A kind of plastic preservative film used for kiwi fruit packaging and preparation method thereof

A technology for kiwifruit and fresh-keeping film, which is applied to the field of food preservation materials, can solve the problems of perishable and deteriorated, high carbon dioxide concentration, and short shelf life of kiwifruit, and achieves the effects of maintaining a low-oxygen environment, improving the permeability ratio, and prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

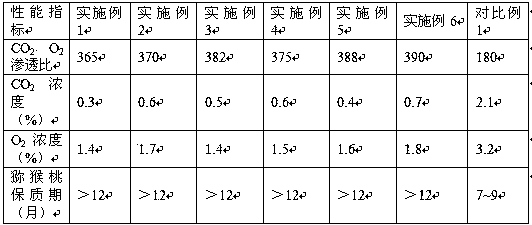

Embodiment 1

[0034] (1) The specific process of the preparation of the composite emulsion is:

[0035] First use ethanol solution to wash polymethyl methacrylate microspheres, dry them, put them into a mixture of hydrogen peroxide and sulfuric acid, heat them for a period of time, wash them with distilled water after natural cooling, and then add them to polyvinylidene chloride emulsion , magnetic stirring until a uniform and stable composite emulsion is formed;

[0036] In the composite emulsion, the total mass parts of each component is calculated as 100 parts, including: 15 parts of polymethyl methacrylate microspheres, 28 parts of polyvinylidene chloride, 1 part of emulsifier, and 56 parts of water;

[0037] In the mixture of hydrogen peroxide and sulfuric acid, the volume ratio of hydrogen peroxide and sulfuric acid is 3:7; the heating temperature is 85°C, and the treatment time is 60 minutes; the emulsifier is calcium dodecylbenzenesulfonate;

[0038] (2) The specific process of coa...

Embodiment 2

[0045] (1) The specific process of the preparation of the composite emulsion is:

[0046] First use ethanol solution to wash polymethyl methacrylate microspheres, dry them, put them into a mixture of hydrogen peroxide and sulfuric acid, heat them for a period of time, wash them with distilled water after natural cooling, and then add them to polyvinylidene chloride emulsion , magnetic stirring until a uniform and stable composite emulsion is formed;

[0047] In the composite emulsion, the total parts by mass of each component are based on 100 parts, including: 10 parts of polymethyl methacrylate microspheres, 25 parts of polyvinylidene chloride, 1 part of emulsifier, and 64 parts of water;

[0048] In the mixture of hydrogen peroxide and sulfuric acid, the volume ratio of hydrogen peroxide and sulfuric acid is 3:7; the heating temperature is 80°C, and the treatment time is 70 minutes; the emulsifier is monoglyceride laurate;

[0049] (2) The specific process of coating the co...

Embodiment 3

[0056] (1) The specific process of the preparation of the composite emulsion is:

[0057] First use ethanol solution to wash polymethyl methacrylate microspheres, dry them, put them into a mixture of hydrogen peroxide and sulfuric acid, heat them for a period of time, wash them with distilled water after natural cooling, and then add them to polyvinylidene chloride emulsion , magnetic stirring until a uniform and stable composite emulsion is formed;

[0058] In the composite emulsion, the total mass parts of each component is calculated as 100 parts, including: 20 parts of polymethyl methacrylate microspheres, 30 parts of polyvinylidene chloride, 2 parts of emulsifier, and 48 parts of water;

[0059] In the mixture of hydrogen peroxide and sulfuric acid, the volume ratio of hydrogen peroxide and sulfuric acid is 4:7; the heating temperature is 90°C, and the treatment time is 50 minutes; the emulsifier is monopalmitate;

[0060] (2) The specific process of coating the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com