Molybdenum sulfide-ferrite nano-enzyme as well as preparation and application

A technology of ferrite and molybdenum sulfide, applied in the direction of molybdenum sulfide, inorganic chemistry, iron compounds, etc., can solve the problems of complex operation and high cost, and achieve the effects of high catalytic activity, high specific surface area and strong catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042](1) Weigh 5.8 mmoles of ferric chloride hydrate, 2.9 mmoles of magnesium chloride hydrate and 8.0 mmoles of dodecylamine, dissolve them in 75 ml of ethylene glycol, and stir well at room temperature;

[0043] (2) Transfer the mixed solution of step (1) into a 100ml autoclave, and react at 220°C for 20 hours;

[0044] (3) After the reaction product in step (2) is centrifuged to remove water (rotation speed: 4500 rpm), it is washed with deionized water repeatedly for 3 to 5 times until the pH value of the solution is close to 7.0, and the washed reaction product is placed at 55°C Under drying for 10 hours to obtain ferrite magnesium;

[0045] (4) Weigh 0.54 mmol of ammonium tetrathiomolybdate and dissolve it in 65 ml of dimethylformamide;

[0046] (5) Slowly add 1.0 ml of hydrazine hydrate to the mixture obtained in step (4), and stir for 0.5 hours to ensure that it is evenly mixed;

[0047] (6) Weighing 0.3 mmol of ferrite magnesium obtained in step (3), and dispersing ...

Embodiment 2

[0053] a) Disperse 1 mg of molybdenum sulfide-magnesium ferrite nanozyme in Example 1 in 1 milliliter of deionized water to obtain a 1 mg / ml molybdenum sulfide-magnesium ferrite dispersion;

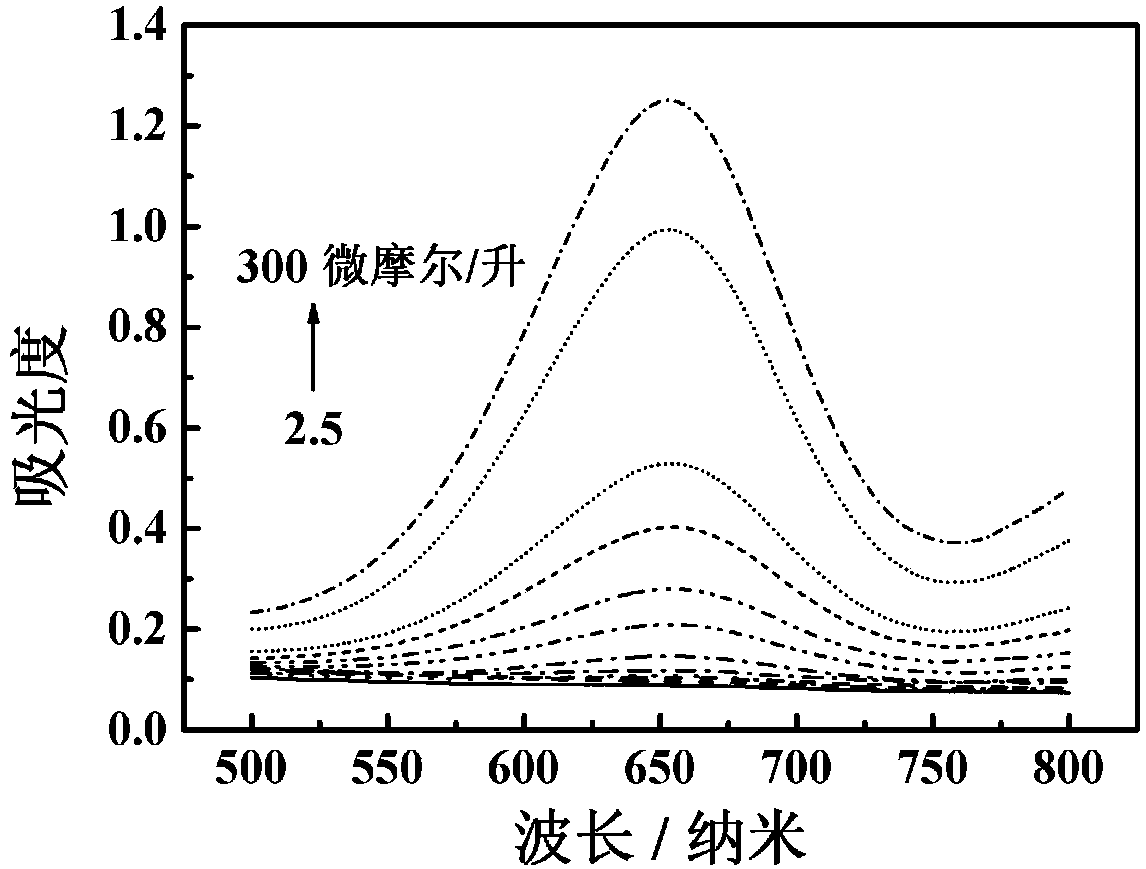

[0054] b) Measure 10 microliters of the mixture in step a), 250 microliters, 2 mmol / L TMB and 100 microliters of 2.5~300 micromol / L hydrogen peroxide in 0.1 mol / L, pH 4.0 acetic acid-sodium acetate buffer;

[0055] c) incubating the mixture obtained in step b) at 45° C. for 15 minutes;

[0056] d) Utilize a spectrophotometer to measure the concentration of hydrogen peroxide in the mixed solution obtained in step c).

[0057] figure 2 It is the ultraviolet absorption spectrogram of the molybdenum sulfide-ferrite magnesium nanozyme of the present invention detecting hydrogen peroxide at different concentrations.

[0058] The method for detecting hydrogen peroxide by molybdenum sulfide-ferrite magnesium nanozyme in the present invention is further described in conjunction with specific e...

Embodiment 3

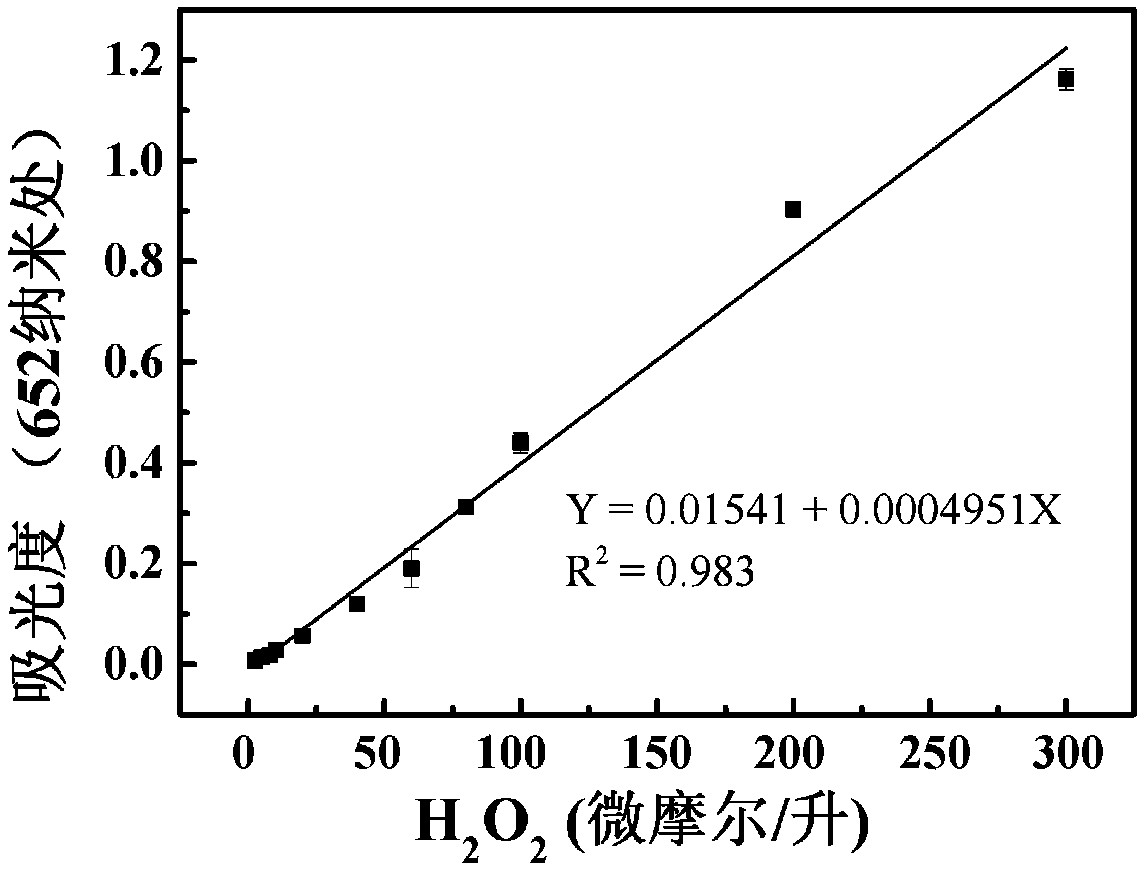

[0060] The absorbance at 652 nanometers in Example 2 is plotted with the concentration of hydrogen peroxide ( image 3 ), a linear relationship diagram can be obtained.

[0061] From image 3 It can be seen that the molybdenum sulfide-magnesium ferrite nanozyme maintains a good linear relationship to hydrogen peroxide in the range of 2.5 to 300 micromol / liter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com