4.40V high-voltage lithium cobalt oxide material and production method thereof

A lithium cobalt oxide, high-voltage technology, applied in circuits, electrical components, battery electrodes, etc., to achieve the effect of improving morphology and ensuring cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

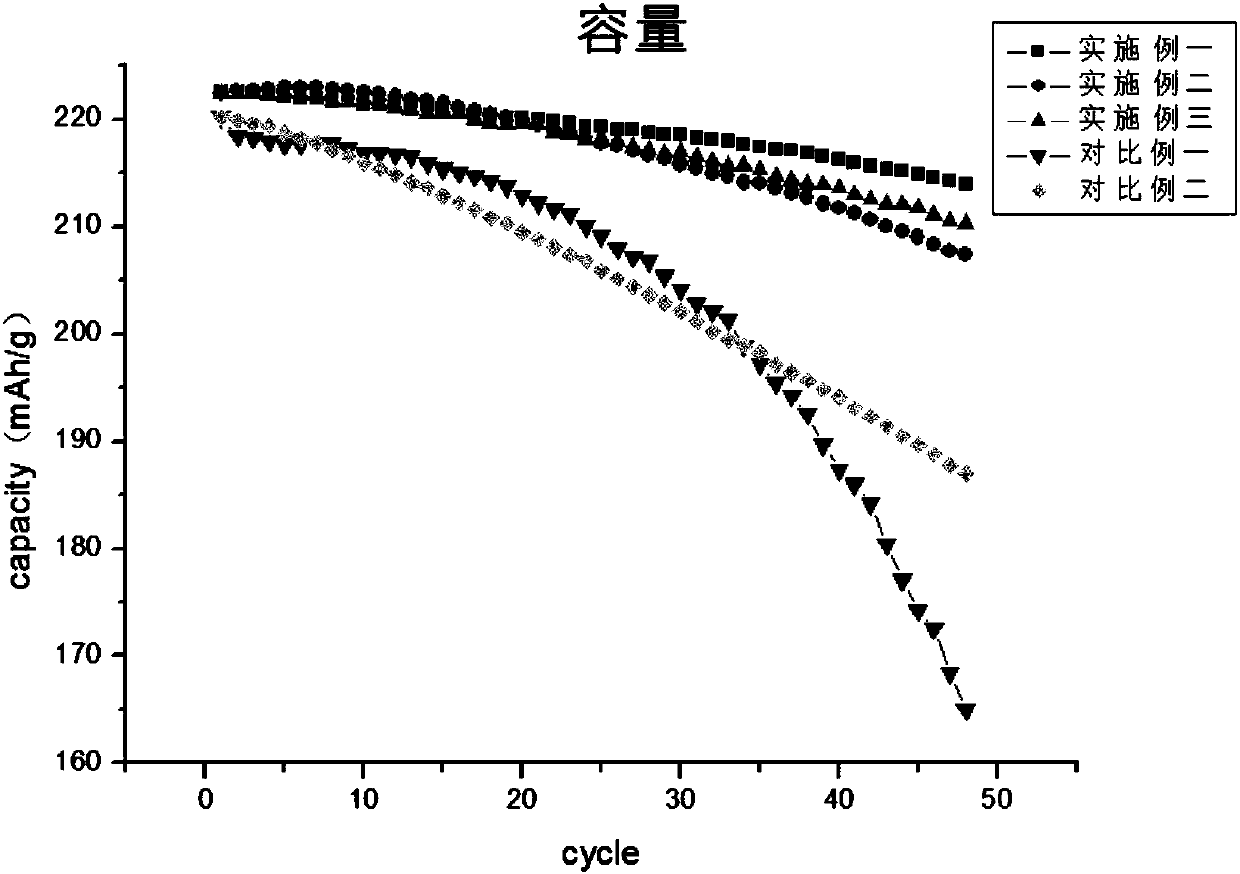

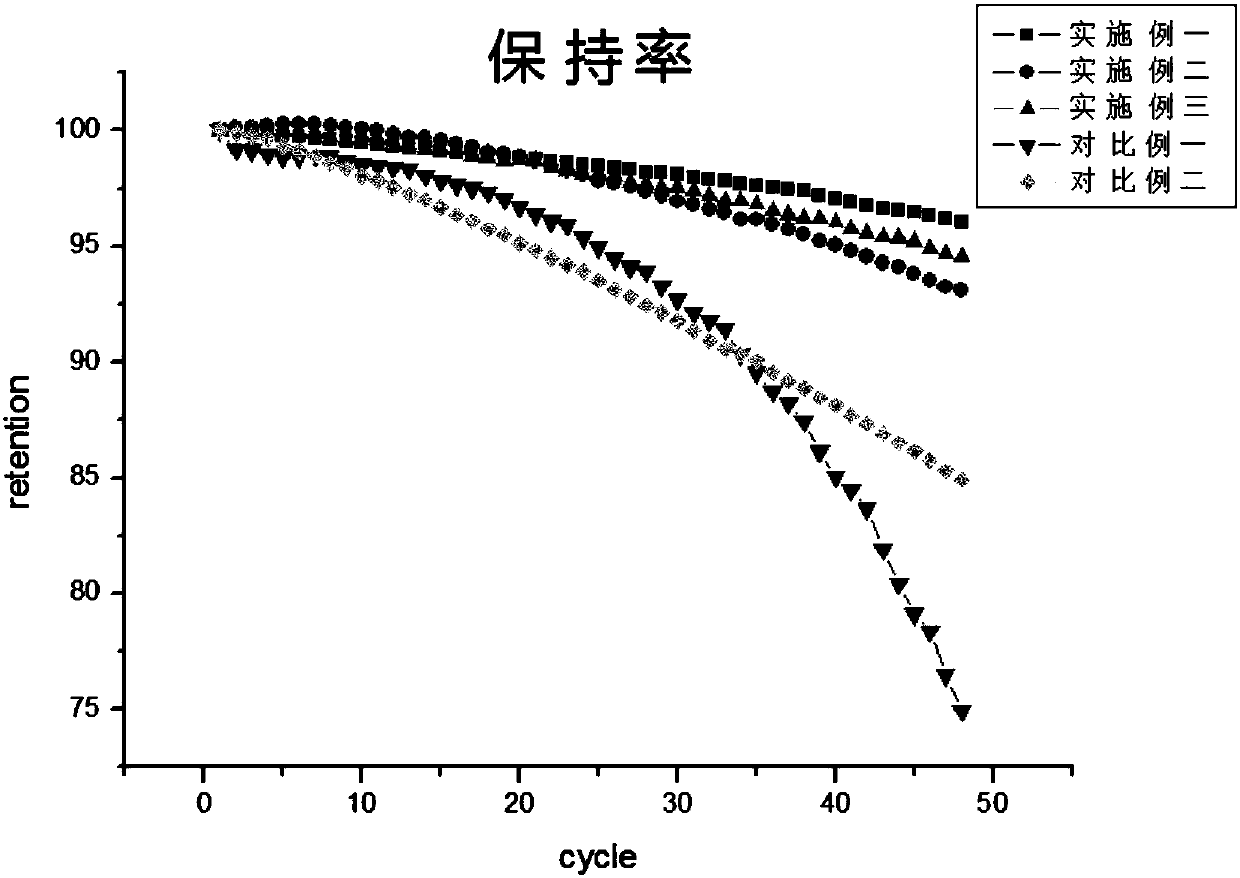

Examples

preparation example Construction

[0024] The preparation method of the 4.40V high-voltage lithium cobaltate material provided by the invention comprises the following steps:

[0025] S1. Select cobalt oxide A, mix with lithium source, compound containing doping elements Mg, Al, Ti, W, sinter, crush, sieve, and remove iron to obtain lithium cobalt oxide material C1.

[0026] The lithium source is a mixture of one or more of lithium carbonate, lithium hydroxide and lithium oxalate, the median particle size of cobalt oxide A is 11-20 μm, and the molar ratio of lithium-cobalt is (0.90-1.10):1 , the median particle size of the obtained lithium cobalt oxide material C1 is 13-22 μm. The compound containing doping elements Mg, Al, Ti and W is derived from one or two of oxides, hydroxides and fluorides of each element. In this step, the sintering temperature is 1000-1100° C., and the holding time is 3-12 hours.

[0027] S2. Select cobalt oxide B, mix with lithium source, compound containing doping elements Mg, Ni, Mn...

Embodiment 1

[0039] Cobalt oxide with a D50 of 15 μm is selected, and the sources of doping elements Mg, Al, Ti, and W are magnesium hydroxide, aluminum oxide, titanium oxide, and tungsten oxide, respectively. The molar ratio of lithium to cobalt is 1.025, and the amount of doping elements Mg-1000ppm, Al-550ppm, Ti-500ppm, W-500ppm takes cobalt oxide, lithium carbonate, magnesium hydroxide, aluminum oxide, titanium oxide, and tungsten oxide. After they are mixed, they are sintered in a box furnace at 1100°C for 9 hours in an air atmosphere; after the sintering is completed, the primary sintered product is crushed, iron-removed, and sieved to obtain a lithium cobalt oxide material C1 with a D50 of 20.2 μm.

[0040] Cobalt oxide with a D50 of 3 μm is selected, and the sources of doping elements Mg, Ni, and Mn are magnesium hydroxide, nickel oxide, and manganese dioxide, respectively. According to the molar ratio of lithium-cobalt being 1.0, the amount of doping elements Mg-1200ppm, Ni-700ppm...

Embodiment 2

[0045] Cobalt oxide with a D50 of 15 μm is selected, and the sources of doping elements Mg, Al, Ti, and W are magnesium hydroxide, aluminum oxide, titanium oxide, and tungsten oxide, respectively. The molar ratio of lithium to cobalt is 1.025, and the amount of doping elements Mg-1000ppm, Al-550ppm, Ti-500ppm, W-500ppm takes cobalt oxide, lithium carbonate, magnesium hydroxide, aluminum oxide, titanium oxide, and tungsten oxide. After they are mixed, they are sintered in a box furnace at 1100°C for 9 hours in an air atmosphere; after the sintering is completed, the primary sintered product is crushed, iron-removed, and sieved to obtain a lithium cobalt oxide material C1 with a D50 of 20.2 μm.

[0046] Cobalt oxide with a D50 of 3 μm is selected, and the sources of doping elements Mg, Ni, and Mn are magnesium hydroxide, nickel oxide, and manganese dioxide, respectively. According to the molar ratio of lithium-cobalt being 1.0, the amount of doping elements Mg-1200ppm, Ni-700ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com