Titanium dioxide plastic film and processing method thereof

A technology of plastic film and titanium dioxide, which is applied in anodic oxidation, metal material coating process, superimposed layer plating, etc., can solve the problems of low porosity of titanium dioxide film and inability to fully exert the photocatalytic effect of titanium dioxide film, and achieve self-cleaning Good effect, easy to implement, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

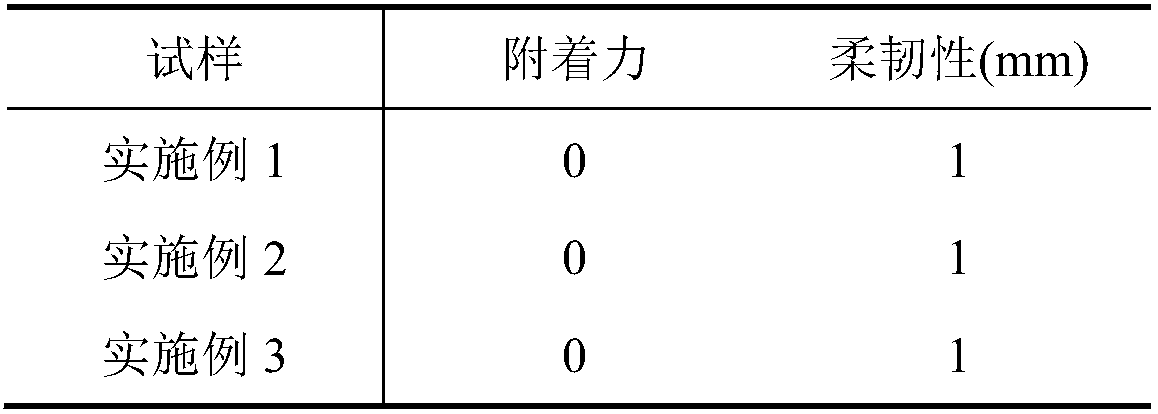

Examples

Embodiment 1

[0033] Preparation of Titanium Dioxide Plastic Film

[0034] The titanium dioxide plastic film comprises a polymer plastic film, a pure aluminum film layer covering the surface of the polymer plastic film, an aluminum oxide film layer with a porous structure generated by oxidation treatment on the surface of the pure aluminum film layer, and deposited on the The titanium dioxide film layer on the aluminum oxide film layer surface, its preparation method comprises the following steps:

[0035] (1) Processing of pure aluminum film layer

[0036] Choose a PE plastic film with a thickness of 20 μm and a width of 1000 mm, and use Nanjing Jiabali JBL-1000K corona treatment machine for corona treatment. The treatment process uses AC220V (± 20%) regulated DC power supply, 6 electrodes, and the electrode gap is 2mm. Continuous single-sided corona treatment is carried out on the film, the treatment voltage range is 15000V, the output power of the corona treatment machine is 6000VA, the...

Embodiment 2

[0045] Preparation of Titanium Dioxide Plastic Film

[0046] The titanium dioxide plastic film comprises a polymer plastic film, a pure aluminum film layer covering the surface of the polymer plastic film, an aluminum oxide film layer with a porous structure generated by oxidation treatment on the surface of the pure aluminum film layer, and deposited on the The titanium dioxide film layer on the aluminum oxide film layer surface, its preparation method comprises the following steps:

[0047] (1) Processing of pure aluminum film layer

[0048] Select a BOPET plastic film with a thickness of 10 μm and a width of 1000 mm, and place the film in Chicheng CCZK-RC vacuum roll-to-roll coating machine. Using a vacuum evaporation process, the surface of the BOPET plastic film is coated with aluminum, and the vacuum chamber is evacuated to a vacuum first. 1.3×10 -2 Pa, the temperature of the evaporation boat is controlled at 1350°C, and the aluminum wire with a diameter of 2mm and a p...

Embodiment 3

[0055] Preparation of Titanium Dioxide Plastic Film

[0056] The titanium dioxide plastic film comprises a polymer plastic film, a pure aluminum film layer covering the surface of the polymer plastic film, an aluminum oxide film layer with a porous structure generated by oxidation treatment on the surface of the pure aluminum film layer, and deposited on the The titanium dioxide film layer on the aluminum oxide film layer surface, its preparation method comprises the following steps:

[0057] (1) Processing of pure aluminum film layer

[0058] Choose a BOPP plastic film with a thickness of 80 μm and a width of 1000 mm, and use Nanjing Jiabali JBL-1000K corona treatment machine for corona treatment. The treatment process uses AC220V (± 20%) regulated DC power supply, 6 electrodes, and the electrode gap is 1mm. Carry out continuous single-sided corona treatment on the film, the treatment voltage is 20000V, the output power of the corona treatment machine is 13000VA, the output ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com