Preparation method of phenyl boryl modified covalent affine magnetic solid phase extractant

A solid-phase extractant and magnetic technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of many reaction steps, low yield, unstable phenylboron group, etc., to simplify the reaction. process, improvement of synthesis conditions, and the effect of simplifying the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

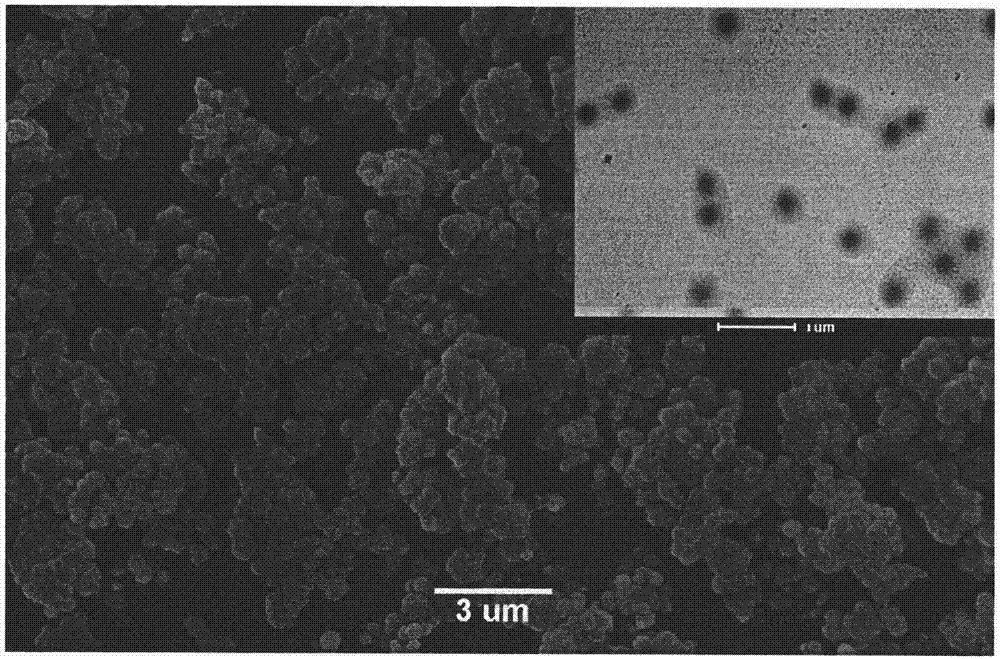

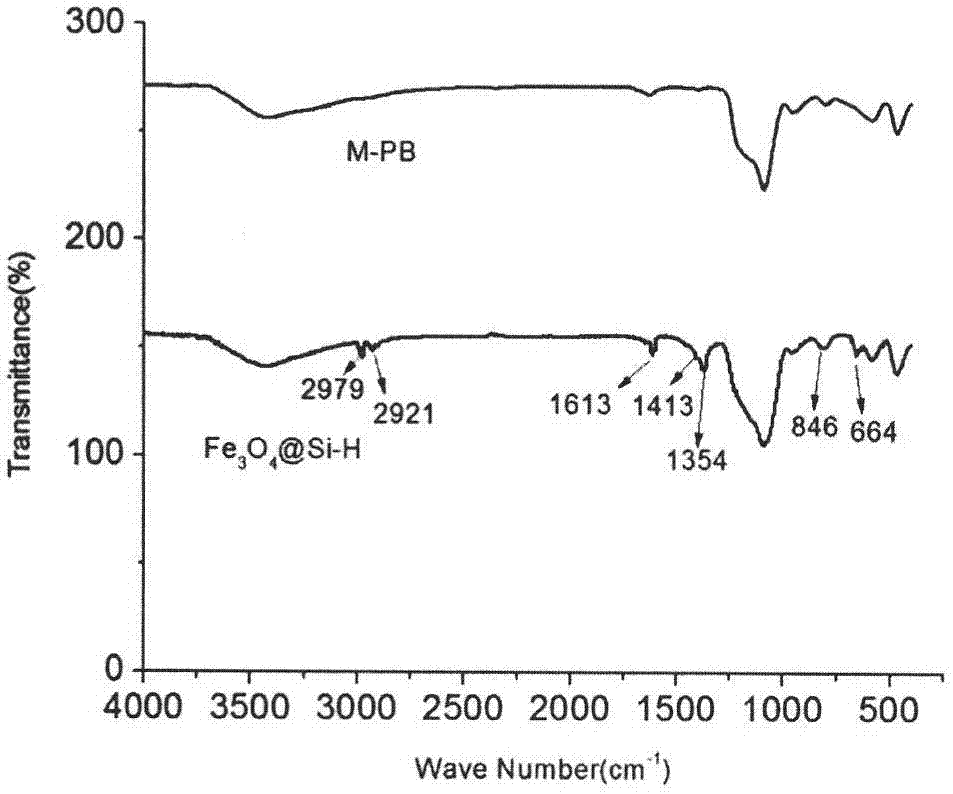

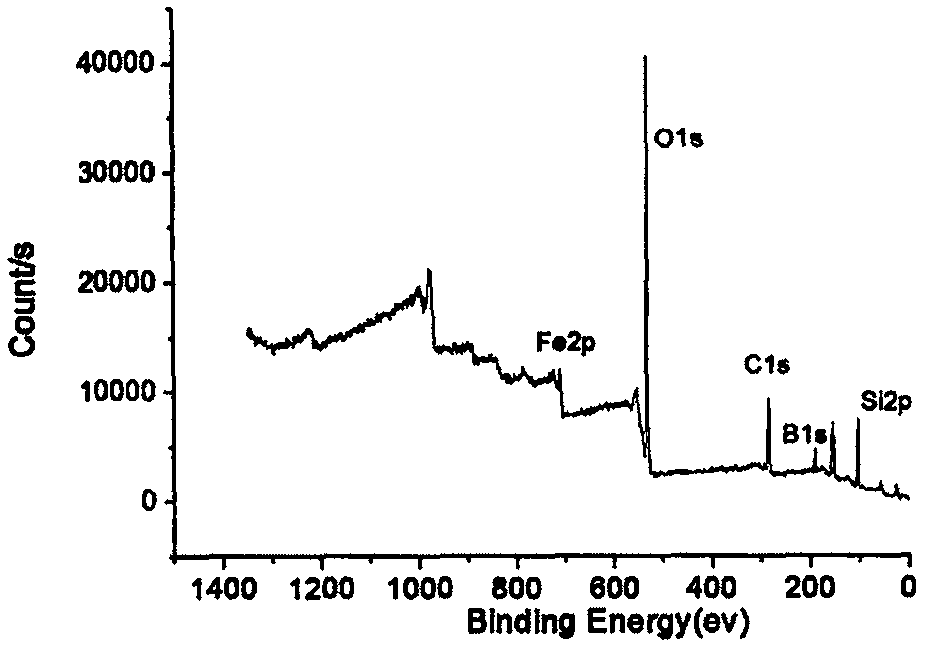

[0016] The present invention provides a technical solution: the present invention provides the following technical solution: a preparation method of a phenylboryl-modified covalent affinity magnetic solid-phase extraction agent, the inner core of which is ferric oxide, and the outer coating is triethoxy base silane, and modify the phenyl boron group on its surface, its synthesis steps and structure are as follows:

[0017]

[0018] Concrete steps of the present invention are:

[0019] A. With ferric oxide as the inner core, add triethoxysilane under acidic conditions, and carry out hydrolysis reaction at 70°C to coat the outer layer of ferric ferric oxide nanoparticles, magnetically separate and discard the reaction solution , to obtain ferric oxide particles coated with triethoxysilane;

[0020] B. Add the iron ferric oxide particles coated with triethoxysilane obtained in the above step A into DMF as the reaction solution, then add sodium carbonate to adjust the reaction...

Embodiment 1

[0023] The preparation of the covalent affinity type magnetic solid-phase extraction agent modified by phenylboryl group comprises the steps:

[0024] (a) Add 1.89g of anhydrous ferric chloride to a 100mL single-necked flask, add 70mL of ethylene glycol, stir for 30min to dissolve, add 4.8g of anhydrous sodium acetate, continue the reaction for 30min, and transfer to a polytetrafluoroethylene reactor After reacting at 200°C for 10h, take it out, cool to room temperature, wash with water and ethanol several times, and dry the ferric oxide spherical particles at 40°C for 24h in vacuum.

[0025] (b) Mix deionized water and ethanol according to the volume ratio of 1:8, adjust the pH to 4.0 with acetic acid, add triethoxysilane with the same volume as deionized dropwise under stirring, and stir at room temperature for 4 hours, make it fully hydrolyzed;

[0026] (c) In a 100ml three-necked flask equipped with a reflux condenser and a thermometer, add the hydrolyzate obtained in (b)...

Embodiment 2

[0032] The covalent affinity magnetic nanoparticles modified by the phenylboryl group of this example are used as a magnetic solid-phase extraction agent to selectively adsorb rare precious metal rubidium ions in aqueous solution. The steps are:

[0033](a) Preparation of stock solution: Accurately weigh 10 mg of rubidium chloride standard substance, dissolve in deionized water and make up to 10 mL.

[0034] (b) Prepare the solution to be tested: accurately pipette 100 μL of the stock solution prepared in step (a), and dilute to 10 mL with deionized water.

[0035] (c) SPE activation step: Accurately weigh 100mg of the prepared magnetic SPE, activate with 5ml of methanol and 3mL of 0.13% acetic acid solution (pH=3) successively, and separate the extraction agent and the solution with an external magnetic field each time , and the supernatant was discarded, and then washed several times with deionized water until the pH of the extractant was approximately neutral.

[0036] (e)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com