Magnetic core-shell type porous Calcium silicate material and preparation method thereof

A porous calcium silicate, core-shell technology, applied in chemical instruments and methods, silicon compounds, other chemical processes, etc., can solve the problems of discontinuous process, cumbersome operation process, low efficiency, etc., to reduce agglomeration and simplify separation. The effect of manipulating and reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

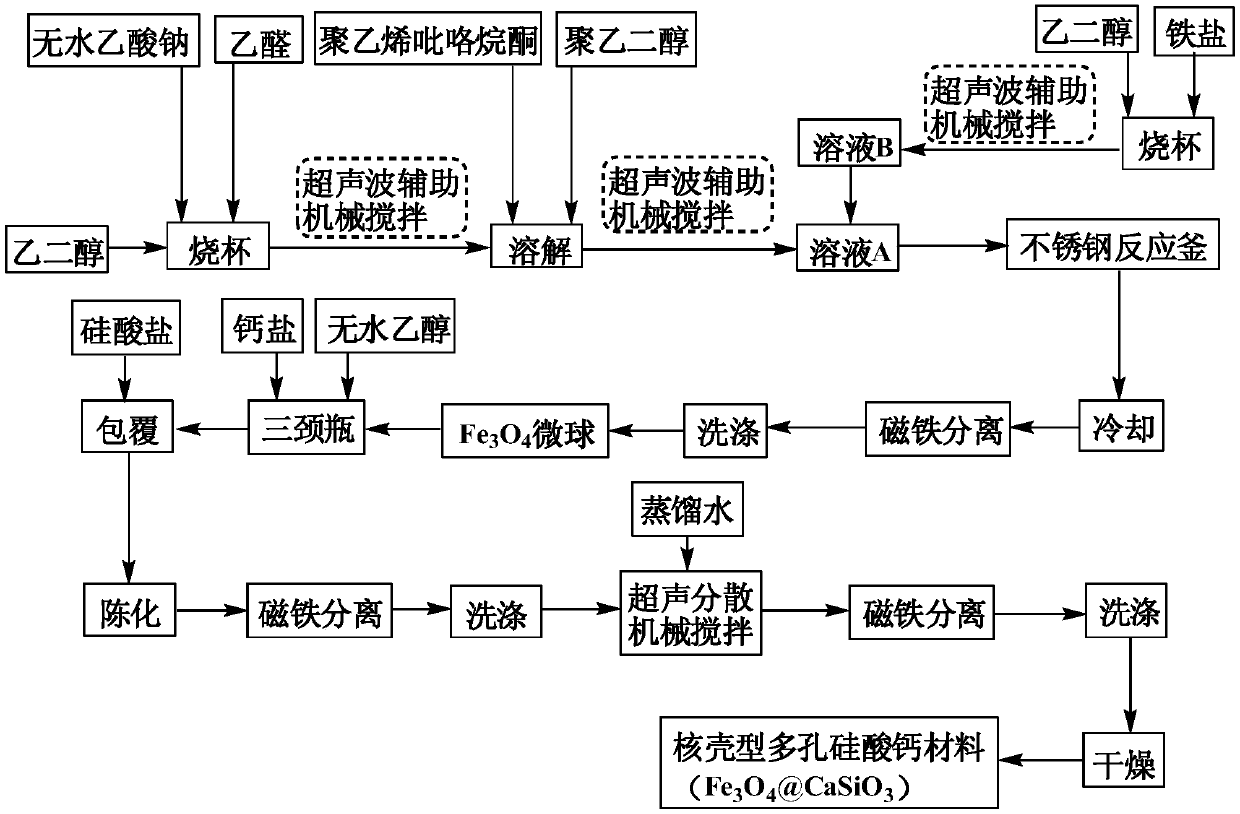

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix 22.89g of anhydrous sodium acetate with 137mL of ethylene glycol, add 5.3mL of acetaldehyde, and dissolve with ultrasonic-assisted mechanical stirring, then add 7.63g of polyethylene glycol 4000 and 6.54g of polyvinylpyrrolidone PVP K17, After dissolving with ultrasonic-assisted mechanical stirring, place it in constant temperature water at 45°C for later use to obtain solution A; weigh 25.14g of ferric chloride hexahydrate and add it to 151mL of ethylene glycol, and dissolve with ultrasonic-assisted mechanical stirring to obtain solution B; B was slowly added dropwise to solution A under vigorous stirring, continued to stir for 30 min after the addition, and then transferred to a 500 mL stainless steel reactor with a polytetrafluoroethylene liner, and reacted at 150 ° C for 5 h. After cooling to room temperature, use magnet adsorption to separate from the reaction solution, and then wash 5 times with deionized water and 3 times with absolute ethanol to obtain ma...

Embodiment 2

[0032] (1) Mix 22.89g of anhydrous sodium acetate with 172mL of ethylene glycol, add 5.0mL of acetaldehyde, and dissolve with ultrasonic-assisted mechanical stirring, then add 5.72g of polyethylene glycol 4000 and 5.09g of polyvinylpyrrolidone PVP K17, After dissolving with ultrasonic-assisted mechanical stirring, place it in constant temperature water at 50°C for later use to obtain solution A; weigh 21.55g of ferric chloride hexahydrate and add it to 120mL of ethylene glycol, and dissolve with ultrasonic-assisted mechanical stirring to obtain solution B; B was slowly added dropwise to solution A under vigorous stirring, continued to stir for 40 min after the addition, and then transferred to a 500 mL stainless steel reactor with a polytetrafluoroethylene liner, and reacted at 140 ° C for 8 h. After cooling to room temperature, use magnet adsorption to separate from the reaction solution, then wash with deionized water for 4 times and absolute ethanol for 2 times to obtain mag...

Embodiment 3

[0035] (1) Mix 22.89g of anhydrous sodium acetate with 114.5mL of ethylene glycol, add 5.1mL of acetaldehyde, and dissolve with ultrasonic-assisted mechanical stirring, then add 6.54g of polyethylene glycol 4000 and 4.58g of polyvinylpyrrolidone PVP K17 , ultrasonically assisted mechanical stirring and dissolving, and placed in constant temperature water at 40°C for later use to obtain solution A; weigh 30.16g of ferric chloride hexahydrate and add it to 151mL of ethylene glycol, and ultrasonically assisted mechanical stirring to dissolve to obtain solution B; then Solution B was slowly added dropwise to solution A under vigorous stirring, and continued to stir for 35 minutes after the addition, and then transferred to a 500 mL stainless steel reactor with a polytetrafluoroethylene liner, and reacted at 160 ° C for 4 hours. After cooling to room temperature, use magnet adsorption to separate from the reaction solution, and then wash 5 times with deionized water and 3 times with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com