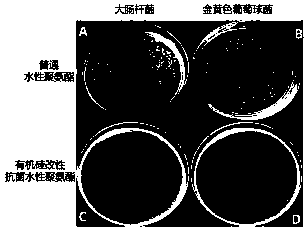

Preparation method of organic silicon modified antibacterial waterborne polyurethane

A technology of water-based polyurethane and silicone, which is applied in the field of preparation of silicone-modified antibacterial water-based polyurethane, which can solve problems such as poor mechanical strength, easy heating and softening, and environmental pollution, so as to improve mechanical properties, water resistance, and weather resistance And water resistance, the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, a kind of preparation method of organosilicon modified antibacterial waterborne polyurethane, the steps are as follows:

[0044] 1) Dehydrating polyethylene glycol with an average molecular weight of 200 under vacuum for 3 hours at 85°C to obtain product A;

[0045] 2) Lower the temperature of product A to 35°C, then add hexamethylene diisocyanate and catalyst I (dibutyltin dilaurate), and react with stirring for 4 hours under the protection of nitrogen to obtain product B;

[0046] 3) Add dihydroxy half ester to product B, and react at 40°C for 9 hours to obtain product C;

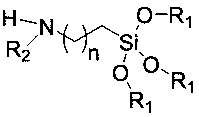

[0047] 4) Lower the temperature of product C to 35°C, add acetone to reduce the viscosity until the polymer does not stick to the stirring paddle, and add the structural formula as attached figure 2 alkoxysilane, where n is 1, R 1 with R 2 Respectively for an alkyl group containing 1 carbon atom, reacted for 2 hours to obtain the D product;

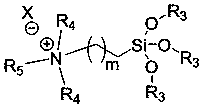

[0048] 5) Add the structural formula i...

Embodiment 2

[0050] Embodiment 2, a kind of preparation method of organosilicon modified antibacterial waterborne polyurethane, the steps are as follows:

[0051] 1) Vacuum dehydration of polyether diol with an average molecular weight of 1500 at 95°C for 2.5 hours to obtain product A;

[0052] 2) Lower the temperature of product A to 45°C, then add isophorone diisocyanate and catalyst I (dibutyltin dilaurate), and react with stirring for 3.5 hours under the protection of nitrogen to obtain product B;

[0053] 3) Add 1,4-butanediol and sodium ethylenediaminoethanesulfonate to product B, and react at 50°C for 7 hours to obtain product C;

[0054] 4) Lower the temperature of product C to 38°C, add acetone to reduce the viscosity until the polymer does not stick to the stirring paddle, and add the structural formula as attached figure 2 alkoxysilane, where n is 4, R 1 with R 2 Respectively be the alkyl group that contains 3 carbon atoms, react 4 hours, obtain D product;

[0055] 5) Add th...

Embodiment 3

[0057] Embodiment 3, a kind of preparation method of organosilicon modified antibacterial waterborne polyurethane, the steps are as follows:

[0058] 1) Dehydrating polycarbonate diol with an average molecular weight of 3000 under vacuum for 2 hours at 105°C to obtain product A;

[0059] 2) Lower the temperature of product A to 55°C, then add cyclohexane dimethylene diisocyanate and catalyst I (dibutyltin dilaurate), and react with stirring for 2.5 hours under the protection of nitrogen to obtain product B;

[0060] 3) Add ethanolamine and methyldiethanolamine to product B, and react at 65°C for 5 hours to obtain product C;

[0061] 4) Lower the temperature of product C to 40°C, add acetone to reduce the viscosity until the polymer does not stick to the stirring paddle, and add the structural formula as attached figure 2 alkoxysilane, where n is 12, R 1 with R 2 Respectively containing 10 carbon atoms of the alkyl group, reacted for 7 hours to obtain the D product;

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com