Environment-friendly formaldehyde removal material and preparation method thereof

An environmentally friendly material and formaldehyde technology, applied in the field of pollution control, can solve the problems of low utilization efficiency of visible light, catalyst deactivation, high price, etc., and achieve the effect of enhanced formaldehyde removal effect, good performance stability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

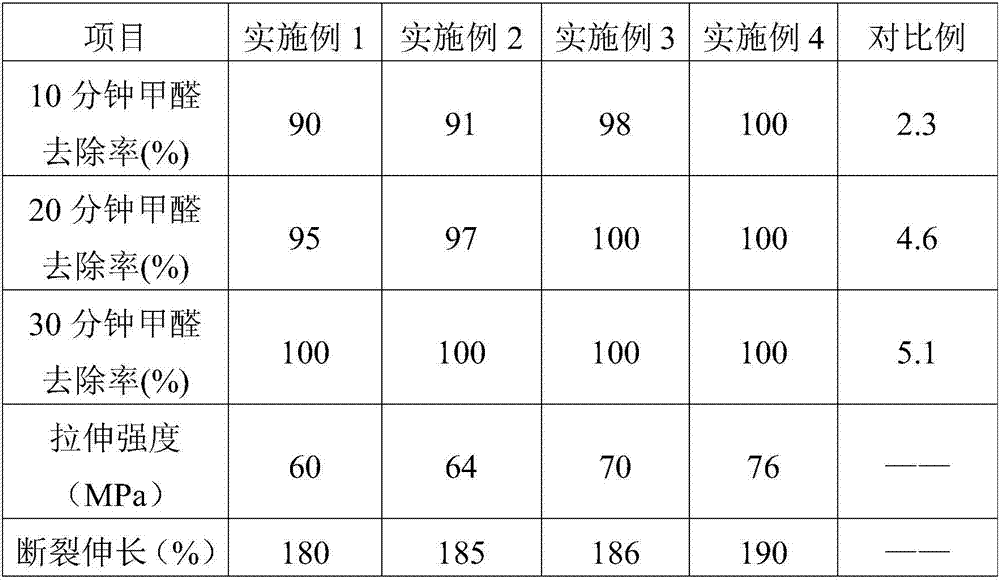

Examples

Embodiment 1

[0026] A preparation method for formaldehyde-removing environmental protection material, comprising the steps of:

[0027] 1) Preparation of intermediate: 10 g of 4-chloromethylstyrene was dissolved in 50 g of ethanol, and 10 g of aminopropanol ascorbyl phosphate and 2 g of hydroquinone were added thereto, stirred at room temperature for 4 hours, then at 40 Rotary evaporation at ℃ to remove the solvent, then wash the product with a mixed solvent for 5 times, and finally remove the solvent by rotary evaporation at 30 °C; the mixed solvent is a mixture of diethyl ether and dichloromethane in a mass ratio of 3:7;

[0028] 2) Preparation of copolymer material: Dissolve 6 g of the intermediate prepared in step 1) in 15 g of dimethyl sulfoxide, and then add 3 g of 1,3-divinyl-2-imidazolidinone and azobis 0.09g of isobutyronitrile, stirred and reacted at 50°C for 1 hour, and then cast the product to form a film;

[0029] 3) Ion exchange: soak the copolymer material prepared in step ...

Embodiment 2

[0032] A preparation method for formaldehyde-removing environmental protection material, comprising the steps of:

[0033] 1) Preparation of intermediate: 4-chloromethylstyrene 10g was dissolved in isopropanol 70g, and aminopropanol ascorbyl phosphate 11g and quinone tetrachloride 3g were added thereto, stirred at room temperature for 5 hours, and then Remove the solvent by rotary evaporation at 43°C, then wash the product with a mixed solvent for 6 times, and finally remove the solvent by rotary evaporation at 33°C; the mixed solvent is a mixture of diethyl ether and dichloromethane in a mass ratio of 3:7;

[0034] 2) Preparation of copolymer material: Dissolve 7.3 g of the intermediate prepared in step 1) in 20 g of N-methylpyrrolidone, and then add 4 g of 1,3-divinyl-2-imidazolidinone and even Azodiisoheptanonitrile 0.12g, stirred and reacted at 55°C for 1.2 hours, and then cast the product to form a film;

[0035] 3) Ion exchange: soak the copolymer material prepared in s...

Embodiment 3

[0038] A preparation method for formaldehyde-removing environmental protection material, comprising the steps of:

[0039] 1) Preparation of intermediate: Dissolve 10 g of 4-chloromethylstyrene in 80 g of ethylene glycol, add 12 g of aminopropanol ascorbyl phosphate and 4 g of 1,4-naphthoquinone, and stir at room temperature for 5.5 hours , then remove the solvent by rotary evaporation at 47°C, wash the product with a mixed solvent for 7 times, and finally remove the solvent by rotary evaporation at 36°C; the mixed solvent is a mixture of diethyl ether and dichloromethane in a mass ratio of 3:7;

[0040] 2) Preparation of copolymer material: Dissolve 8 g of the intermediate prepared in step 1) in 26 g of N,N-dimethylformamide, and then add 1,3-divinyl-2-imidazolinone to it 5.5g and 0.14g of dicumyl peroxide, stirred and reacted at 60°C for 1.8 hours, and then cast the product into a film;

[0041] 3) Ion exchange: soak the copolymer material prepared in step 2) in a solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com