Negative capacitance-based surrounding gate field effect transistor and manufacturing method thereof

A technology of a field effect transistor and a manufacturing method, which is applied in the field of gate-around field effect transistors based on negative capacitance and its manufacturing field, can solve the problems of complex manufacturing process and high sub-threshold swing of field effect transistors, achieve simple manufacturing process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

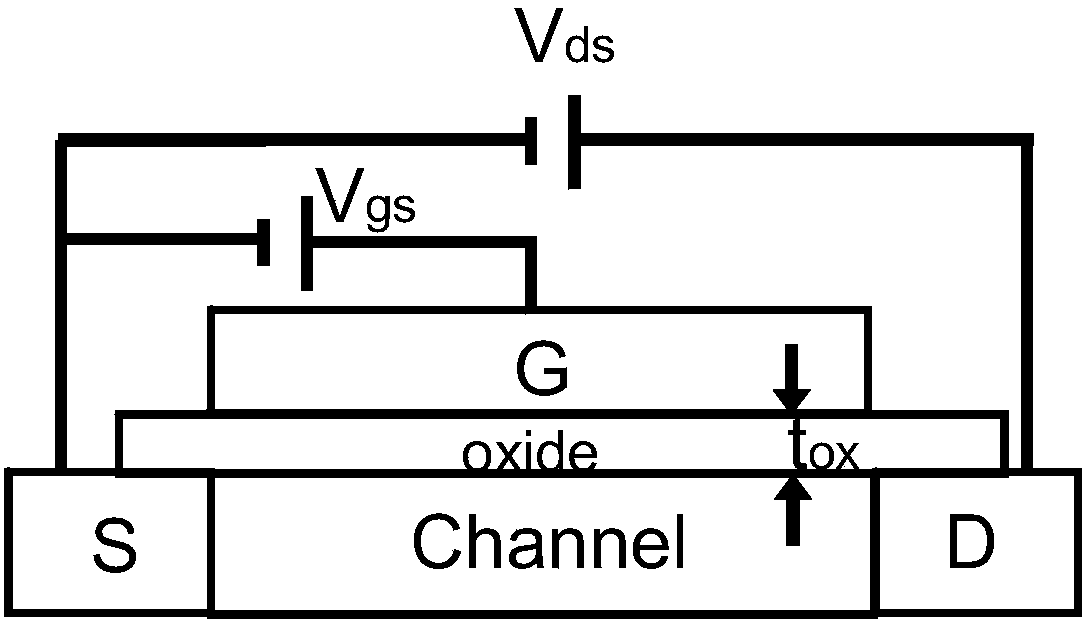

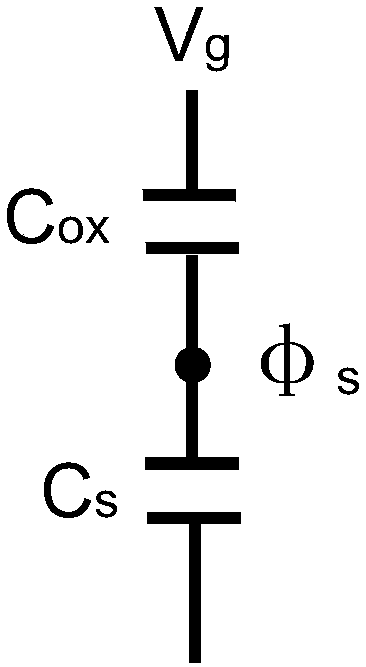

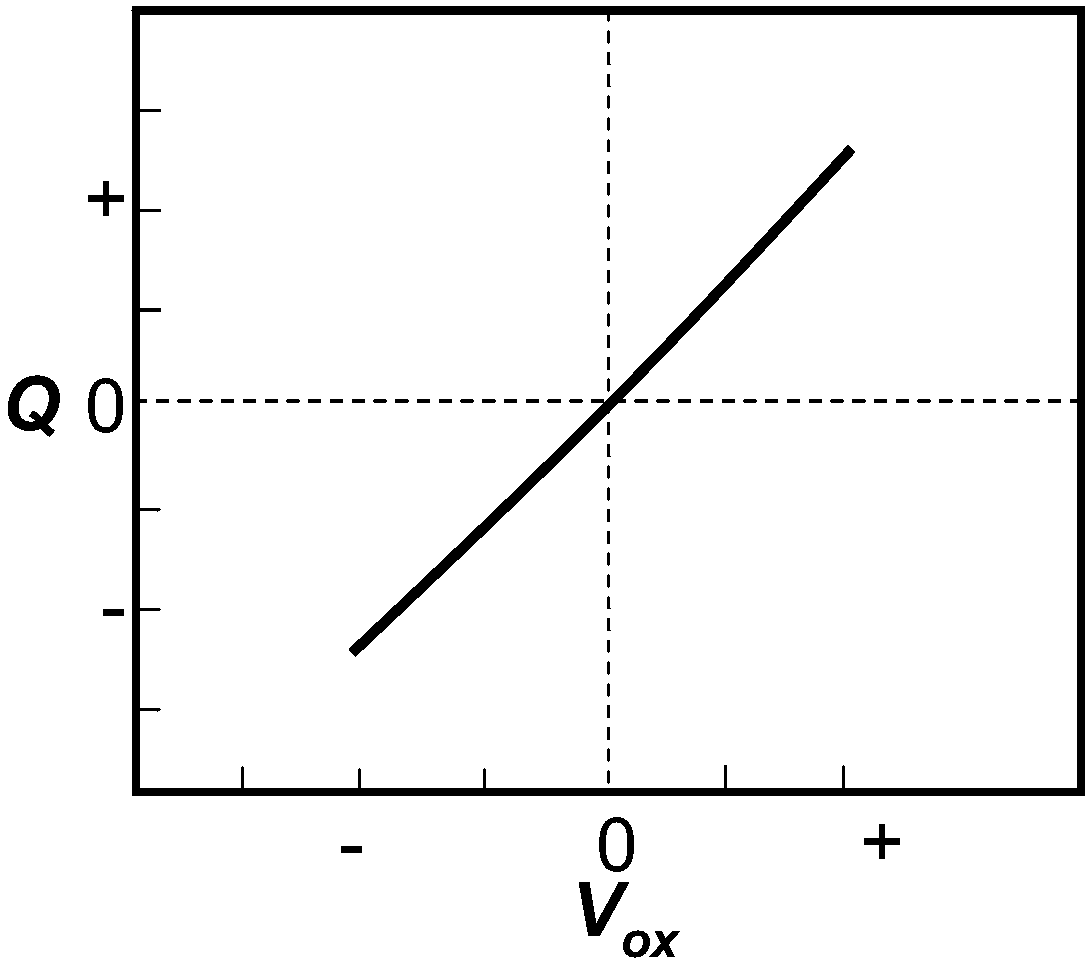

[0074] The present invention provides a gate-all-around field effect transistor based on negative capacitance, wherein a ferroelectric material layer is formed between the high-K dielectric layer and the metal gate layer of the gate structure of the gate-all-around field effect transistor based on negative capacitance; The layer of ferroelectric material has a negative capacitance.

[0075] Specifically, a ferroelectric material refers to a dielectric material that has spontaneous polarization within a certain temperature range, and the direction of the spontaneous polarization can be changed by changing the direction of an applied electric field.

[0076] As an example, the material of the ferroelectric material layer includes HfZrO 2 (zirconium hafnium oxide), PZT (lead zirconate titanate, the chemical formula is Pb(Zr,Ti)O 3 ), SBT (strontium bismuth tantalate, the chemical formula is SrBi 2 TaO 9 ), BRT ((Bi,R) obtained by doping rare earth elements R such as La, Nd, et...

Embodiment 2

[0087] The present invention also provides a method for manufacturing a gate-all-around field effect transistor based on negative capacitance, comprising the following steps:

[0088] First execute step S1: Figure 8 As shown, an SOI substrate including a Si substrate 1 , an insulating buried layer 2 and a top layer of silicon 3 is provided sequentially from bottom to top.

[0089] As an example, the insulating buried layer 2 is made of silicon oxide, and its thickness ranges from 150-350 nm. The thickness range of the top layer silicon 3 is 50-90nm.

[0090] Then execute step S2: as Figure 9-Figure 11 As shown, the top layer of silicon 3 is patterned, and at least one Si nanowire 4 is formed in the top layer of silicon 3 . in, Figure 9 Shown as a top view of the structure obtained in this step, Figure 10 shown as Figure 9 The A-A' direction sectional view of the structure shown, Figure 11 shown as Figure 9 B-B' sectional view of the structure shown.

[0091] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com