Method of degrading aflatoxin in peanut meal and synchronously preparing peanut protein peptide

A technology of aflatoxin and peanut protein, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of unreported multi-bacteria combined on aflatoxin degradation, strains are not easy to grow and reproduce, and affect consumers. Health and other issues, to achieve the effect of shortening fermentation time, easy industrial production, and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

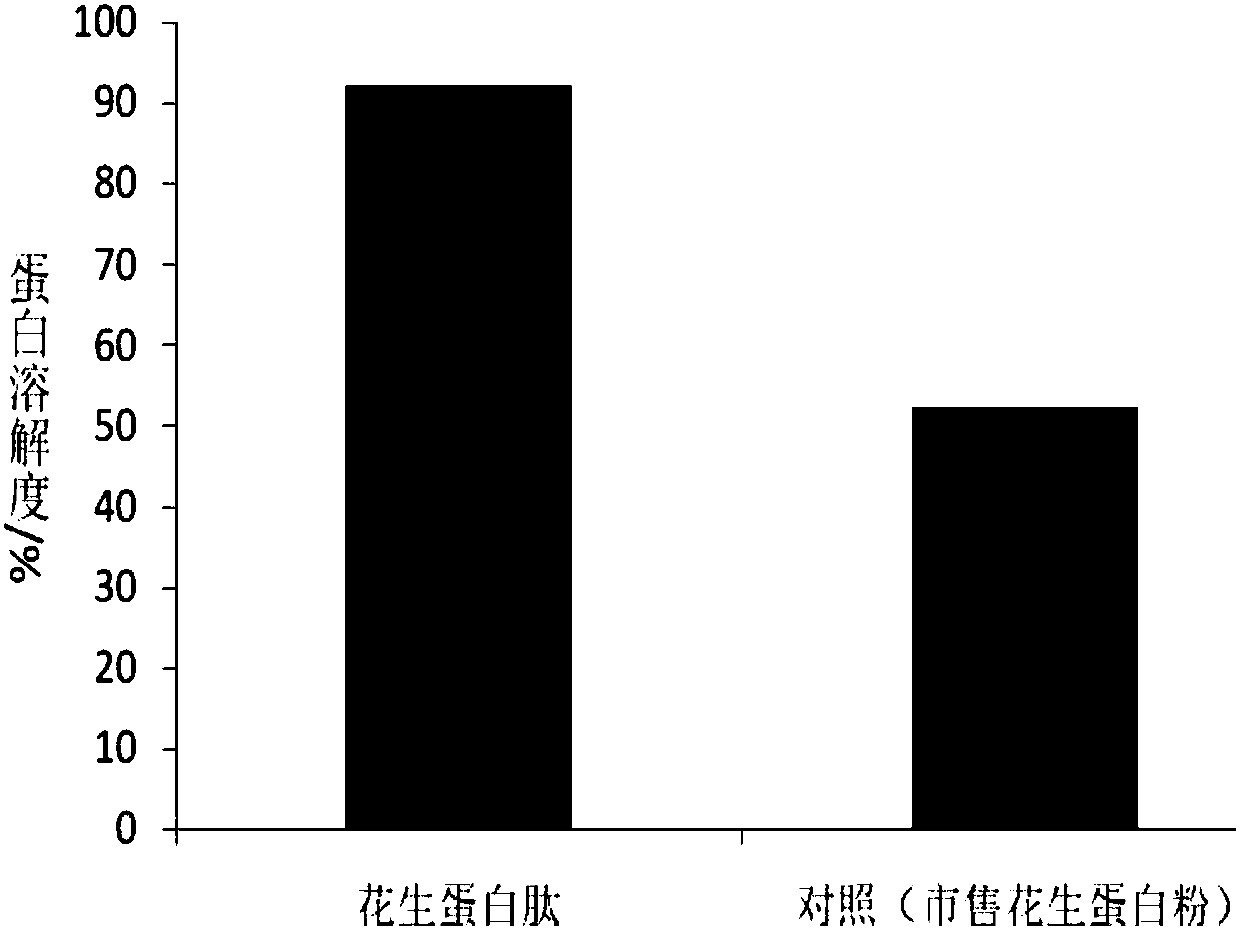

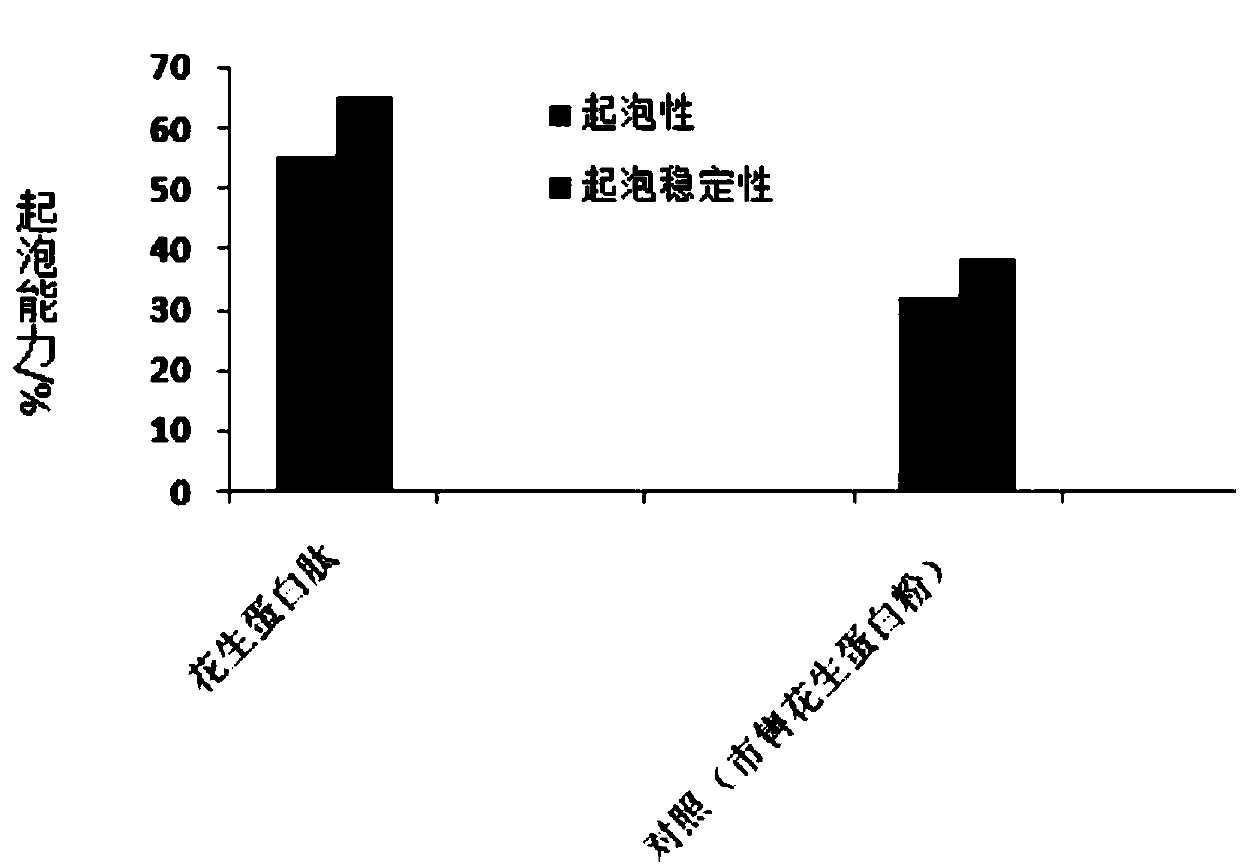

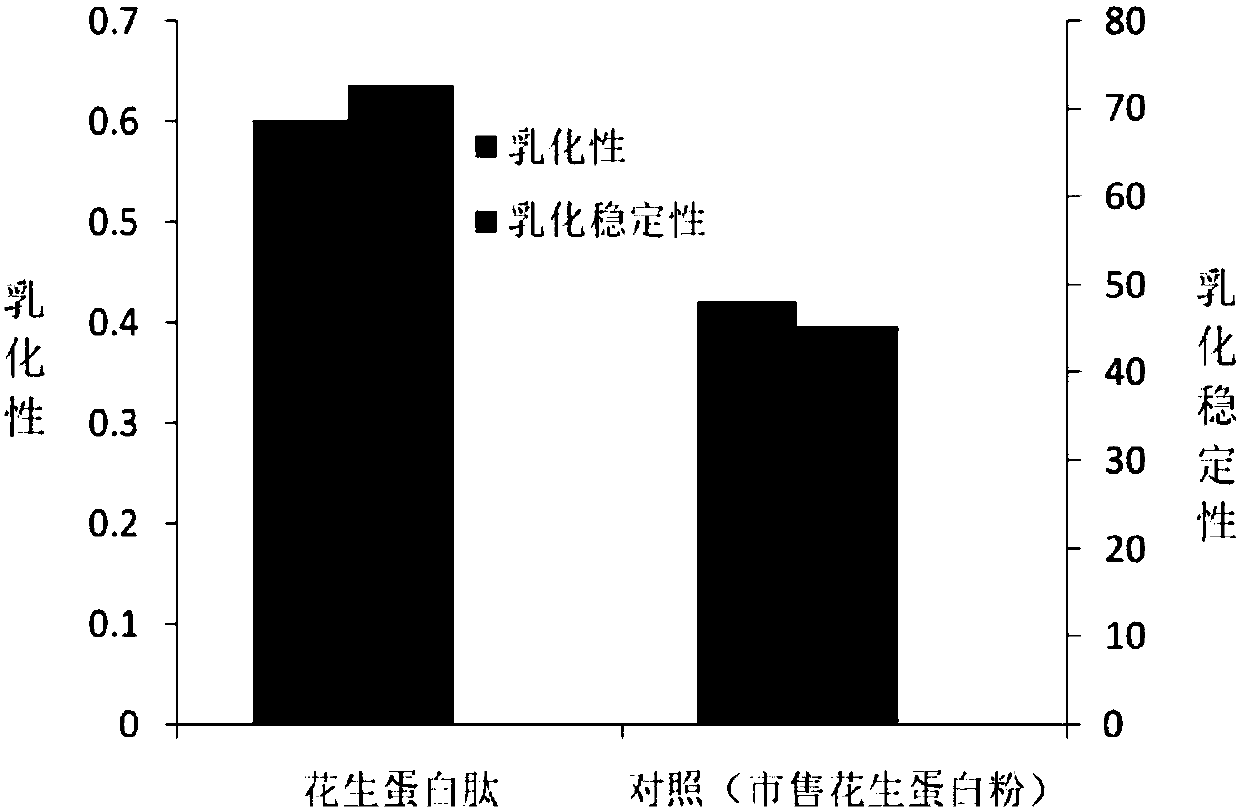

Embodiment 1

[0052] The total amount of aflatoxins in peanut meal raw materials is 92 μg / kg (wherein B 1 is 55 μg / kg, B 2 is 16 μg / kg, G 1 is 19 μg / kg, G 2 is 2 μg / kg), and the cyclopiazonic acid content is 52 μg / kg. Add 10g of peanut meal to 20mL of water, sterilize, inoculate 1g of Versicolor versicolor strain activated by peanut root fermentation, solid fermentation at 25°C for 8 days, then inoculate 1mL of Bacillus subtilis strain activated by peanut meal aqueous solution into the fermented peanut meal, Solid fermentation at 30°C for 3 days, then inoculate peanut meal with 1g of Aspergillus niger activated from peanut roots, solid fermentation at 35°C for 3 days; add 30mL of distilled water to the fermented medium, shake at 33°C for 2 hours, then shake at 25°C for enzymolysis 8h; the enzymolysis solution was treated at 100°C for 15 minutes, cooled to room temperature and centrifuged at 10,000rpm for 10 minutes; Air volume is 22m 3 / h, after the drying is completed, the peanut prot...

Embodiment 2

[0057] The total amount of aflatoxins in peanut meal raw materials is 92 μg / kg (wherein B 1 is 55 μg / kg, B 2 is 16 μg / kg, G 1 is 19 μg / kg, G 2 is 2 μg / kg), and the cyclopiazonic acid content is 52 μg / kg. Add 10g of peanut meal to 20mL of water, sterilize, inoculate 0.7g of Versicolor versicolor strain activated by peanut root fermentation, solid fermentation at 28°C for 6 days, and inoculate 0.7 Bacillus subtilis strain activated by peanut meal aqueous solution into the fermented peanut meal mL, solid fermentation at 32°C for 4 days, then inoculate peanut meal with 0.7 g of Aspergillus niger activated from peanut roots, and solid fermentation at 32°C for 4 days; add 40 mL of distilled water to the fermented medium, shake and enzymolyze at 34°C for 1.5 hours, 23 ℃ shaking enzymolysis for 10 hours; enzymatic hydrolysis solution at 100 ℃ for 15 minutes, cooling to room temperature and centrifuging at 10,000 rpm for 10 minutes in a high-speed centrifuge; spray drying the supern...

Embodiment 3

[0062] The total amount of aflatoxins in peanut meal raw materials is 92 μg / kg (wherein B 1 is 55 μg / kg, B 2 is 16 μg / kg, G 1 is 19 μg / kg, G 2 is 2 μg / kg), and the cyclopiazonic acid content is 52 μg / kg. Add 10g of peanut meal to 25mL of water, sterilize, inoculate 0.7g of Versicolor versicolor strain activated by peanut root fermentation, solid fermentation at 28°C for 6 days, and then inoculate 0.7 Bacillus subtilis strain activated by peanut meal aqueous solution into the fermented peanut meal mL, solid fermentation at 32°C for 4 days, then inoculate peanut meal with 0.7 g of Aspergillus niger activated from peanut roots, and solid fermentation at 32°C for 4 days; add 40 mL of distilled water to the fermented medium, shake at 35°C for 1 hour, then inoculate at 22°C Shake enzymatic hydrolysis for 12 hours; enzymatic hydrolysis solution was deactivated at 100°C for 15 minutes, cooled to room temperature, and centrifuged at 10,000 rpm for 10 minutes in a high-speed centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com