An ag nanowire/cu 2 o Core-shell structure and its preparation method

A core-shell structure and nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as slow response and complicated operation, and achieve fast response, simple operation, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, Ag nanowire / Cu 2 Photochemical preparation of O core-shell structure

[0043] Preparation of Ag Nanowires / Cu by Photochemical Method 2 O core-shell structure, specifically comprises the following steps:

[0044] (1) First, take 0.3g of copper acetate monohydrate, 0.1g of polyvinylpyrrolidone (PVP) and 3mL of ethylene glycol and dissolve them in 6mL of ultrapure water, and use a magnetic stirrer to stir continuously at a speed of 400rpm until completely dissolved. Obtain the precursor solution.

[0045] (2) Use a pipette gun to extract 2 mL of the solution from the precursor solution in step (1) and inject it into a beaker with a capacity of 25 mL, then add 500 μL of silver nanowire ethanol solution (concentration is 0.5 mg / ml) to obtain a mixed solution, Then it was placed on a stirring table and stirred at a rotation speed of 400 rpm.

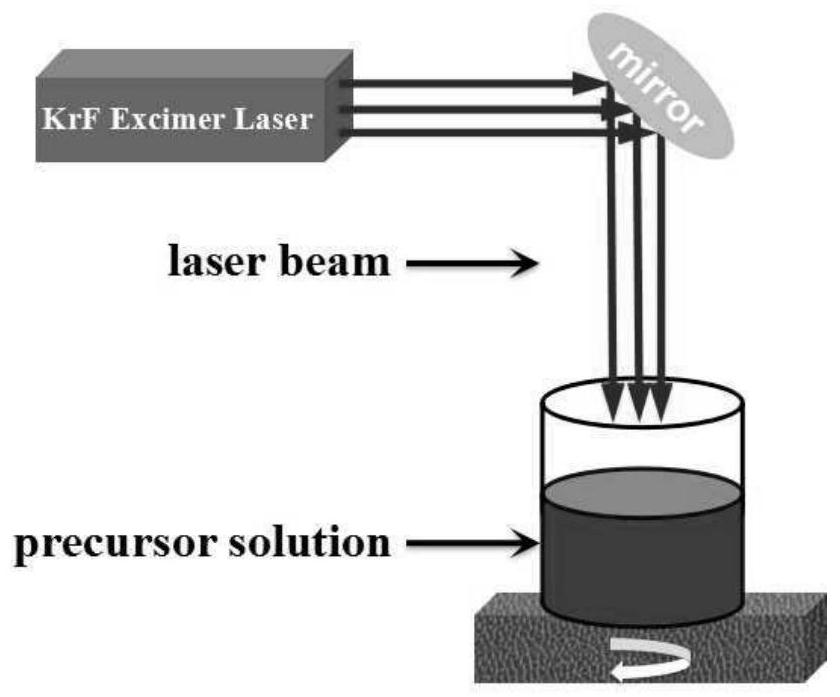

[0046] (3) Utilize KrF excimer laser (output wavelength is 248nm) to irradiate in the precursor solution in the beak...

Embodiment 2

[0048] Embodiment 2, Ag nanowire / Cu 2 Photochemical preparation of O core-shell structure

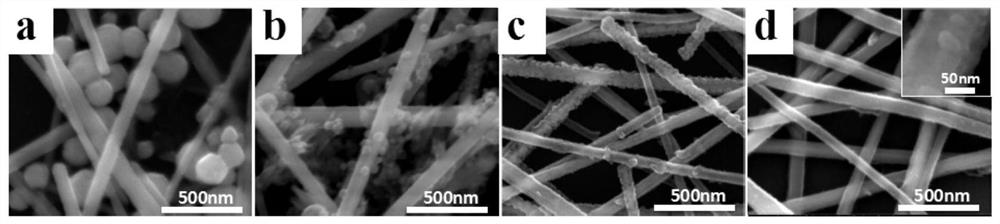

[0049] The same as the preparation method in Example 1 of the present invention, the difference is that in step (1) of Example 1 of the present invention, the intake of polyvinylpyrrolidone (PVP) is changed to 0g, 0.01g, 0.05g, 0.1g, Cu coated on Ag nanowires 2 The particle size of O nanocrystals becomes smaller gradually, and the coating is denser, the results are as follows image 3 a—shown in Figure 3d.

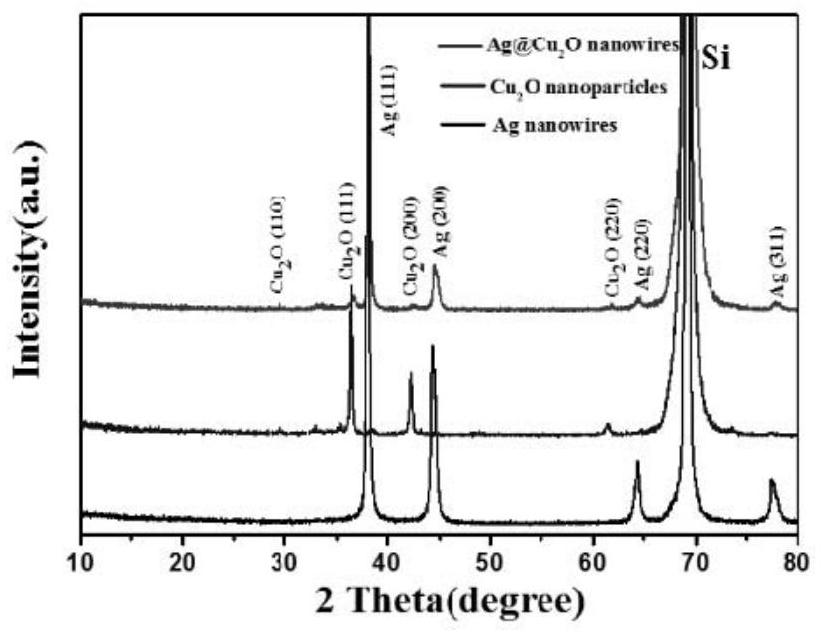

[0050] The Ag nanowire / Cu that present embodiment prepares 2 O core-shell structure, by SEM ( image 3 , 4 ) image shows that Ag nanowires / Cu 2 The core diameter of the Ag nanowires in the O core-shell structure is 70-90nm, the length is 10-15um, the Cu 2 The particle size of O nano crystal shell is 20-500nm. Depend on image 3 The analysis shows that when changing the intake of polyvinylpyrrolidone (PVP) to 0g, Cu 2 O particle size is 130-350nm, and agglomerated on the su...

Embodiment 3

[0051] Embodiment 3, Ag nanowire / Cu 2 Photochemical preparation of O core-shell structure

[0052] Identical to the preparation method in the embodiment of the present invention 1, the difference is that the KrF excimer laser measurement condition in the step (3) of the embodiment of the present invention 1 is changed, and the measured results are as follows: Figure 4 A- Figure 4 D shows. Depend on Figure 4 A- Figure 4 D shows that when the single pulse energy of the laser is changed to 20mJ, Cu 2 Many Cu appear in the O nanoshell 2 O petal-like structure, the length of the two tips of the petals is 150-200nm, with the extension of laser irradiation time 1min, 3min, 6min, 9min, the Cu on the surface of the Ag nanowire 2 The petal-like structure of O increased slightly, and the thickness of the shell increased slightly, from 20nm to 35nm; Figure 4 E- Figure 4 As shown in H, when the laser single pulse energy is increased to 80mJ, Cu 2 O petal-like structure disap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com