Hydroxyapatite-based bone tissue engineering bracket and powder 3D printing method thereof

A technology of tissue engineering scaffold and hydroxyapatite, which is applied in the field of biomedical materials, can solve the problems of affecting printing efficiency and printing accuracy, low scaffold strength, slow molding and curing, etc., and achieve fast printing speed, improved mechanical properties, and good flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

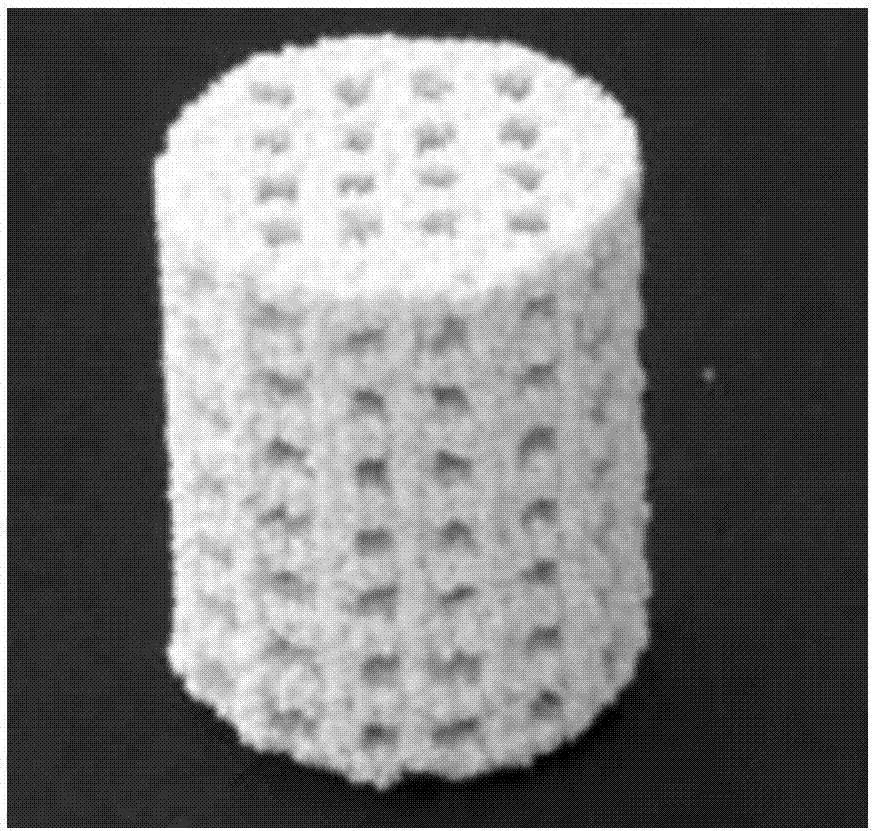

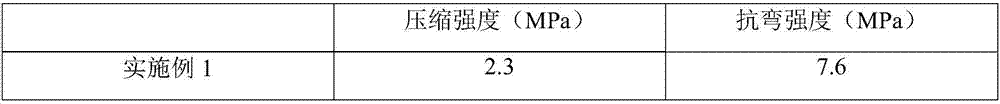

Examples

Embodiment 1

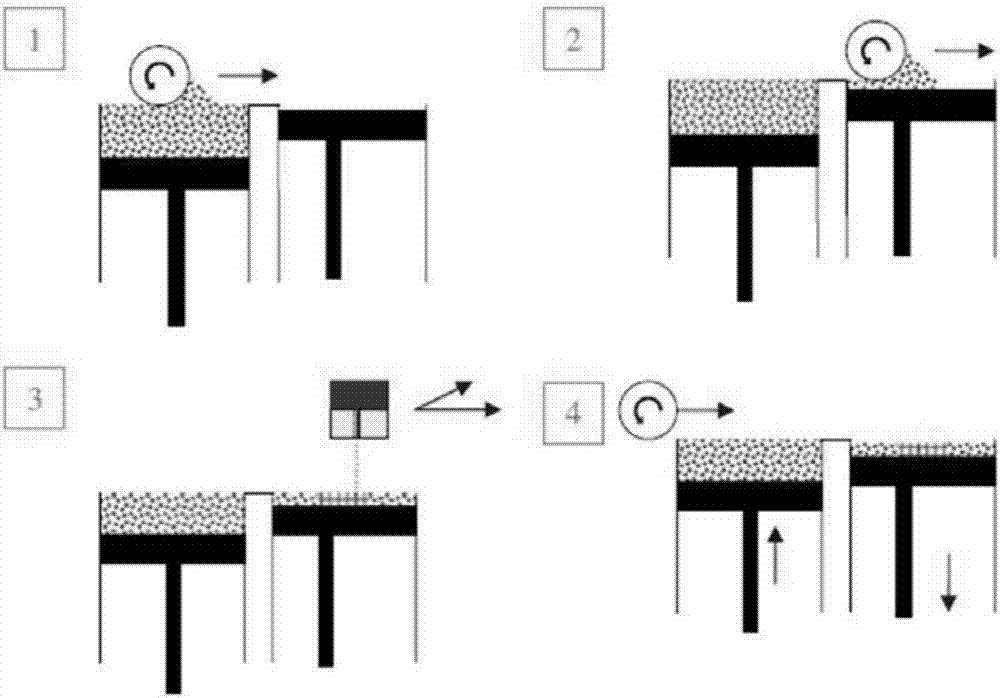

[0035] The powder 3D printing method of the hydroxyapatite-based bone tissue engineering scaffold has the following steps:

[0036] (1) Using CT three-dimensional imaging technology to reconstruct the health status map of the defect, combined with the defect bone state map waiting to be implanted, separate the bone morphology map to be implanted, and form a DICOM format map; convert it into STL for 3D printing through software File, further process the STL format file according to the required porosity and connectivity requirements; import the modified STL file into the 3D printer.

[0037] (2) Take a certain mass of Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 and gelatin, were prepared as aqueous solutions; the gelatin solution was added to Ca(NO 3 ) 2 A mixed solution is formed in the solution; the pH value is adjusted to 10 with ammonia water; (NH 4 )2 HPO 4 The solution was dropped into the mixed solution for in-situ chemical co-precipitation reaction to obtain hydroxyapatite / ge...

Embodiment 2

[0040] (1) Using CT three-dimensional imaging technology to reconstruct the health status map of the defect, combined with the defect bone state map waiting to be implanted, separate the bone morphology map to be implanted, and form a DICOM format map; convert it into STL for 3D printing through software File, further process the STL format file according to the required porosity and connectivity requirements; import the modified STL file into the 3D printer.

[0041] (2) Take a certain mass of Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 and chitosan, respectively formulated into aqueous solutions; the chitosan solution was added to the Ca(NO 3 ) 2 A mixed solution is formed in the solution; the pH value is adjusted to 10 with ammonia water; (NH 4 ) 2 HPO 4 Drop the solution into the mixed solution for in-situ chemical co-precipitation reaction to obtain hydroxyapatite / chitosan composite slurry; after the reaction, obtain hydroxyapatite / chitosan composite powder by spray drying meth...

Embodiment 3

[0044] (1) Using CT three-dimensional imaging technology to reconstruct the health status map of the defect, combined with the defect bone state map waiting to be implanted, separate the bone morphology map to be implanted, and form a DICOM format map; convert it into STL for 3D printing through software File, further process the STL format file according to the required porosity and connectivity requirements; import the modified STL file into the 3D printer.

[0045] (2) According to Ca / P atomic ratio=1.67, inorganic / organic phase ratio 60 / 40, gelatin / chitosan ratio 1 / 1, weigh a certain amount of Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 , gelatin and chitosan were formulated into aqueous solutions respectively; the chitosan solution was added to Ca(NO 3 ) 2 The solution was mixed solution A, and the gelatin solution was added to (NH 4 ) 2 HPO 4 A mixed solution B is formed in the solution; the pH value is adjusted to 10 with ammonia water; the mixed solution B is added dropwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com