Preparation method and applications of magnetically modified loess adsorbent

An adsorbent, loess technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of failing to meet the adsorption requirements of wastewater treatment, the adsorption performance of adsorbents and other problems, and achieve cation exchange performance. Excellent, improved adsorption performance, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of Magnetically Modified Shaanxi Loess Adsorbent

[0037] Weigh 4.5g of FeCl 3 ·6H 2 O, the KOH of 1.75g is dissolved in the ethylene glycol of 100mL, and constant stirring speed is 300 revs / min, stirs 5h, obtains yellow-brown suspension; The temperature is 350°C, the time is 1.5h), acid activation (activate it with hydrochloric acid with a concentration of 3wt%, the liquid-solid mass ratio of hydrochloric acid and heat-activated loess in northern Shaanxi is 15:1, and at 100°C Control the stirring speed to 400 revs / min, the northern Shaanxi loess 1.349g after the stirring time is 8h), continue to control the stirring speed, mix and stir for 3h, and obtain the suspension; the above suspension is encapsulated in a polytetrafluoroethylene reactor, React at 200°C for 8 hours; take the black solid and wash it 3 times with water and ethanol, magnetically separate, dry, and grind to obtain magnetically modified Shaanxi loess.

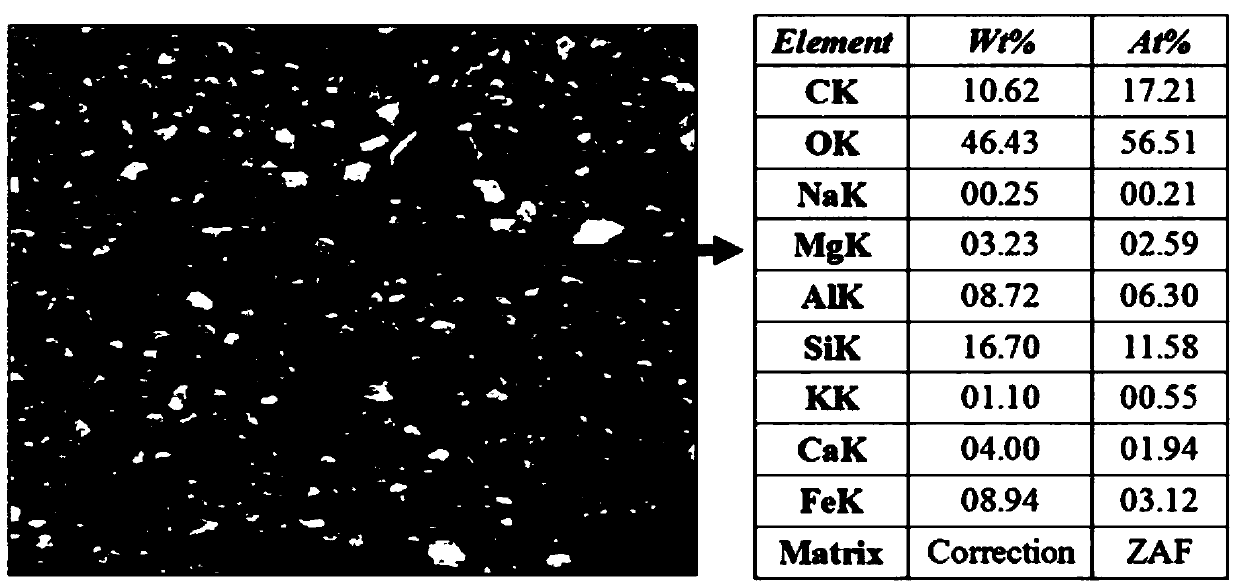

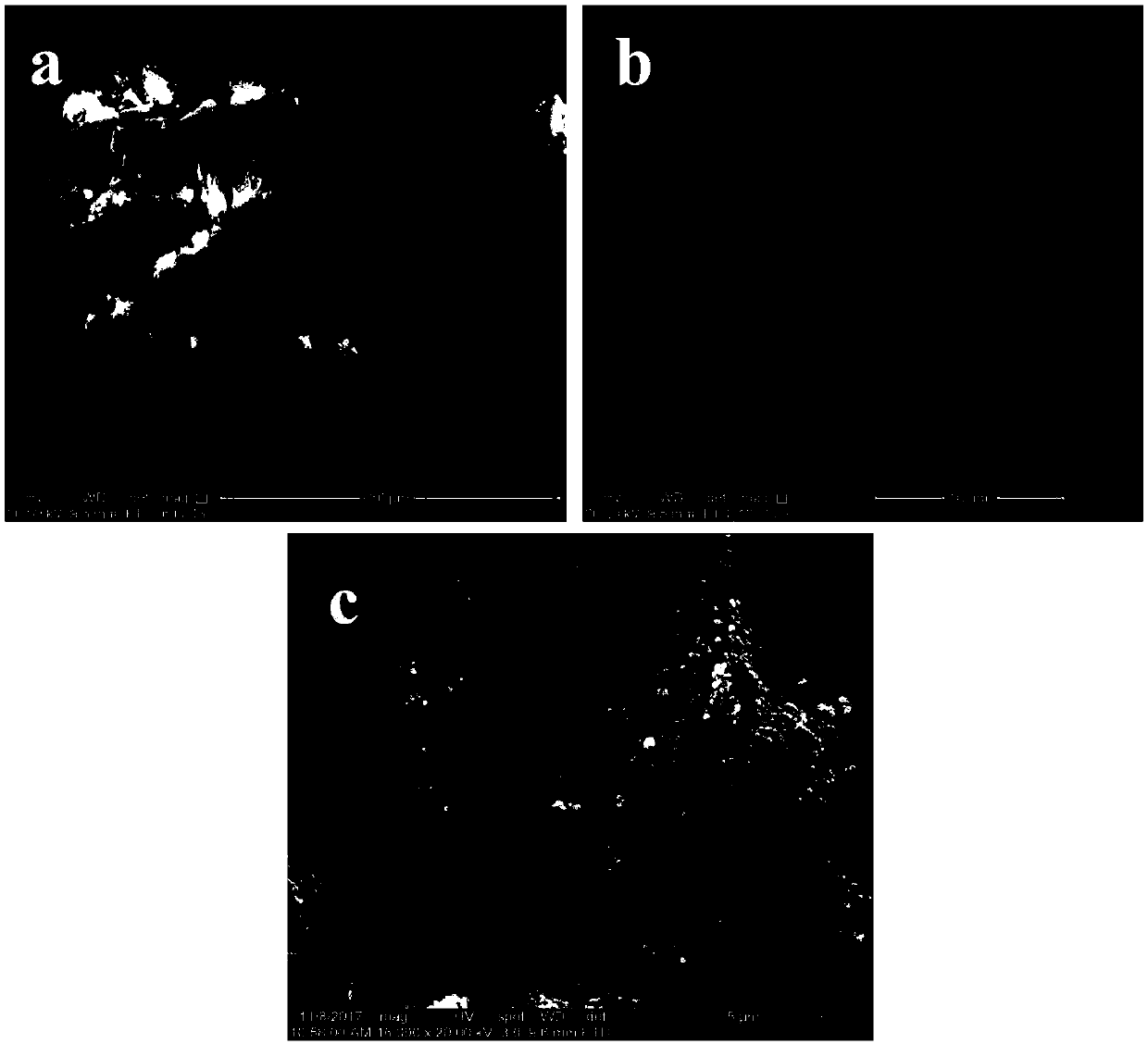

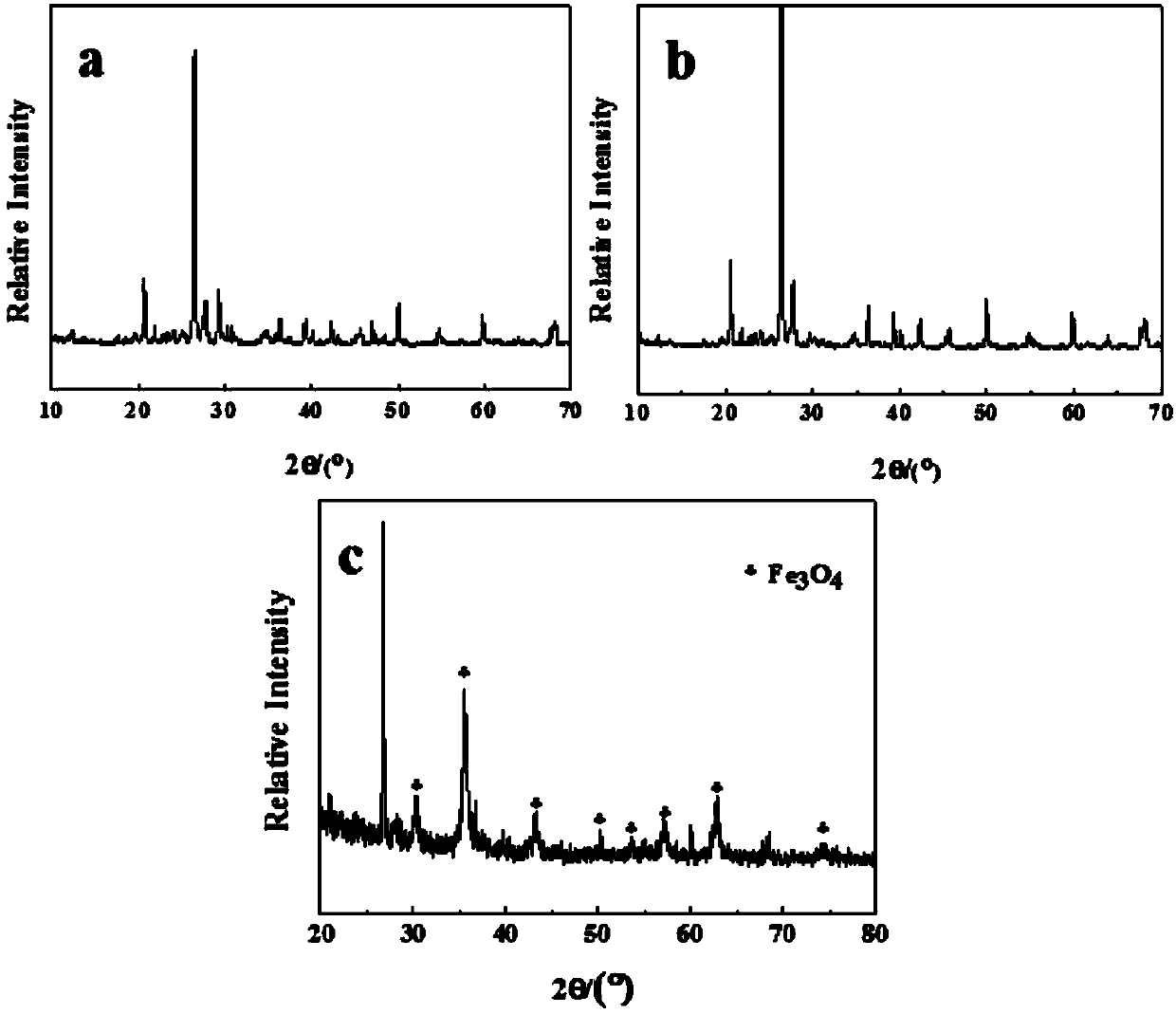

[0038] 2. Phase composition, ...

Embodiment 2 36

[0072] 1. Preparation of Magnetically Modified Shaanxi Loess Adsorbent

[0073] Weigh 5.2g of FeCl 3 ·6H 2 O, the KOH of 1.92g is dissolved in the ethylene glycol of 130mL, and constant stirring speed is 300 revs / min, stirs 6h, obtains yellow-brown suspension; The temperature is 350°C, the time is 1.5h), acid activation (activate it with hydrochloric acid with a concentration of 3wt%, the liquid-solid mass ratio of hydrochloric acid and heat-activated loess in northern Shaanxi is 15:1, and at 100°C Control the stirring speed to 400 revs / min, the northern Shaanxi loess 1.349g after the stirring time is 8h), continue to control the stirring speed, mix and stir for 3h, and obtain the suspension; the above suspension is encapsulated in a polytetrafluoroethylene reactor, React at 180°C for 9 hours; take the black solid and wash it 3 times with water and ethanol, magnetically separate, dry, and grind to obtain magnetically modified Shaanxi loess.

[0074] 2. Determination of adso...

Embodiment 3

[0078] 1. Preparation of Magnetically Modified Shaanxi Loess Adsorbent

[0079] Weigh 5.9g of FeCl 3 ·6H 2O, the KOH of 2.45g is dissolved in the ethylene glycol of 150mL, and constant stirring speed is 350 revs / min, stirs 5h, obtains yellow-brown suspension; The temperature is 350°C, the time is 1.5h), acid activation (activate it with hydrochloric acid with a concentration of 3wt%, the liquid-solid mass ratio of hydrochloric acid and heat-activated loess in northern Shaanxi is 15:1, and at 100°C Control the stirring speed to 400 revs / min, the northern Shaanxi loess 1.349g after the stirring time is 8h), continue to control the stirring speed, mix and stir for 3h, and obtain the suspension; the above suspension is encapsulated in a polytetrafluoroethylene reactor, React at 160°C for 10 hours; take the black solid and wash it 3 times with water and ethanol, magnetically separate, dry, and grind to obtain magnetically modified Shaanxi loess.

[0080] 2. Determination of adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com