One-component moisture cured polyurethane sealant containing novel water removal agent and preparation method of one-component moisture cured polyurethane sealant

A polyurethane sealant and moisture curing technology, which is applied in the field of sealants, can solve the problems of poor control of the amount of water remover, etc., and achieve the effect of improving bubbling phenomenon, little influence of viscosity, and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

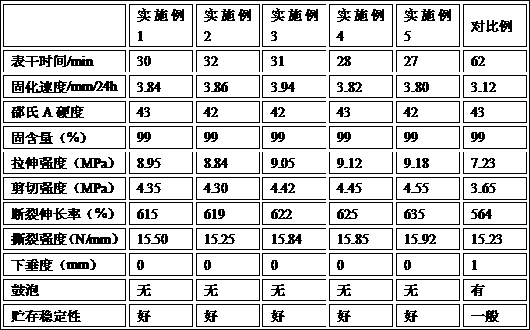

Examples

Embodiment 1

[0058] A one-component moisture-curing polyurethane sealant containing a new type of dewatering agent, in parts by weight, composed of the following raw materials: polyurethane prepolymer 15kg, plasticizer 10kg, dewatering agent a 1kg, dewatering agent b1kg, Packing 10kg, silane coupling agent 0.2kg, catalyst 0.1kg and auxiliary agent 1kg;

[0059] The plasticizer is didecyl phthalate;

[0060] The dewatering agent b is p-toluenesulfonyl isocyanate;

[0061] The filler is obtained by mixing nano calcium carbonate, light calcium carbonate, and carbon black in a mass ratio of 1:2:2;

[0062] The catalyst is dibutyl tin dilaurate;

[0063] The silane coupling agent is A-187;

[0064] The auxiliary agent is obtained by mixing ultraviolet absorber, antioxidant 1010, flame retardant and dispersant in a mass ratio of 1:2:20:1;

[0065] The ultraviolet absorber is ultraviolet absorber UV1; the flame retardant is magnesium hydroxide; the dispersant is glycerol monostearate;

[0066] The polyuretha...

Embodiment 2

[0069] A one-component moisture-curing polyurethane sealant containing a new type of dewatering agent, in parts by weight, composed of the following raw materials: polyurethane prepolymer 70kg, plasticizer 45kg, dewatering agent a10kg, dewatering agent b2kg, filler 60kg, 2kg of silane coupling agent, 1kg of catalyst and 5kg of auxiliary agent;

[0070] The plasticizer is diisononyl phthalate;

[0071] The dewatering agent b is triethyl orthoformate;

[0072] The filler is obtained by mixing heavy calcium carbonate, white carbon black and titanium dioxide in a weight ratio of 1:4:1;

[0073] The catalyst is stannous octoate;

[0074] The silane coupling agent is A-189;

[0075] The auxiliary agent is obtained by mixing ultraviolet absorber, antioxidant 1010, flame retardant and dispersant in a mass ratio of 2:1:40:1;

[0076] The ultraviolet absorber is ultraviolet absorber UV1577; the flame retardant is aluminum hydroxide; the dispersant is glyceryl tristearate;

[0077] The polyurethane ...

Embodiment 3

[0080] A one-component moisture-curing polyurethane sealant containing a new type of dewatering agent, in parts by weight, composed of the following raw materials: polyurethane prepolymer 40kg, plasticizer 25kg, dewatering agent a 6kg, and dewatering agent b1. 2kg, 40kg filler, 1kg silane coupling agent, 0.5kg catalyst and 3kg auxiliary agent;

[0081] The plasticizer is diisononyl cyclohexane 1,2-dicarboxylate;

[0082] The dewatering agent b is calcium oxide;

[0083] The filler is obtained by mixing talc powder and organic bentonite in a mass ratio of 9:1;

[0084] The catalyst is chelated tin;

[0085] The silane coupling agent is A-187;

[0086] The auxiliary agent is obtained by mixing ultraviolet absorber, antioxidant 1010, flame retardant and dispersant in a mass ratio of 1:1:27:1;

[0087] The ultraviolet absorber is obtained by mixing the ultraviolet absorber UV1 and the ultraviolet absorber UV1577 in a mass ratio of 1:4; the flame retardant is obtained by mixing magnesium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com