Composite nano-microsphere having drug controlled release performance, and preparation method and application thereof

A nano-composite, drug-controlled release technology, applied in the field of biomedical materials, can solve the problems of short drug maintenance time, low drug utilization rate, large toxic and side effects, etc., achieve strong pH and temperature stimuli responsiveness, reduce drug delivery The effect of frequency, high drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

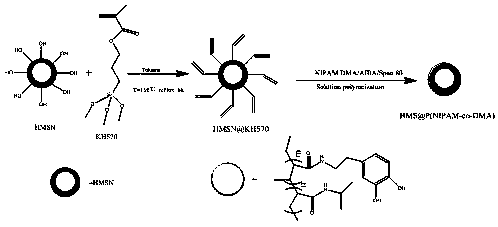

[0063] The preparation of embodiment 1 N-propenyl dopamine DMA

[0064] The preparation method of N-propenyl dopamine DMA is as follows:

[0065] Weigh 2 parts by weight of sodium tetraborate and 0.8 parts by weight of sodium bicarbonate, place them in a three-necked flask, add 50 parts by weight of distilled water at the same time, pass in nitrogen to evacuate, stir at room temperature for 30 minutes, and remove oxygen. Weigh 1 part by weight of dopamine hydrochloride, quickly add it to the above-mentioned three-necked flask, measure 5 parts by weight of 10% tetrahydrofuran solution of methacrylic anhydride, and quickly drop it into the reaction mixture solution, while using 1mol / L NaOH solution The pH of the reaction mixture was controlled to keep it at pH>8, and the reaction was continued for 16 h.

[0066] After the reaction was completed, it was extracted with ethyl acetate, and the aqueous layer was collected. The pH of the aqueous layer was adjusted to 4 Dry overnight...

Embodiment 2

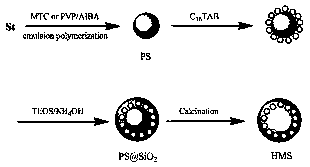

[0067] Example 2 Preparation of Polystyrene Microsphere Emulsion 1

[0068] Take by weighing 10 parts by weight of styrene and 90 parts by weight of water and place them in a three-necked flask, under mechanical stirring, add 0.3 parts by weight of the dispersant methacryloyloxyethyltrimethylammonium chloride (MTC, 75%), stir 30min. Under nitrogen protection, raise the temperature to 70°C, add 0.25 parts by weight of initiator azobisisobutylamidine hydrochloride, and keep stirring for 24 hours to obtain polystyrene microsphere emulsion, and use dynamic light scattering DLS to test its particle size and Dispersion index PDI (PDI<0.05 indicates good monodispersity of PS microspheres), the test results are shown in Table 1.

Embodiment 3

[0069] Example 3 Preparation of Polystyrene Microsphere Emulsion 2

[0070] Weigh 10 parts by weight of styrene, 3 parts by weight of polyvinylpyrrolidone (PVPK29-K30) and 90 parts by weight of water and place them in a three-necked flask, fully mechanically stir the reactants to mix evenly, and simultaneously introduce Ar gas for bubbling to remove oxygen for 30 minutes, Slowly heat up to 60°C, and slowly add 10 parts by weight of an aqueous solution of azobisisobutylamidine hydrochloride (AIBA=0.26 parts by weight) dropwise with a constant pressure dropping funnel. Then in Ar atmosphere, reflux reaction for 24h to obtain polystyrene microsphere emulsion, and use dynamic light scattering DLS to test its particle size and distribution coefficient PDI (PDI<0.05 indicates good monodispersity of PS microspheres), the test results are shown in Table 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com