Preparation method of iodine-nitrogen co-doped carbon microspheres

A carbon microsphere, co-doping technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of negative electrode volume discount, reduce material density, etc., achieve good sphericity, avoid density reduction, preparation process Simple and gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a nitrogen-protected glove box, add 1g of cetyltrimethylammonium chloride, 4g of analytically pure iodine and 4ml of ethylenediamine to 6ml of toluene in sequence, stir for 10 minutes, and put the mixture into a volume of 15ml In a stainless steel reaction kettle, seal it; then place the reaction kettle in a crucible boiler, heat it at 300°C for 6 hours, then wait for the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed three times successively with absolute ethanol, dilute hydrochloric acid and distilled water, filtered, and then vacuum-dried at 60°C and 0.1MPa vacuum for 12 hours to obtain iodine-nitrogen co-doped carbon microparticles with high volume specific capacitance. ball.

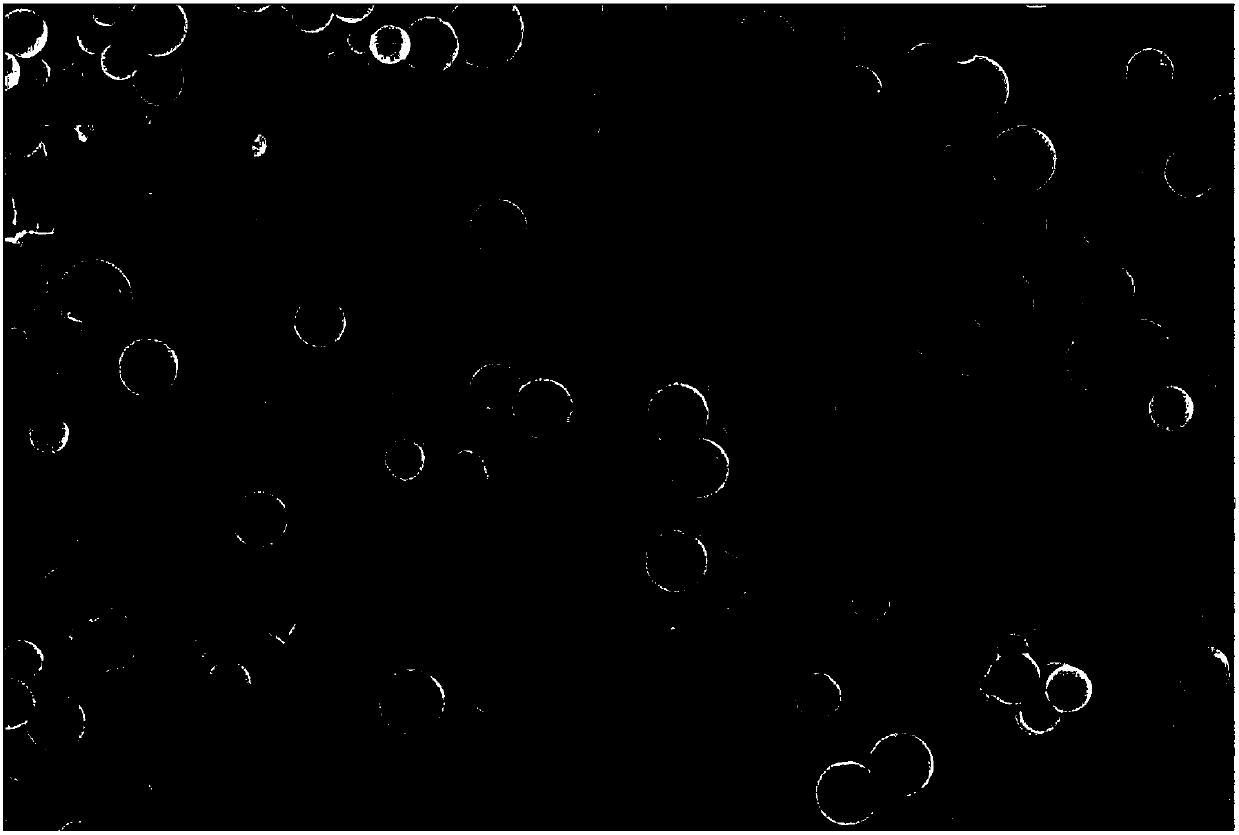

[0023] Such as figure 1 As shown, it can be clearly seen that the surface of the microsphere is smooth and spherical, and its length is between 1 micron and 4 microns.

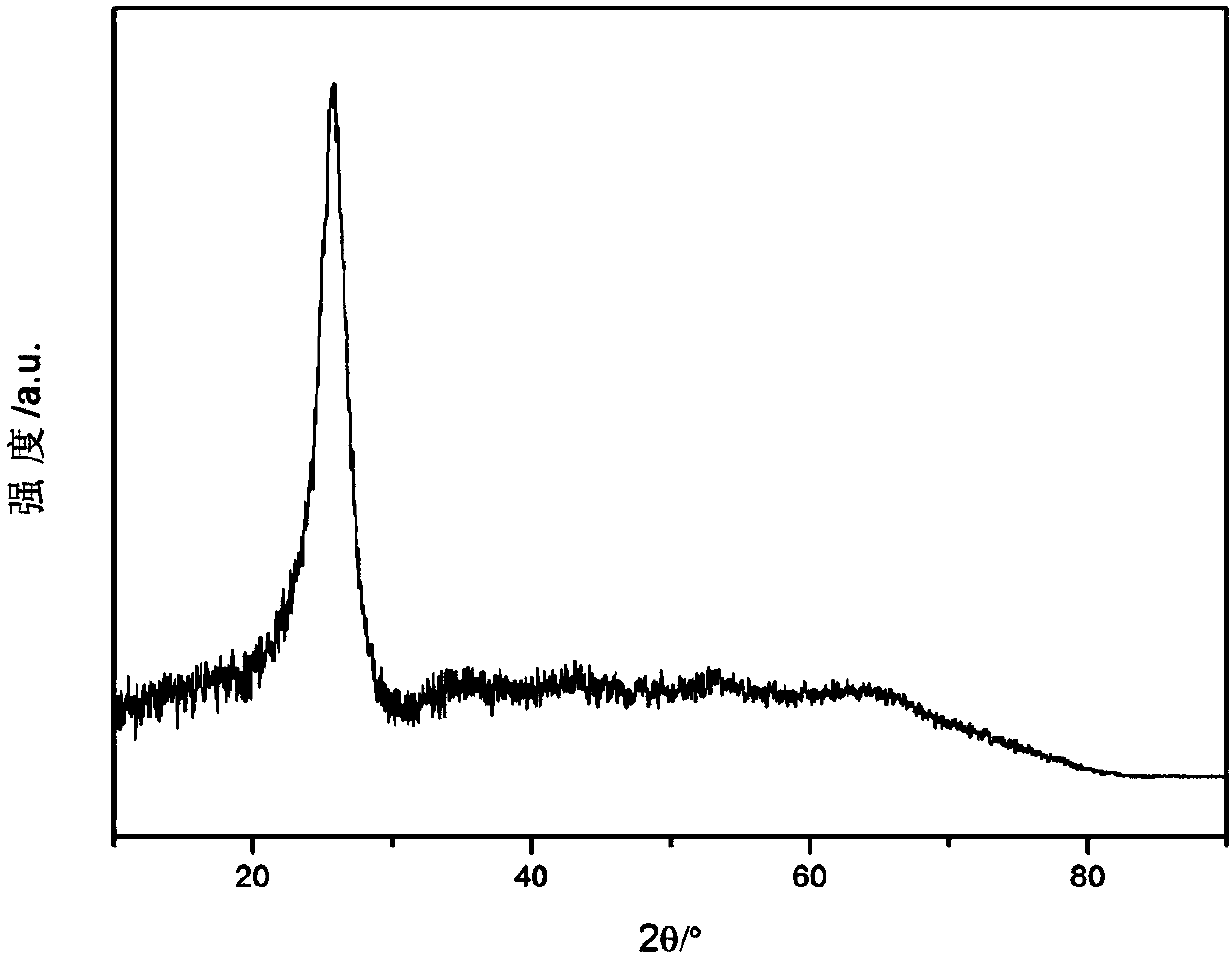

[0024] Such as figure 2 It can be seen that the ...

Embodiment 2

[0026] In a nitrogen-protected glove box, 1.8 grams of cetyltrimethylammonium bromide, 2.1 grams of analytically pure ammonium iodide and 9 ml of pyrrole were added to 6 ml of benzene in turn, stirred for 20 minutes, and the mixture was put into a volume of 45ml stainless steel reaction kettle, sealed; then the reaction kettle was placed in a crucible boiler, heated at 600 ° C for 24 hours, and then the reaction kettle was naturally cooled to room temperature, and the mixture was taken out. The above mixture was washed 5 times with absolute ethanol, dilute hydrochloric acid and distilled water successively, filtered, and then vacuum-dried at 80°C and 0.1MPa vacuum for 10 hours to obtain iodine-nitrogen-doped carbon microparticles with high volume specific capacitance. ball.

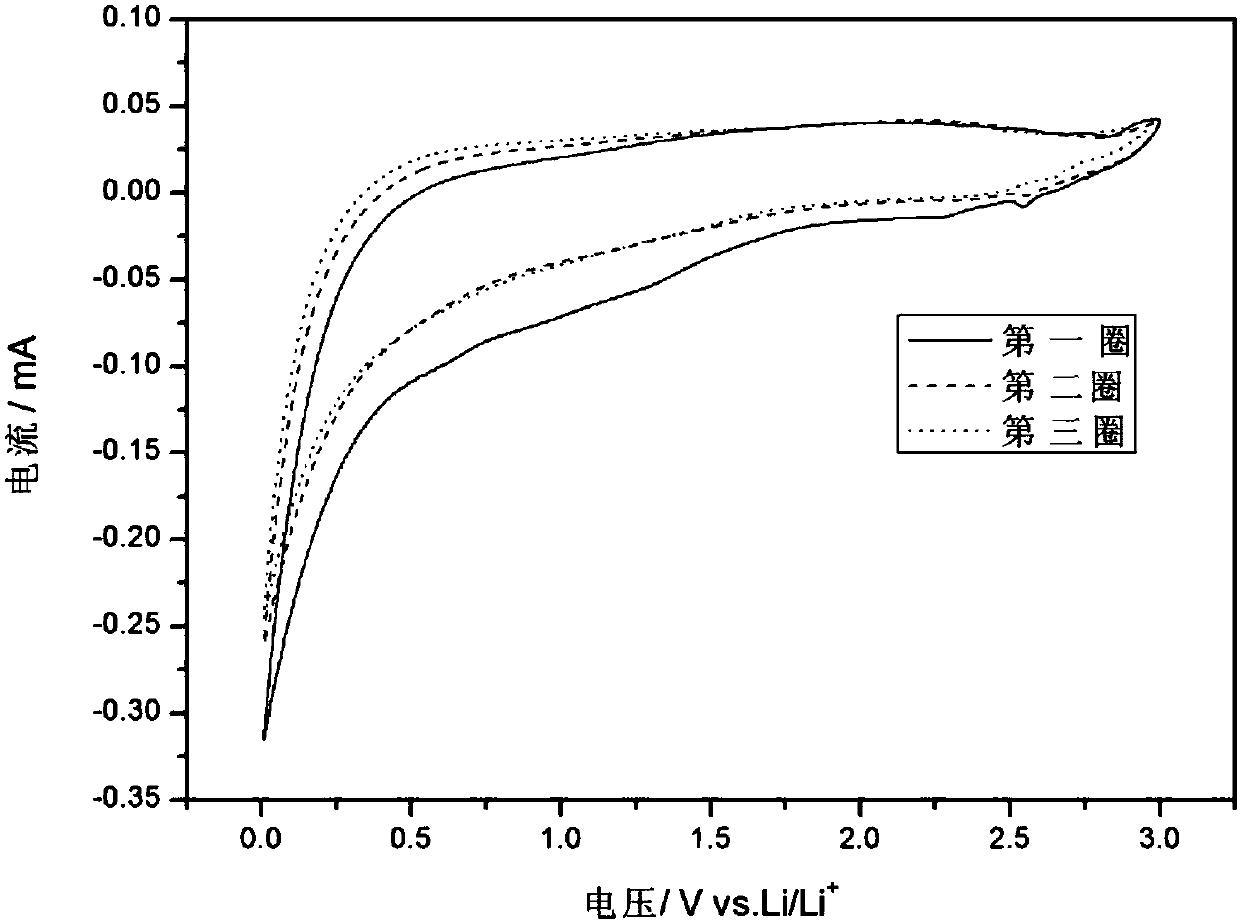

[0027] Such as image 3 As shown, the carbon microspheres co-doped with iodine and nitrogen are used as the cyclic voltammetry curves of the first three cycles of the negative electrode of the lithium-io...

Embodiment 3

[0029] In a nitrogen-protected glove box, add 1 gram of cetyltrimethylammonium bromide, 2 grams of analytically pure hydroiodic acid and 28 ml of acetonitrile to 4 ml of xylene in sequence, stir for 30 minutes, and put the mixture into a volume In a 45ml stainless steel reaction kettle, seal it; then place the reaction kettle in a crucible boiler, heat it at 450°C for 48 hours, then wait for the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed 6 times successively with absolute ethanol, dilute hydrochloric acid and distilled water, filtered, and then vacuum-dried at 100°C and 0.1MPa vacuum for 6 hours to obtain iodine-nitrogen co-doped carbon microparticles with high volume specific capacitance. ball.

[0030] Such as Figure 4 As shown, it can be seen that the dispersion of carbon microspheres is good, and the surface of the microspheres is smooth, the diameter is between 2 microns and 6 microns, and the spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com