A kind of denitration catalyst and preparation method thereof

A technology of denitrification catalyst and catalytic aid, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of small specific surface area of catalysts, so as to avoid damage to human body and environment, improve Effect of specific surface area and pore volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

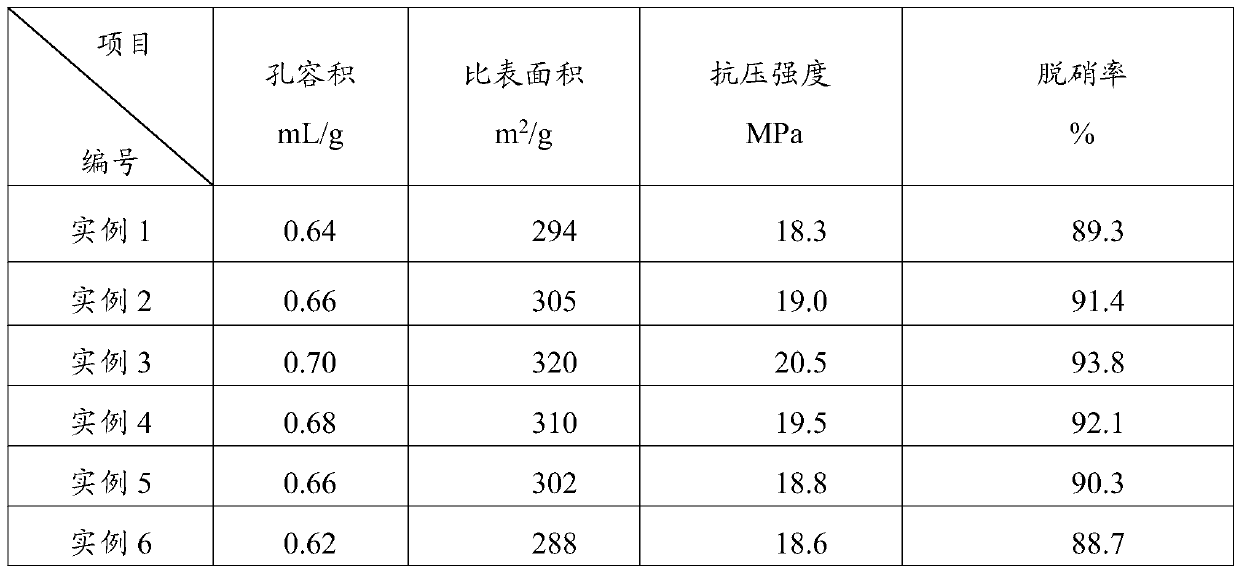

Examples

preparation example Construction

[0026] The invention provides a preparation method of a denitration catalyst, comprising the following steps:

[0027] 1) mixing the nitric acid solution, the sodium metaaluminate solution and the catalytic promoter to obtain a colloidal solution, the catalytic promoter comprising alkali metal silicate and rare earth metal nitrate;

[0028] 2) aging the colloidal solution to obtain pseudo-boehmite containing a catalytic promoter;

[0029] 3) Kneading the pseudo-boehmite containing the catalytic promoter and the nitric acid solution to obtain a honeycomb carrier;

[0030] 4) drying the honeycomb carrier successively and first roasting to obtain a catalyst carrier;

[0031] 5) impregnating and adsorbing the catalyst carrier in a mixed solution of potassium permanganate, ferric nitrate, calcium nitrate and water to obtain the impregnated catalyst carrier;

[0032] 6) The impregnated catalyst carrier is sequentially dried and secondly calcined to obtain a denitration catalyst. ...

Embodiment 1

[0048] (1) Under mechanical stirring, the nitric acid solution with a mass percentage of 10% and the sodium metaaluminate solution with a concentration of 100 g / L as aluminum oxide are continuously gelled in a synthesis kettle, and the reaction temperature is controlled at 60° C. During the neutralization process, catalyst promoters sodium silicate and lanthanum nitrate are added to obtain a colloidal solution.

[0049] (2) The obtained colloidal solution is all moved into the aging tank, aged at 50°C for 60min, after the aging is completed, filtered, the solid product is taken, washed continuously for 5 times with deionized water to obtain the pseudo-boehmite containing the catalytic promoter ;

[0050] (3) kneading the pseudo-boehmite filter cake and 5% dilute nitric acid in a vacuum mud mill, and then extruding into a honeycomb carrier through a vacuum extruder;

[0051] (4) The extruded honeycomb carrier is dried in a drying room at 100°C for 6h, and roasted in a roasting...

Embodiment 2

[0057] (1) Under mechanical stirring, the nitric acid solution with a mass percentage of 35% and the sodium metaaluminate solution with a concentration of 400 g / L as alumina are continuously gelled in a synthesis kettle, and the reaction temperature is controlled at 90° C. In the process of neutralization, catalyst promoters potassium silicate and cerium nitrate are added to obtain a colloidal solution.

[0058] (2) The obtained colloidal solution is all moved into the aging tank, aged at 75°C for 30min, after the aging is completed, filtered, and the solid product is taken, washed continuously with deionized water for 4 times to obtain pseudo-boehmite containing catalytic promoter ;

[0059] (3) kneading the pseudo-boehmite filter cake and 30% dilute nitric acid in a vacuum mud mill, and then extruding into a honeycomb carrier through a vacuum extruder;

[0060] (4) The extruded honeycomb carrier is dried at 105° C. for 6 hours in a drying room, and roasted at 640° C. for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com