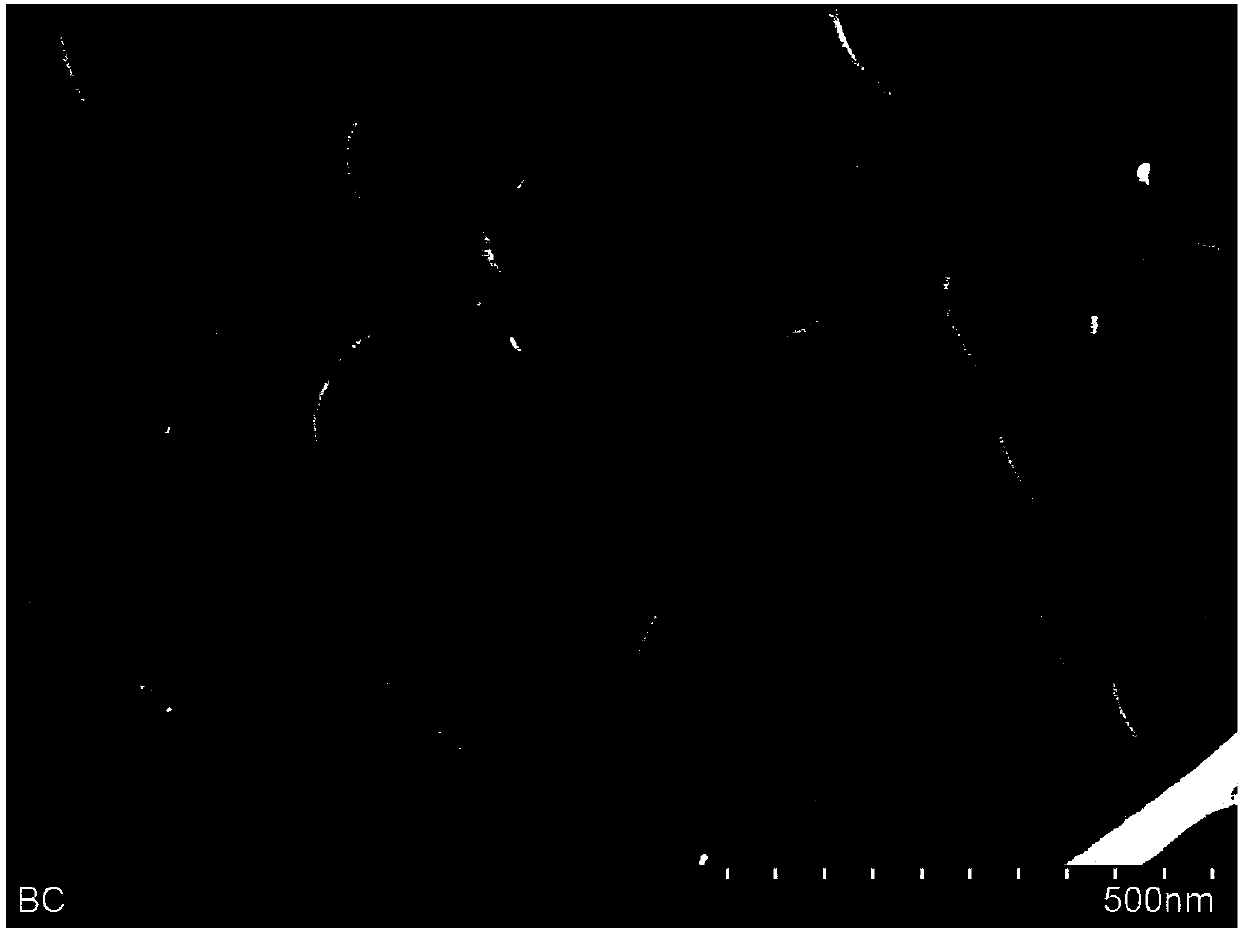

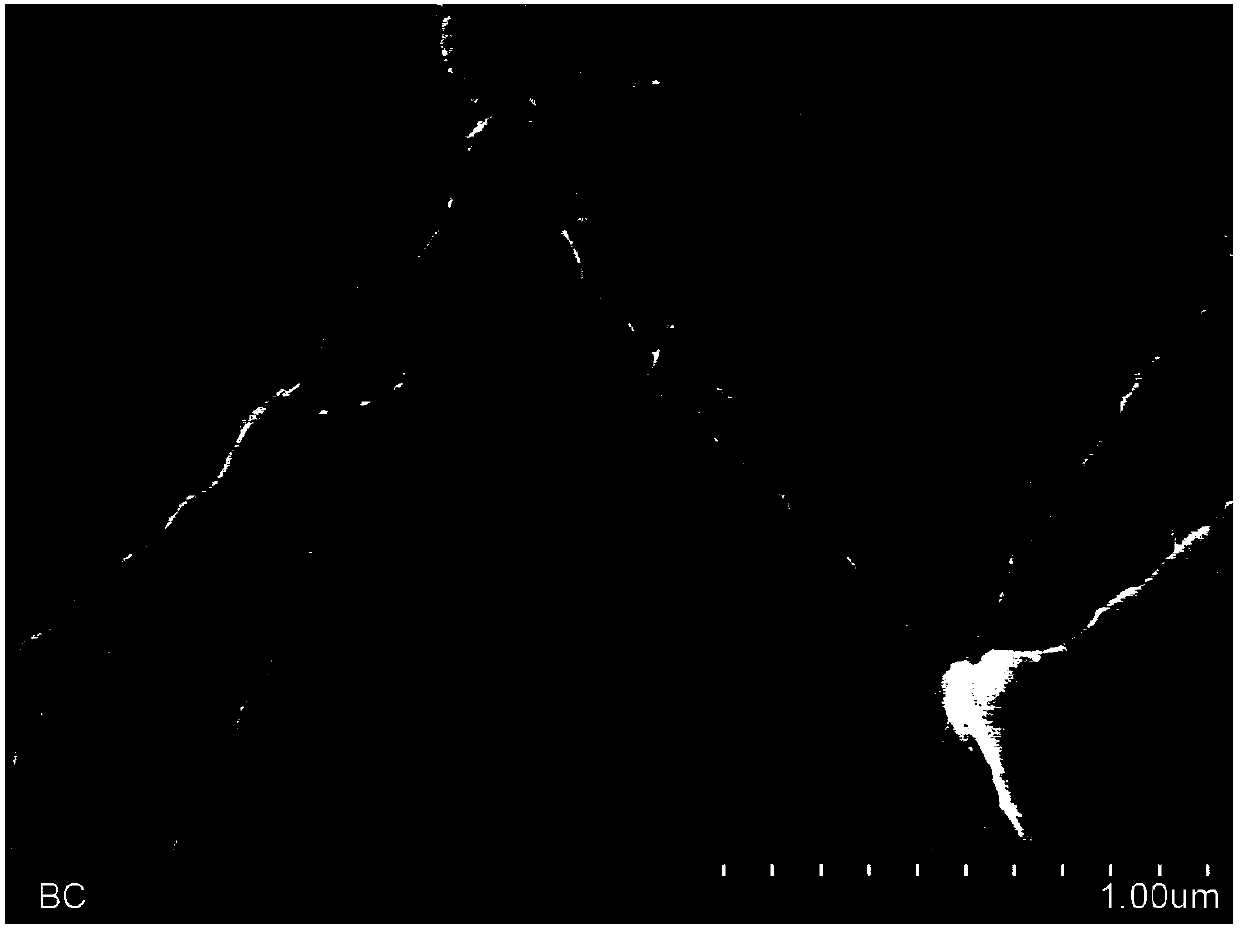

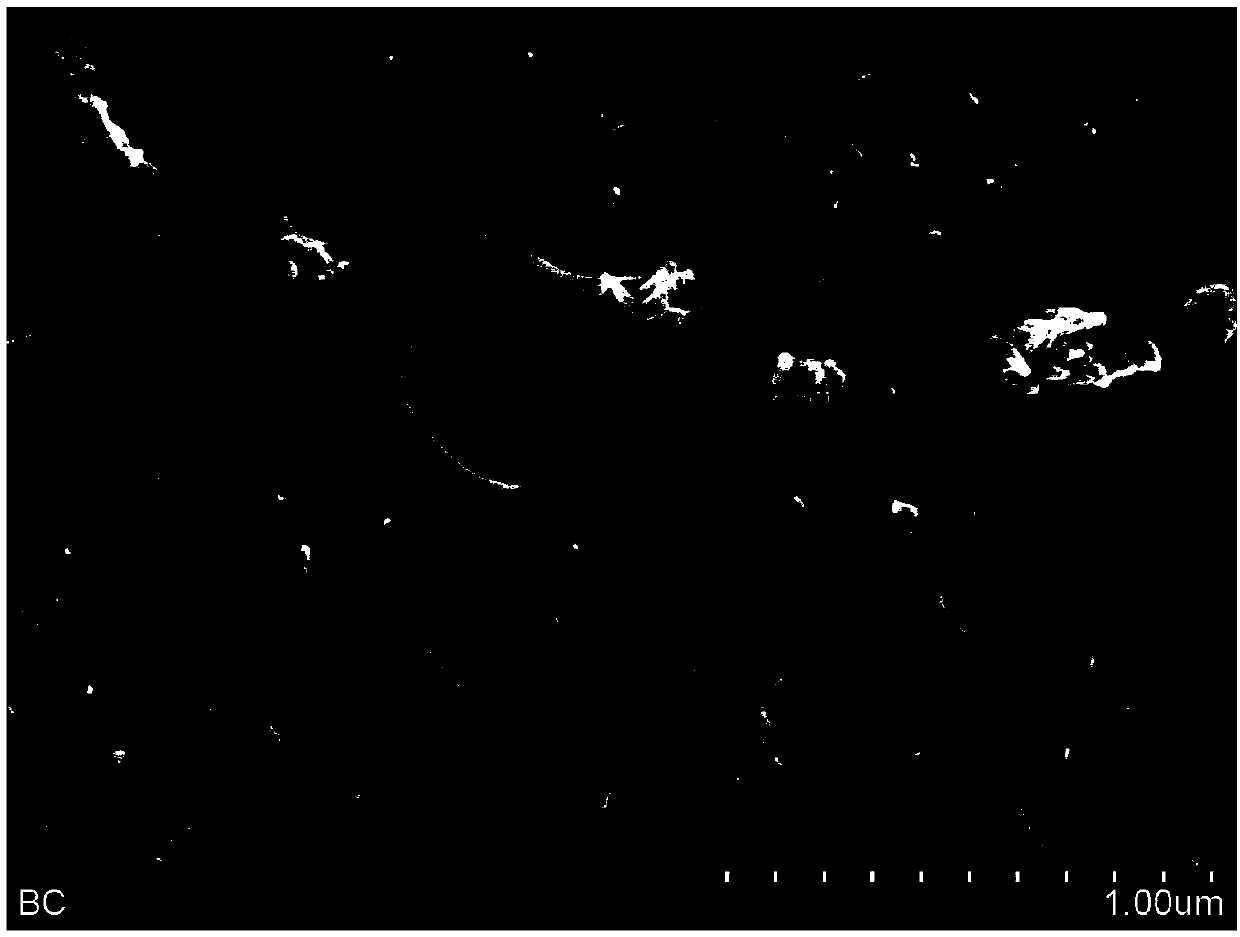

Bacterial cellulose membrane composite material having nanometer cobweb structure and preparation method thereof

A bacterial cellulose membrane and bacterial cellulose technology are applied in the field of bacterial cellulose membrane composite materials and their preparation, which can solve the problems of complex preparation process of nanofibers, inability of nanofibers to effectively block particles that can enter the lungs and harmful bacteria, and the like. Good promotion value, air permeability, light weight, high strength, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of preparation method of the bacterial cellulose film composite material with nano spider web structure, the steps are as follows:

[0046] (1) Sterilize the non-woven fabric: cut the non-woven fabric with a hydrophilic surface into the required size, and spread it in the culture container after high-pressure steam sterilization, wherein the non-woven fabric with a hydrophilic surface is made of The non-woven fabric is made by surface hydrophilic treatment. The surface hydrophilic treatment refers to the grafting of negatively charged hydrophilic groups on the surface of the non-woven fabric made of PP material with an average diameter of 30 μm. The surface of the non-woven fabric is hydrophilic. The thickness of the cloth is 0.1mm, and the surface density is 20g / m 2 , the surface static water contact angle is 70°;

[0047] (2) Preparation of fermentation broth: by mass percentage, the unit is wt%. Each component and its content in the fermentation broth are as ...

Embodiment 2

[0055] A kind of preparation method of the bacterial cellulose film composite material with nano spider web structure, the steps are as follows:

[0056] (1) Sterilize the non-woven fabric: cut the non-woven fabric with a hydrophilic surface into the required size, and spread it in the culture container after being sterilized by ultraviolet radiation. Among them, the non-woven fabric with a hydrophilic surface It is made of non-woven fabric through surface hydrophilic treatment. Surface hydrophilic treatment refers to grafting negatively charged hydrophilic groups on the surface of non-woven fabric made of PET material with an average diameter of 50 μm. The surface is hydrophilic. The thickness of the non-woven fabric is 0.2mm, and the surface density is 30g / m 2 , the surface static water contact angle is 69°;

[0057] (2) Preparation of fermentation broth: by mass percentage, the unit is wt%. In the fermentation broth, each component and its content are as follows: 3 sucrose...

Embodiment 3

[0065] A kind of preparation method of the bacterial cellulose film composite material with nano spider web structure, the steps are as follows:

[0066] (1) Sterilize the non-woven fabric: cut the non-woven fabric with a hydrophilic surface into the required size, and spread it in the culture container after being sterilized with ethylene oxide. The non-woven fabric with a hydrophilic surface is It is made of non-woven fabric through surface hydrophilic treatment. Surface hydrophilic treatment refers to grafting negatively charged hydrophilic groups on the surface of non-woven fabric made of PA material with an average diameter of 40 μm. The thickness of the woven fabric is 0.3mm, and the surface density is 18g / m 2 , the surface static water contact angle is 62°;

[0067] (2) Preparation of fermentation broth: by mass percentage, the unit is wt%. Each component and its content in the fermentation broth are as follows: glucose 2, peptone 0.5, yeast extract 0.08, citric acid 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com