Method for preparing sugar alcohol and coproducing white carbon black

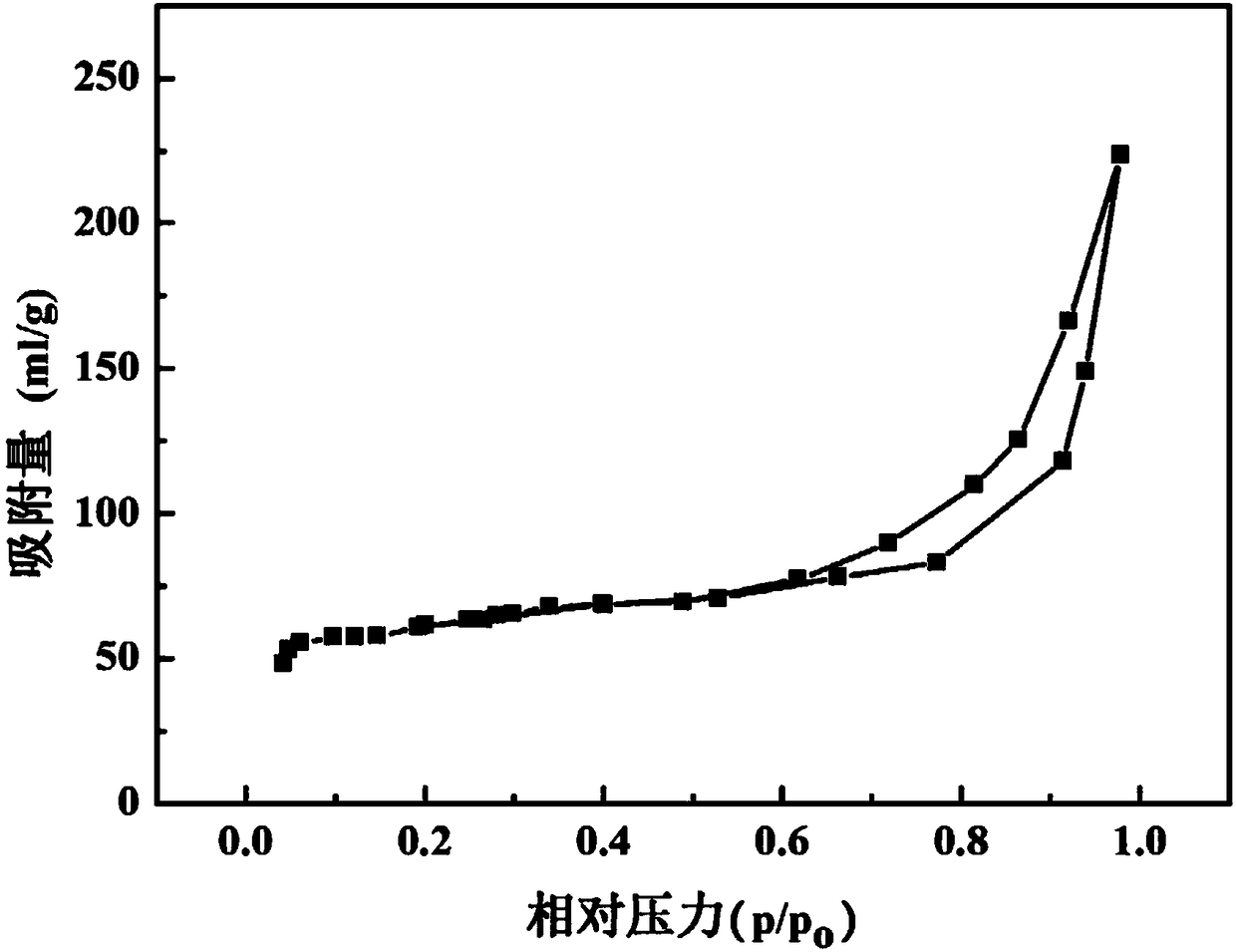

A technology of white carbon black and sugar alcohol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem that sugar alcohol products cannot be directly obtained, the purity of xylose cannot be guaranteed, and the specific surface area has not been found and other issues, to achieve huge economic and environmental benefits, novel preparation methods, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing sugar alcohol co-production white carbon black, the steps are as follows:

[0055] (1) Add 400Kg potassium hydroxide and 1000Kg water into the reactor, stir at room temperature until there are no solid particles, and obtain solution A;

[0056] (2) Add 800Kg of glucose to the solution A prepared in step (1), and stir at room temperature until there are no solid particles to obtain solution B;

[0057] (3) 100Kg of silicon is added to the solution B prepared in step (2), then 8Kg of Raney nickel is added, then the reaction kettle is sealed, and nitrogen replacement is performed 3 times;

[0058] (4) Heat the reactor to 130°C, stir for 5 hours, cool down to room temperature, and then filter through a filter to obtain filtrate C and filter residue D, which is returned to the reactor in step (3) for recycling, and the filtrate C is Sugar Alcohol Silicon Solution.

[0059] (5) Add hydrochloric acid to the filtrate C, adjust the pH to 6-7, heat up to ...

Embodiment 2

[0063] A method for preparing sugar alcohol co-production white carbon black, the steps are as follows:

[0064] (1) Add 200Kg potassium hydroxide and 1000Kg water into the reactor, stir at room temperature until there are no solid particles, and obtain solution A;

[0065] (2) Add 300Kg of xylose to the solution A prepared in step (1), stir at room temperature until there are no solid particles, and obtain solution B;

[0066] (3) 50Kg of silicon is added in the solution B prepared in step (2), then 5Kg of palladium carbon is added, then the reaction kettle is sealed, and the nitrogen is replaced 4 times;

[0067] (4) Heat the reactor to 170°C, stir for 3 hours, cool down to room temperature, then filter through a filter to obtain filtrate C and filter residue D, and return the filter residue D to the reactor in step (3) for recycling, and the filtrate C is Sugar Alcohol Silicon Solution.

[0068] (5) Add hydrochloric acid to filtrate C, adjust the pH to 6-7, heat up to 70°...

Embodiment 3

[0072] A method for preparing sugar alcohol co-production white carbon black, the steps are as follows:

[0073] (1) Add 500Kg sodium hydroxide and 1000Kg water into the reaction kettle, stir at room temperature until there are no solid particles, and obtain solution A;

[0074] (2) Add 1000Kg glucose to the solution A prepared in step (1), stir at room temperature until there are no solid particles, and obtain solution B;

[0075] (3) 125Kg of silicon is added in the solution B prepared in step (2), then 5Kg of palladium carbon is added, then the reaction kettle is sealed, and nitrogen replacement is performed 3 times;

[0076] (4) Heat the reactor to 120°C, stir for 15 hours, cool down to room temperature, and then filter through a filter to obtain filtrate C and filter residue D, and return the filter residue D to the reactor in step (3) for recycling, and the filtrate C is Sugar Alcohol Silicon Solution.

[0077] (5) Add sulfuric acid to filtrate C, adjust the pH to 6-7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com