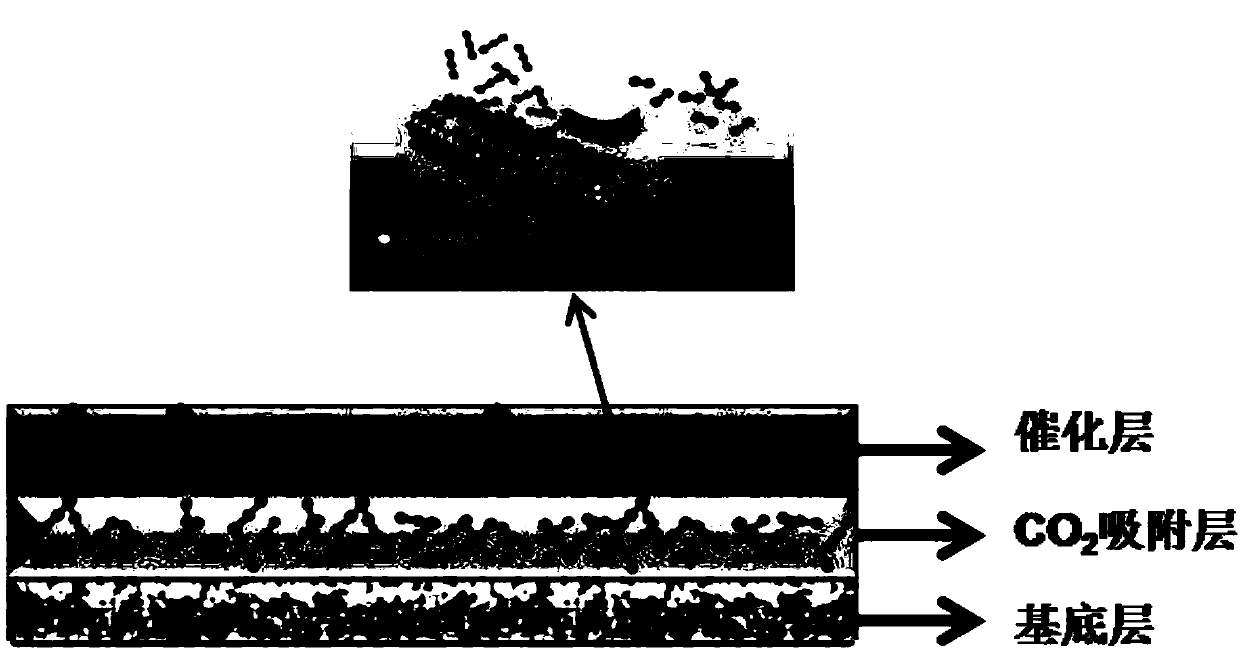

Electrode for electroreduction of carbon dioxide, and preparation and application thereof

A technology of electrodes and heteroatoms, which is applied in the field of electrodes for carbon dioxide electroreduction, can solve the problems of less applied research, achieve the effects of improving transmission, increasing effective active area, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

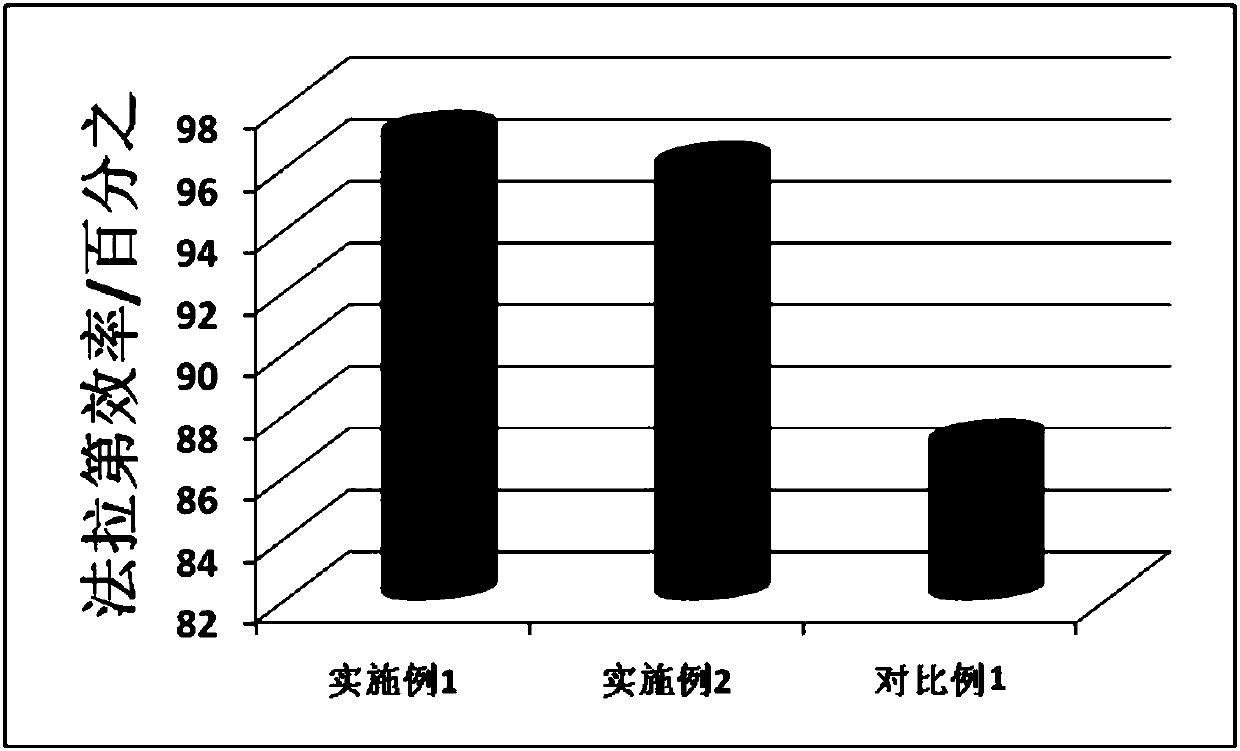

Embodiment 1

[0042] Toray060 carbon paper was treated in the air at 550°C, and then degreased and cleaned in ethanol as the base; 50mg of KB300, 4mg of ethylenediamine compound and 30mg of binder PTFE were blended in 1:4 ethanol: In a mixed solvent of water, an electrode slurry is obtained, wherein the ratio of solid matter to solvent is 20 mg solid / ml solvent; the slurry is coated on the surface of the treated carbon substrate by scraping, and dried at 60 degrees Celsius. The electrode was prepared to obtain CO 2 Capture layer; after the carbon nanotubes are treated in a high-temperature ammonia atmosphere, the temperature is controlled at 900 ° C, and the treatment time is controlled at 3 h; where NH 3 The intake flow rate is controlled at 100ml / min, and nitrogen-doped nanotubes are prepared; take 50mg of nitrogen atom-doped nanotubes (nitrogen content 0.8wt%), add 150mg of isopropanol, oscillate and mix until uniform in ultrasonic waves, and then add 20mg Ferric phthalocyanide, continu...

Embodiment 2

[0044] Toray060 carbon paper was treated in the air at 550°C, and then degreased and cleaned in ethanol as a substrate; 50mg of carbon nanotubes, 4mg of hexamethylenediamine compound and 30mg of binder PTFE were blended in a 1:3 In the mixed solvent of ethanol: water, the electrode slurry is obtained, wherein the ratio of solid matter to solvent is 20 mg solid / ml solvent; the slurry is coated on the surface of the treated carbon substrate by scraping, and baked at 60 degrees Celsius Dry the electrode and prepare the CO 2 Capture layer; after the carbon nanotubes are treated in a high-temperature ammonia atmosphere, the temperature is controlled at 900 ° C, and the treatment time is controlled at 3 h; where NH 3 The intake flow rate is controlled at 100ml / min, and nitrogen-doped nanotubes are prepared; take 50mg of nitrogen atom-doped nanotubes (nitrogen content 0.8wt%), add 150mg of isopropanol, oscillate and mix until uniform in ultrasonic waves, and then add 20mg Ferric pht...

Embodiment 3

[0046] The carbon felt is treated in the air at 550°C, and then degreased and cleaned in ethanol as a substrate; 50mg of carbon nanotubes, 4mg of hexamethylenediamine compound and 30mg of binder PTFE are blended in 1:3 ethanol : In a mixed solvent of water, an electrode slurry is obtained, wherein the ratio of solid matter to solvent is 20 mg solid / ml solvent; the slurry is coated on the surface of the treated carbon substrate by scraping, and dried at 60 degrees Celsius The electrode is prepared, and the CO 2 Capture layer; after the carbon nanotubes are treated in a high-temperature ammonia atmosphere, the temperature is controlled at 900 ° C, and the treatment time is controlled at 3 h; where NH 3 The intake flow rate is controlled at 100ml / min, and nitrogen-doped nanotubes are prepared; take 50mg of nitrogen atom-doped nanotubes (nitrogen content 0.8wt%), add 150mg of isopropanol, oscillate and mix until uniform in ultrasonic waves, and then add 20mg Vitamin B12, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com