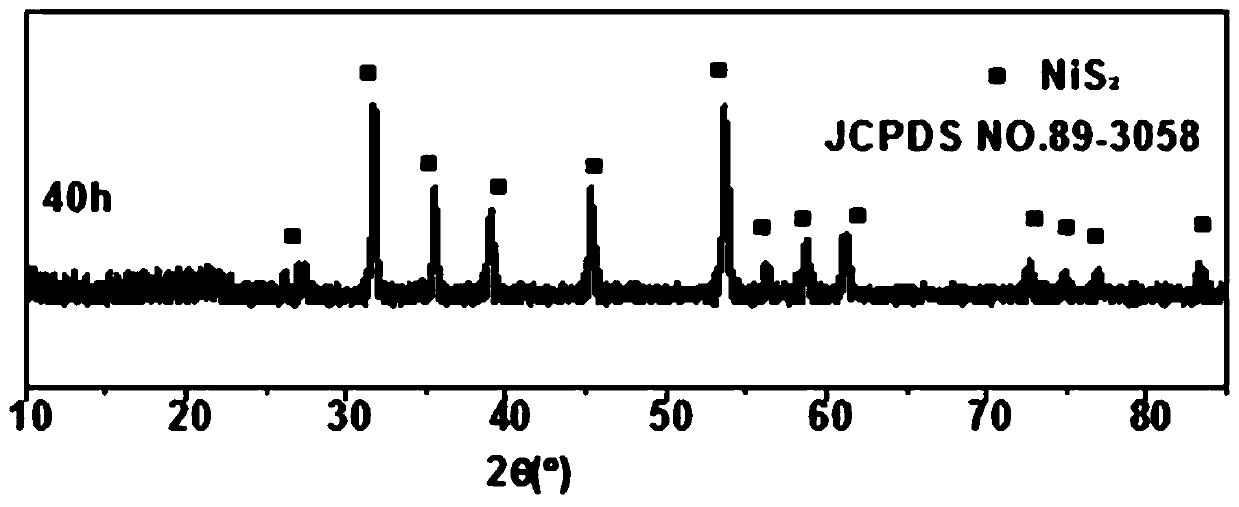

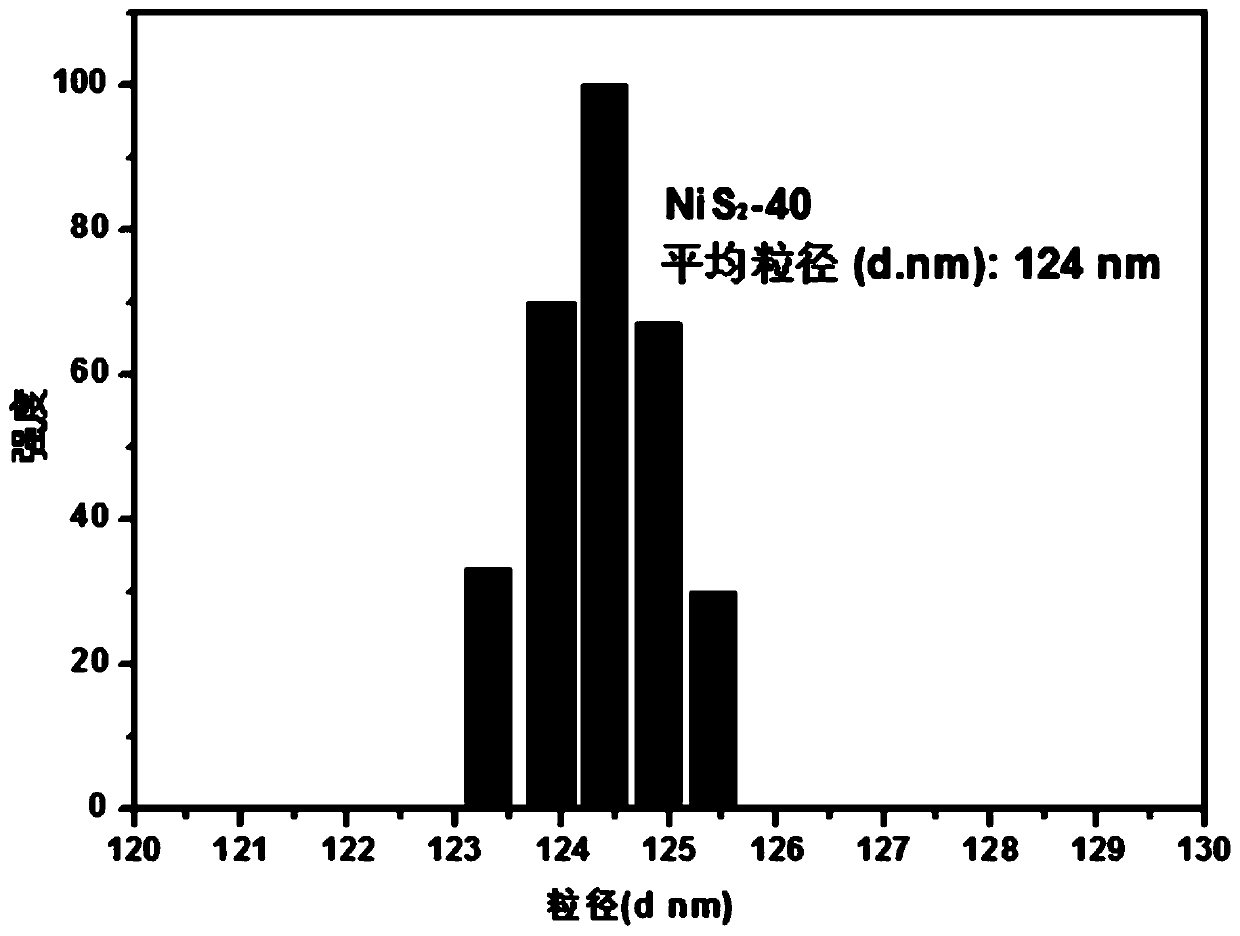

Embodiment 1

[0032] Import nickel powder and sublimated sulfur powder into the agate tank at a mass ratio of 1:1.2, add agate balls at a ratio of 10:1 to the ball to material ratio, ball mill at a speed of 450r / min for 10 hours, and then put the ball abrasives into vacuum drying Dry in an oven for 5 hours, and finally seal and press in a graphite mold. Under an Ar protective atmosphere, raise the temperature to 400°C at a heating rate of 5°C / min, keep it warm for 2h, cool down to room temperature naturally, take out the sintered sample and grind it for storage. The XRD analysis of the calcined powder shows that the pure phase NiS can be obtained after ball milling and calcining at low temperature 2 , the Scherrer formula calculates that the grain size is about 52nm ( figure 1 ). Laser particle size analyzer test powder particle size average size is 124nm ( figure 2 ). Nano-NiS 2 Matched with LiB negative electrode and ternary electrolyte (LiF-LiCl-LiBr) to prepare a monothermal batter...

Embodiment 2

[0034] Import nickel powder and sublimated sulfur powder into the agate tank at a mass ratio of 1:1.7, add agate balls at a ball-to-material ratio of 10:1, ball mill at a speed of 400r / min for 30 hours, and then put the ball abrasives into vacuum drying Dry in an oven for 3 hours, and finally seal and press in a graphite mold. Under an Ar protective atmosphere, raise the temperature to 500°C at a heating rate of 5°C / min, keep it warm for 0.5h, cool down to room temperature naturally, take out the sintered sample and grind it for storage. The XRD analysis of the calcined powder shows that the ball milling low temperature calcination can obtain the pure phase NiS 2 , the grain size analyzed by transmission electron microscopy is about 80nm ( image 3 ). Nano-NiS 2 Matched with LiB negative electrode and ternary electrolyte (LiF-LiCl-LiBr) to prepare a monothermal battery system and at 0.1A cm -2 --Discharge at 500°C ( Figure 4 ), the test results show that nano-NiS 2 The s...

Embodiment 3

[0036] Import nickel powder and sublimated sulfur powder into the agate tank at a mass ratio of 1:2, add agate balls at a ratio of 10:1 to the ball to material ratio, ball mill at a speed of 350r / min for 40 hours, and then put the ball abrasives into vacuum drying Dry it in the oven for 4 hours, and finally seal and press it in a graphite mold. Under an Ar protective atmosphere, raise the temperature to 350°C at a heating rate of 5°C / min, keep it warm for 4 hours, and cool it down to room temperature naturally. Take out the sintered sample and grind it for storage. The XRD analysis of the calcined powder shows that the ball milling low temperature calcination can obtain the pure phase NiS 2 , the laser particle size analyzer test shows that the particle size is about D90≤470nm, and the specific surface test shows that nano-sized NiS 2 The specific surface area is much higher than the micron level, reaching 33.06m 2 g -1 . Nano-NiS 2 Matched with LiB negative electrode and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com