Visible light catalyst containing copper oxide and application thereof

A copper oxide, visible light technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of high energy consumption, difficult catalyst recovery, and toxic solvents and other problems, to achieve the effects of high yield, excellent photocatalytic efficiency, and easy separation and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of this visible light catalyst comprises the steps:

[0037] (1) Using salt compounds containing copper and the above-mentioned A and / or B elements as raw materials, such as using copper-containing chlorides, nitrates, etc., and using chlorides and nitric acid containing the above-mentioned A metal elements and B metal elements Salt and the like are used as raw materials, and the salts of A and B can be selected from one of the two, or can be selected at the same time, and the copper-containing metal oxide is prepared by co-precipitation method, hydrothermal method, low-temperature combustion method or sol-gel method;

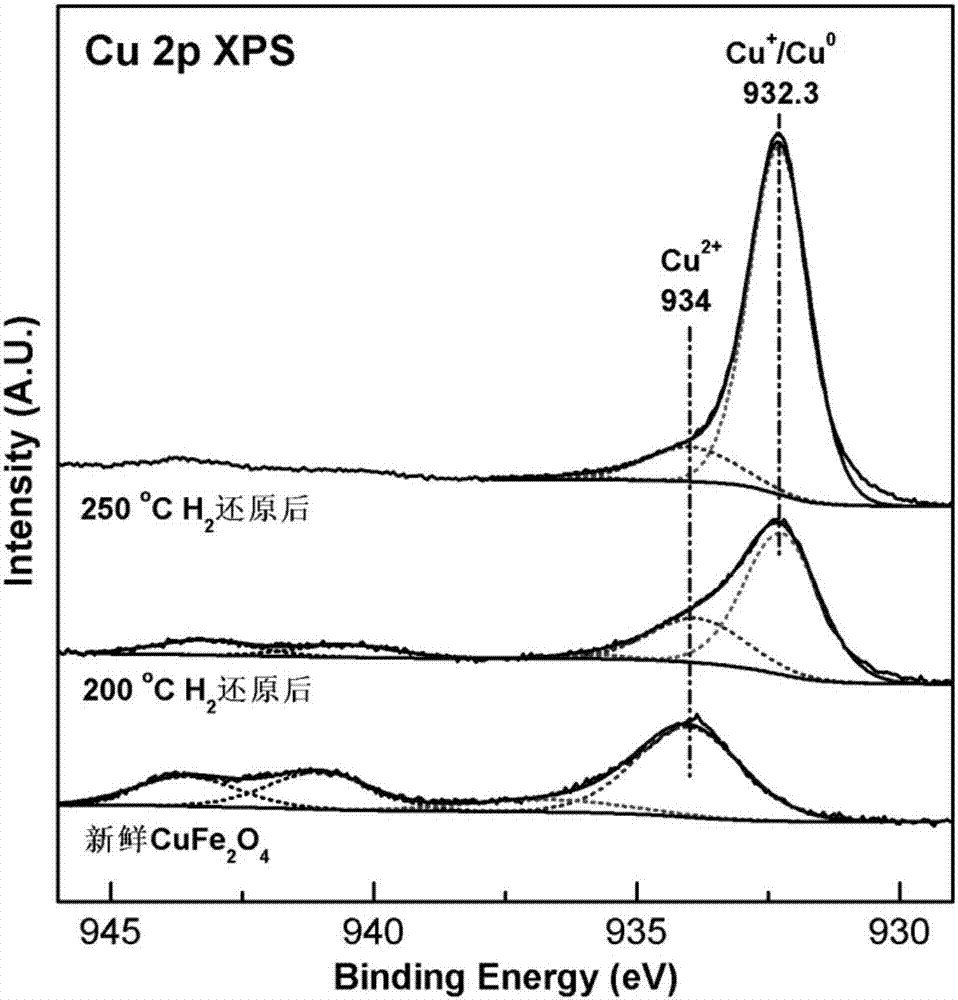

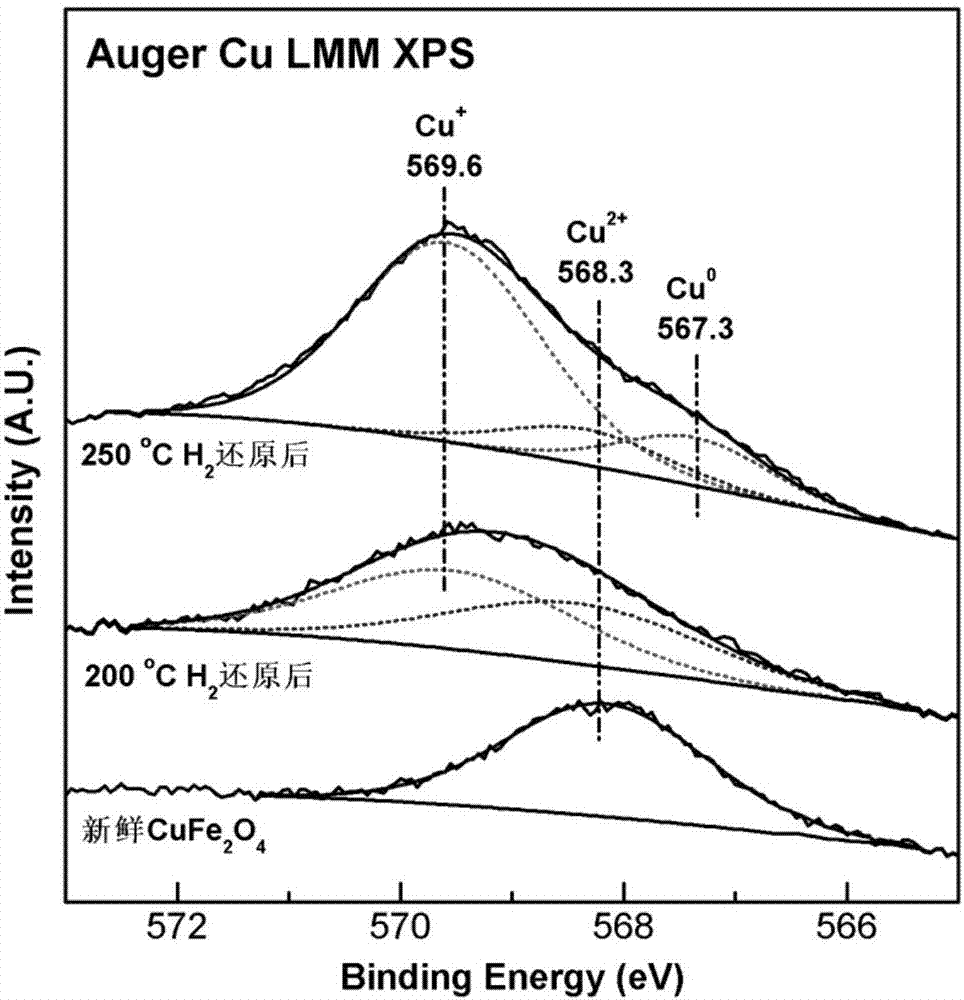

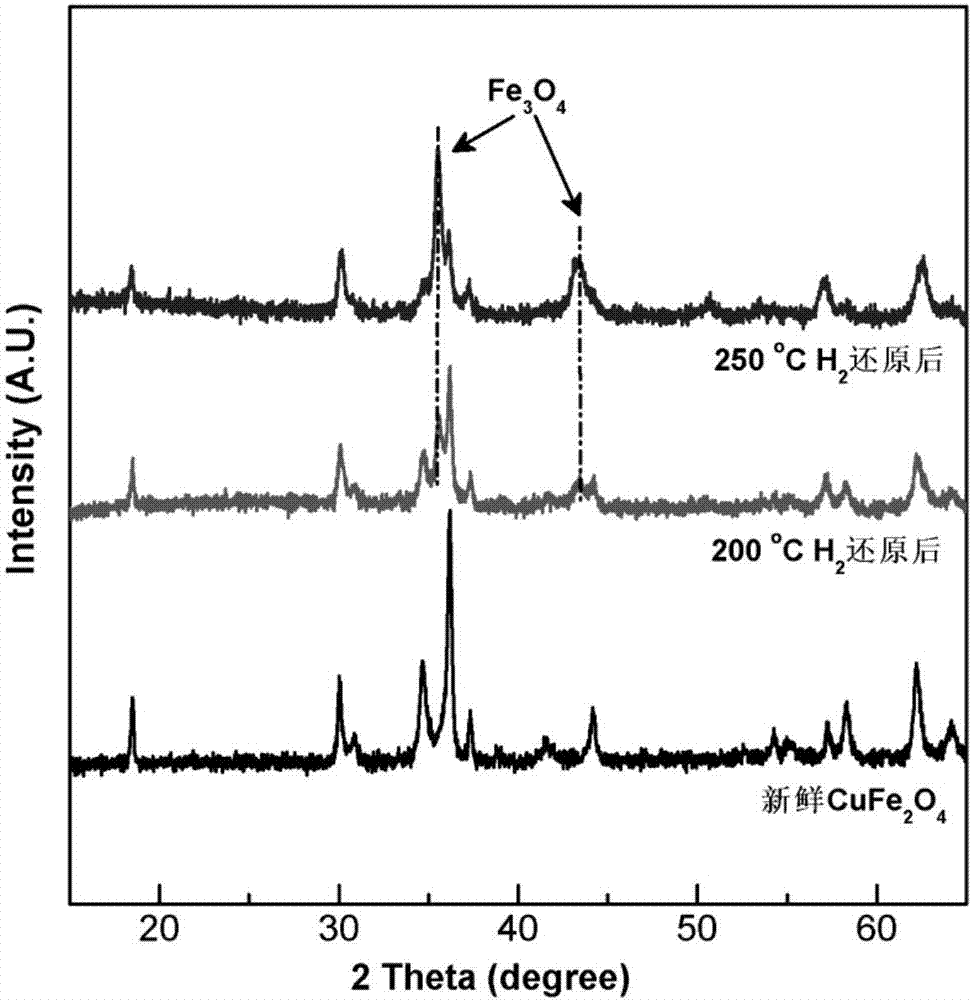

[0038] (2) Place the copper-containing metal oxide described in step (1) under a hydrogen atmosphere, and activate it at 150-300° C. for 0.5-5 hours to obtain the A x B y Cu z o n . After hydrogen reduction, the low-valence species in the variable-valence metal elements increase, which can improve the catalytic efficiency. Var...

Embodiment 1

[0045] Preparation of CuAl by Co-precipitation 2 o 4 For visible light catalyzed phenylacetylene coupling reaction. Weigh 4.83g of copper nitrate and 15.01g of aluminum nitrate, dissolve them in 60mL of deionized water and place them in a 100mL constant pressure dropping funnel, weigh 6.5g of sodium hydroxide and dissolve them in 60mL of deionized water and place them in another 100mL constant pressure dropping funnel Measure 60mL of deionized water into a 250mL three-necked round-bottomed flask and place it in a 50°C water bath for electromagnetic stirring. At the same time, add the mixed salt solution and alkali solution dropwise into the three-necked flask, and control the dropping speed so that the pH of the precipitation slurry remains constant at ~11. After the dropwise addition, continue to stir for 3 hours, after cooling, filter with suction, wash with a large amount of deionized water until the pH of the filtrate is ~7, dry the filter cake at 110°C overnight, grind i...

Embodiment 2

[0048] Preparation of CuCr by Co-precipitation 2 o 4 For visible light catalyzed phenylacetylene coupling reaction. Weigh 4.83g copper nitrate and 16.0g chromium nitrate, dissolve them in 60mL deionized water and place them in a 100mL constant pressure dropping funnel, weigh 6.5g sodium hydroxide and dissolve them in 60mL deionized water and place them in another 100mL constant pressure dropping funnel Measure 60mL of deionized water into a 250mL three-necked round-bottomed flask and place it in a 50°C water bath for electromagnetic stirring. At the same time, add the mixed salt solution and alkali solution dropwise into the three-necked flask, and control the dropping speed so that the pH of the precipitation slurry remains constant at ~11. After the dropwise addition, continue to stir for 3 hours, after cooling, filter with suction, wash with a large amount of deionized water until the pH of the filtrate is ~7, dry the filter cake at 110°C overnight, grind it and roast it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com