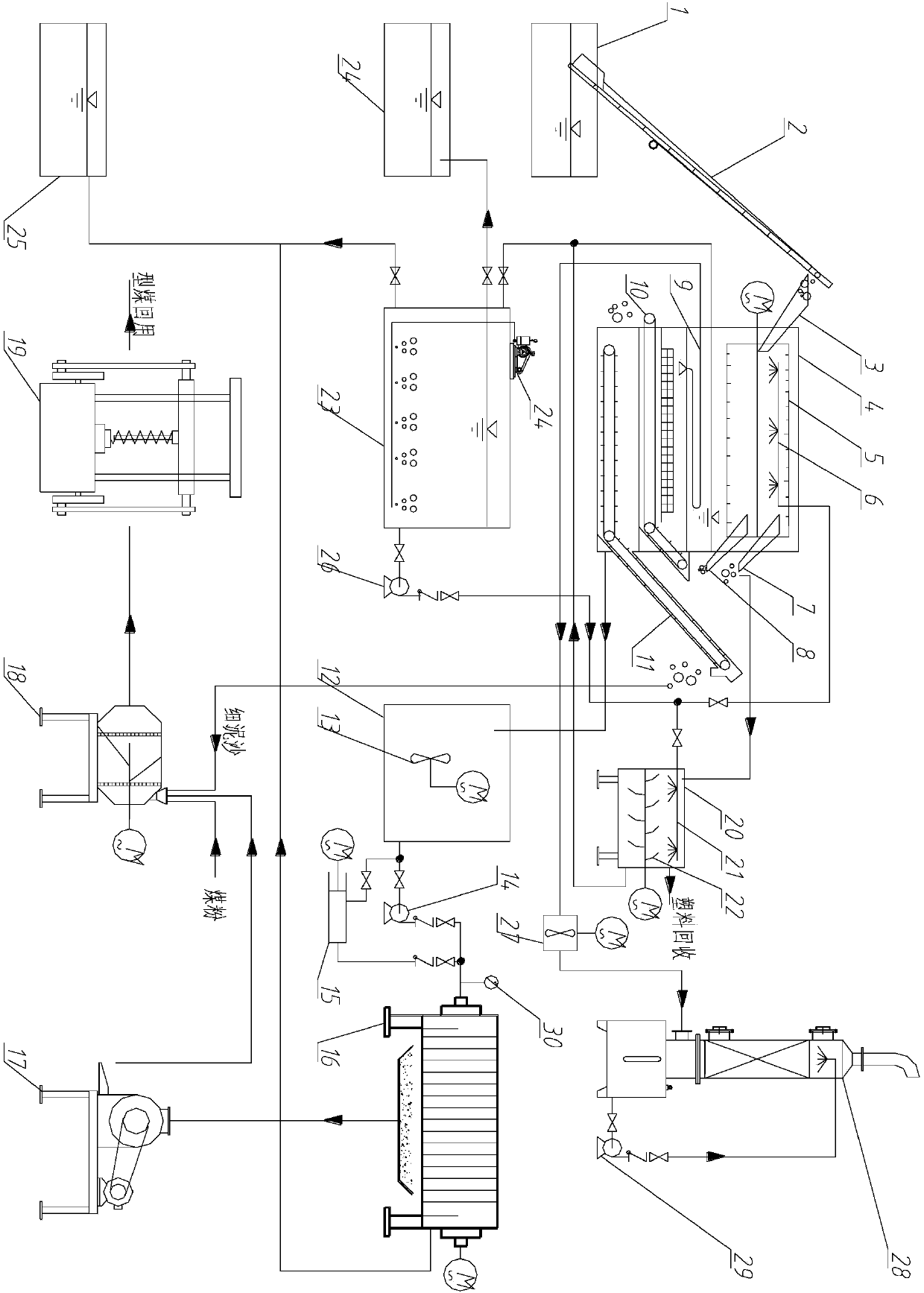

Petrochemical engineering oil sludge treatment device and method

A kind of oil sludge and petrochemical technology, which is applied in the field of petrochemical oil sludge treatment equipment, can solve the problems of backward treatment technology, environmental pollution, high treatment cost, etc., and achieve the effect of simple equipment operation, high degree of automation and stable single operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The amount of oil sludge treated by the equipment is 5m 3 / h, processed according to the flow process shown in Figure 1, a total of 500 tons were processed. The moisture content of the sludge after dehydration by the high-pressure sludge dewatering machine is 40-50%, and the moisture content of the mixed material of the fuel mixer is 45-55%. The working pressure of the thick slurry pump is controlled at 0-0.4MPa, and the working pressure of the high-pressure dehydration is controlled at 0-20MPa.

[0044] The equipment operates continuously and stably, processing 500 tons of oil sludge. The results are shown in Table 2.

[0045] Table 2 Situation after oil sludge treatment

[0046] project

[0047] Among them, the oil content of mud and sand is less than 2%, which meets the requirements for solid waste landfill disposal, and the oil content of sewage is less than 200mg / L, which is returned to the sewage treatment system.

[0048] The smoke emission is shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com