Preparation method of nitrogen-sulfur co-doped carbon quantum dot

A technology of carbon quantum dots and co-doping, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanocarbon, etc., can solve difficult production and application promotion, expensive raw materials, cumbersome preparation process, etc. problems, to achieve the effect of easy preparation and industrial production, great application potential, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

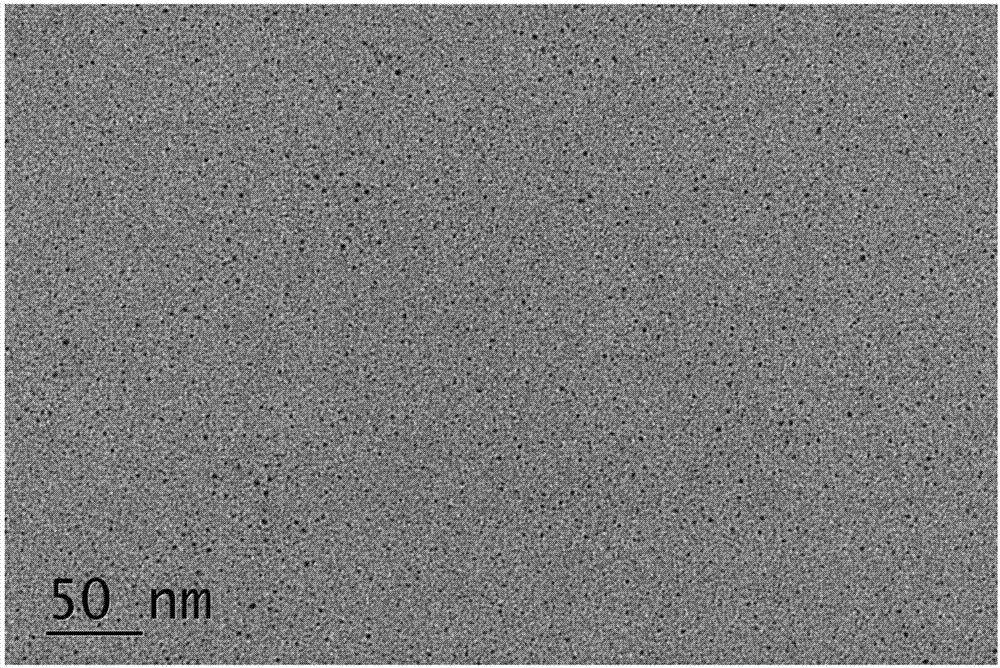

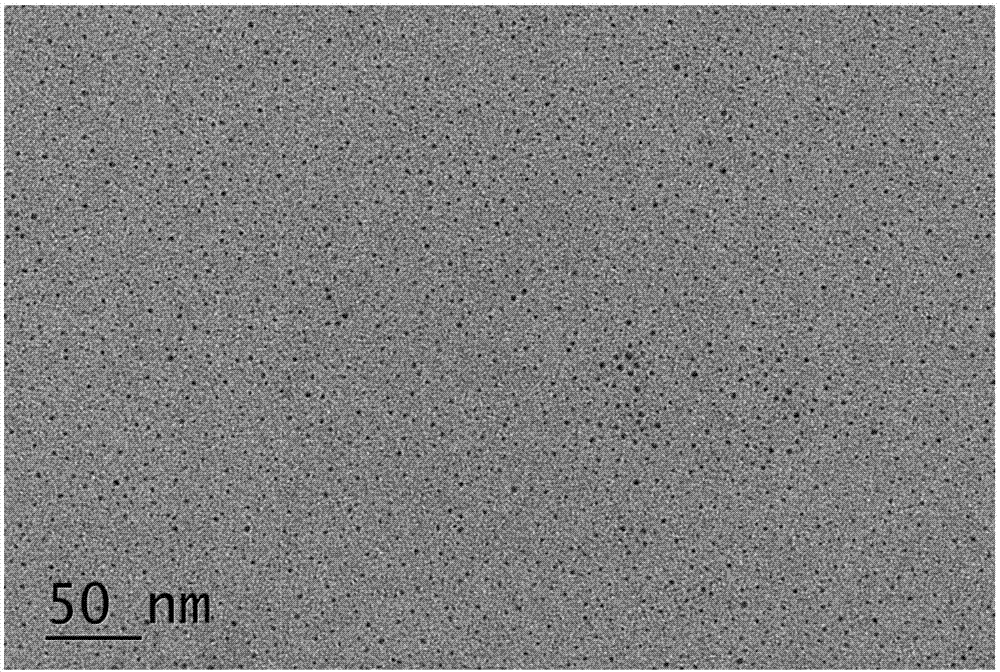

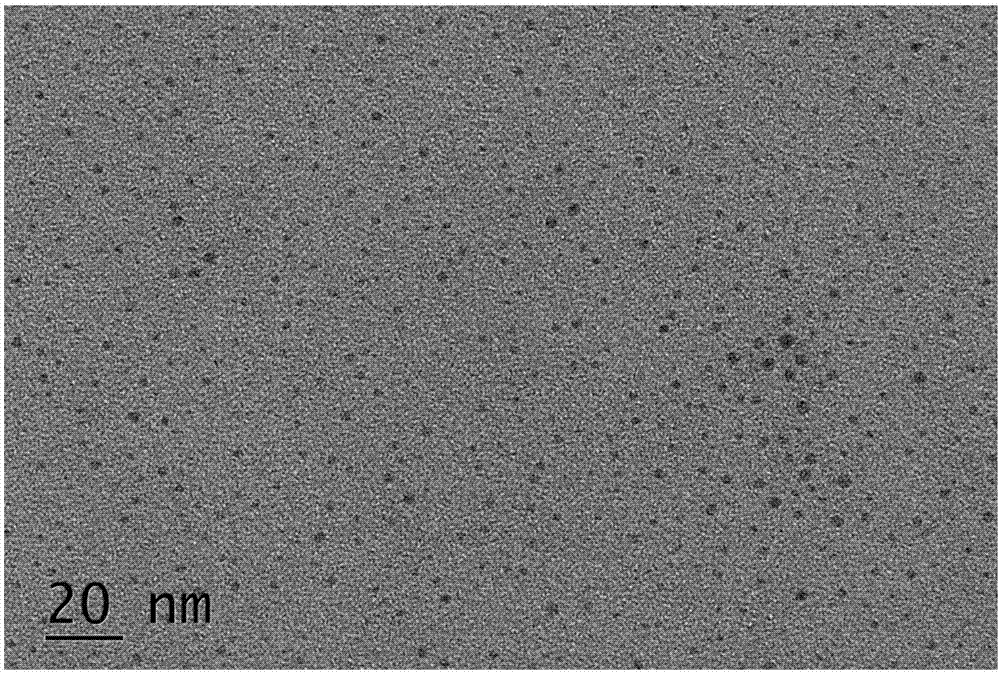

[0019] Peel the durian to obtain the durian pulp, weigh 30 grams of durian pulp and 50 ml of ultra-pure water into the hydrothermal kettle, and heat it in an oven at 180°C for 12 hours. After the hydrothermal reaction is over, take out the hydrothermal kettle and let it cool naturally to room temperature, and then pour out the reaction liquid in the hydrothermal reaction kettle; centrifuge at a high speed of 10,000 rpm for 15 minutes, and filter and purify using 0.45 micron and 0.22 micron mixed cellulose ester (water system) microporous membranes successively. A solution of carbon quantum dots was obtained. The carbon quantum dot solution was sampled and placed in a refrigerator at 4°C for low temperature storage. After one year of observation, it was found that the carbon quantum dot solution did not deteriorate, indicating that the obtained carbon quantum dots had excellent water solubility and could be dispersed stably and evenly in water.

[0020] Then pre-freeze the carb...

Embodiment 2

[0023] Peel the durian to obtain the durian pulp, weigh 30 grams of durian pulp and 50 ml of ultra-pure water into the hydrothermal kettle, and heat it in an oven at 160°C for 24 hours. After the hydrothermal reaction is over, take out the hydrothermal kettle and let it cool naturally to room temperature, and then pour out the reaction liquid in the hydrothermal reaction kettle; after 30 minutes of high-speed centrifugation at a speed of 8000 rpm, filter and purify using 0.45 micron and 0.22 micron mixed cellulose resin (water system) microporous membranes successively, A solution of carbon quantum dots was obtained. The carbon quantum dot solution was sampled and placed in a refrigerator at 4°C for low temperature storage. After one year of observation, it was found that the carbon quantum dot solution did not deteriorate, indicating that the obtained carbon quantum dots had excellent water solubility and could be dispersed stably and evenly in water.

[0024] Then pre-freeze...

Embodiment 3

[0027]Peel the durian to obtain the durian pulp, weigh 25 grams of durian pulp and 50 ml of ultra-pure water into the hydrothermal kettle, and heat it in an oven at 210°C for 8 hours. After the hydrothermal reaction is over, take out the hydrothermal kettle and let it cool naturally to room temperature, then pour out the reaction liquid in the hydrothermal reaction kettle; centrifuge at a speed of 10,000 rpm for 15 minutes, and then use 0.45 micron and 0.22 micron mixed cellulose resin (water system) microporous membrane filter for filtration Purify to obtain a carbon quantum dot solution. The carbon quantum dot solution was sampled and placed in a refrigerator at 4°C for low temperature storage. After one year of observation, it was found that the carbon quantum dot solution did not deteriorate, indicating that the obtained carbon quantum dots had excellent water solubility and could be dispersed stably and evenly in water.

[0028] Then pre-freeze the carbon quantum dot solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com