Full-silicon MEMS wafer-level vacuum packaging method based on anode bonding

A technology of anodic bonding and vacuum packaging, which is applied in the fields of crafts for producing decorative surface effects, decorative arts, microstructure devices, etc., and can solve problems such as large parasitic capacitance of MEMS structures, high processing costs, and low tape-out yields , to achieve the effect of improving temperature stability, small parasitic capacitance, and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

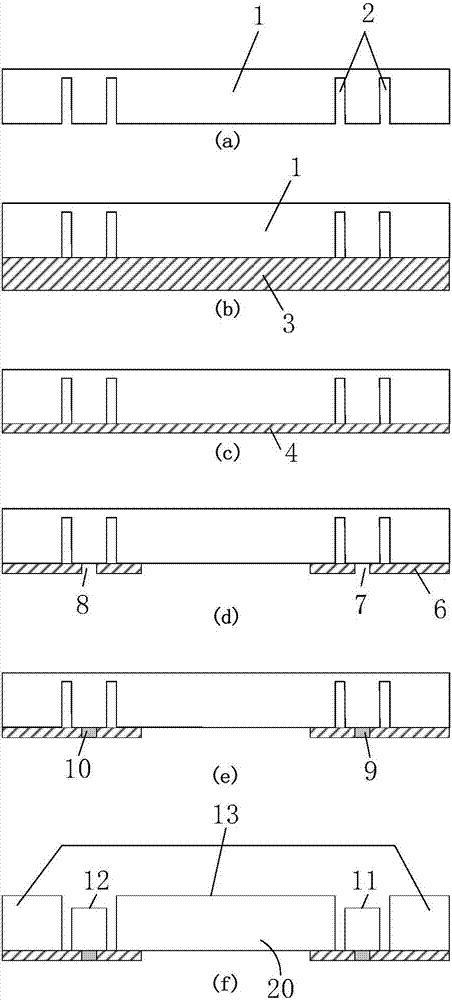

[0050] Such as figure 1 As shown, wherein the processing method of the silicon cover plate starts with the ICP etching (inductively coupled plasma etching) of the low-resistance silicon wafer 1 of the cover plate, and forms the electrode isolation groove 2, as figure 1 (a) shown.

[0051] After ICP etching, the cover plate low-resistance silicon wafer 1 and the cover plate borosilicate glass plate 3 are activated by oxygen plasma for bonding, such as figure 1 (b) shown.

[0052] After bonding, the bonded sheets 1 and 3 are etched in hydrofluoric acid, and the thickness of 3 is reduced to 10-50 microns to form a thin glass layer 4 for the cover plate, such as figure 1 (c) shown.

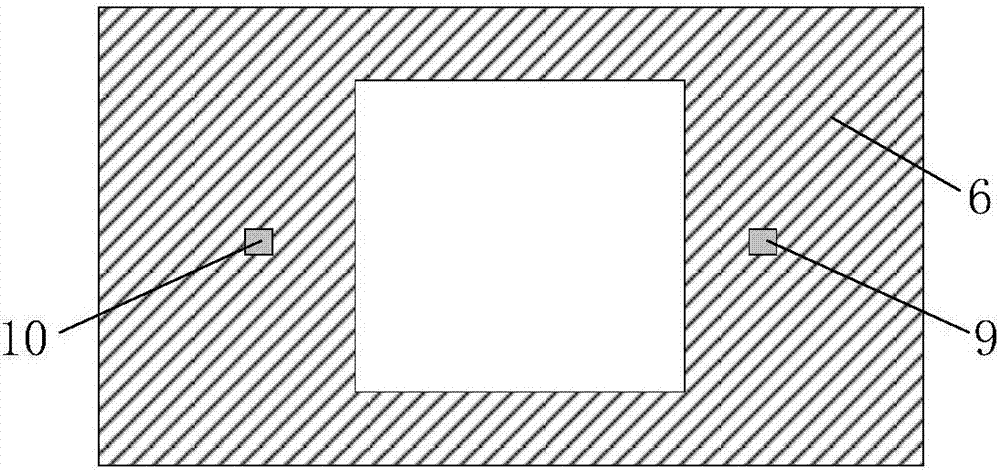

[0053] After photolithography, hydrofluoric acid is used to corrode the thin glass layer 4 of the cover plate to form electrode contact holes 7, 8 and a glass sealing ring 6 on the cover plate.

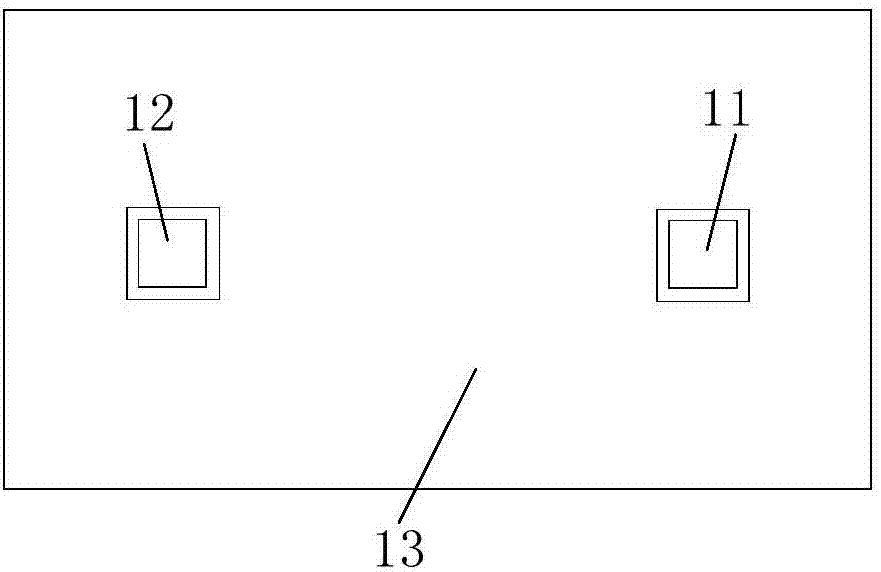

[0054] Through electroplating, evaporation, magnetron sputtering and other processes combined with sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com