Novel heavy metal ion adsorbent and preparation method and use thereof

A technology of heavy metal ions and adsorbents, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem that the adsorption effect of heavy metal ions is easily affected by water quality and the mechanical strength of chitosan is not high. , application limitations of chitosan, etc., to achieve the effect of good adsorption effect, fast adsorption rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

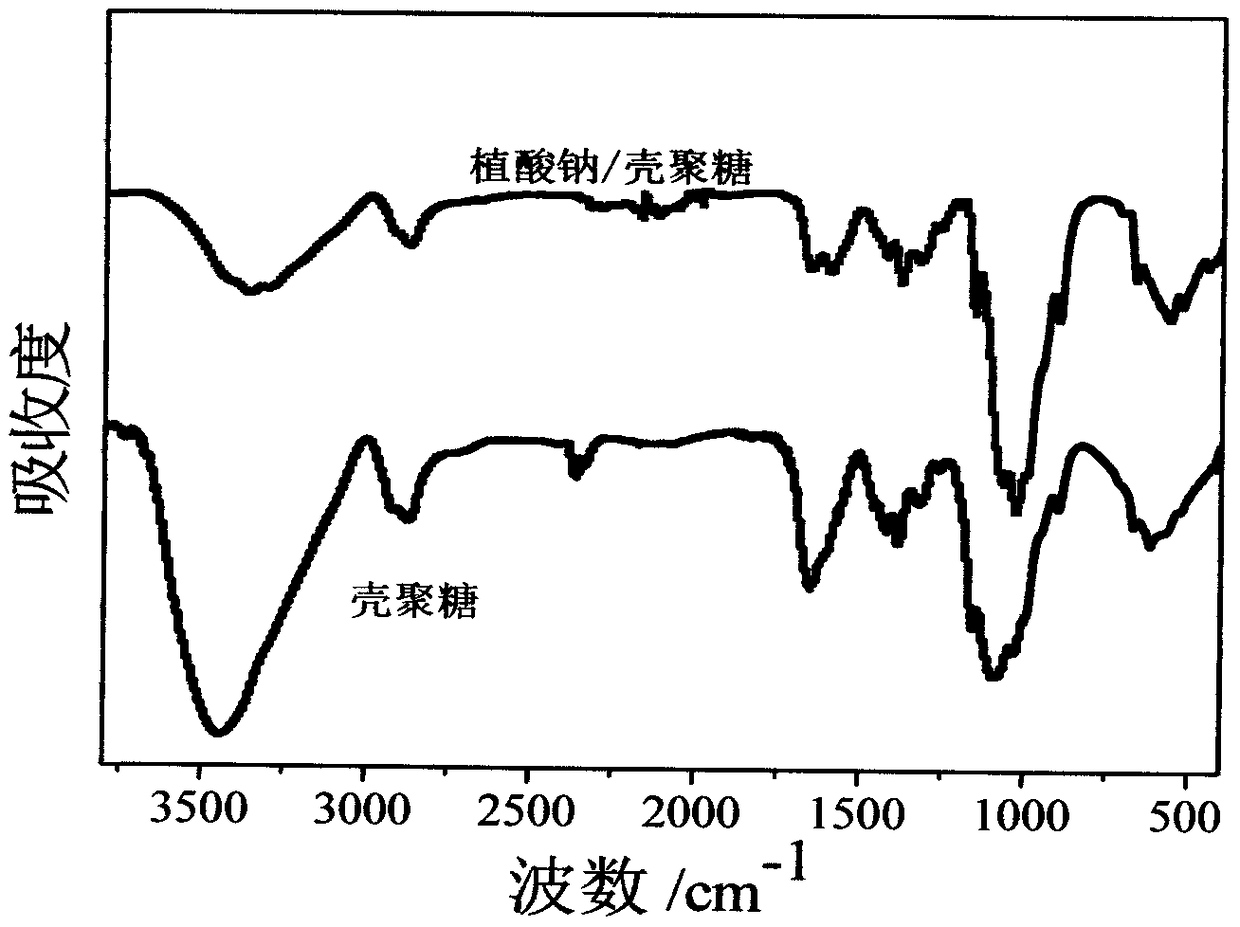

[0028] Example 1: Preparation of Chitosan Composite Resin

[0029] Weigh 2g with a molecular weight of 4×10 4 1. Chitosan powder with a degree of deacetylation of 95% is added with 98 g of acetic acid solution with a concentration of 1% by weight to fully dissolve it to form a light yellow transparent liquid. The above-mentioned 2% by weight chitosan solution was defoamed overnight and allowed to stand for 0.5 h for subsequent use.

[0030] Weigh 5 g of phytic acid and add 95 g of deionized water, and magnetically stir at room temperature until completely dissolved to obtain a 5% by weight phytic acid homogeneous solution. The pH of the solution was adjusted to 5 by sodium hydroxide and hydrochloric acid. Wherein, the deionized water contains glutaraldehyde cross-linking agent, and the weight concentration of glutaraldehyde is 1 gram / 100 gram of chitosan used.

[0031] Extract a certain amount of 2% by weight of chitosan solution with a syringe and inject it into 5% by weig...

Embodiment 1

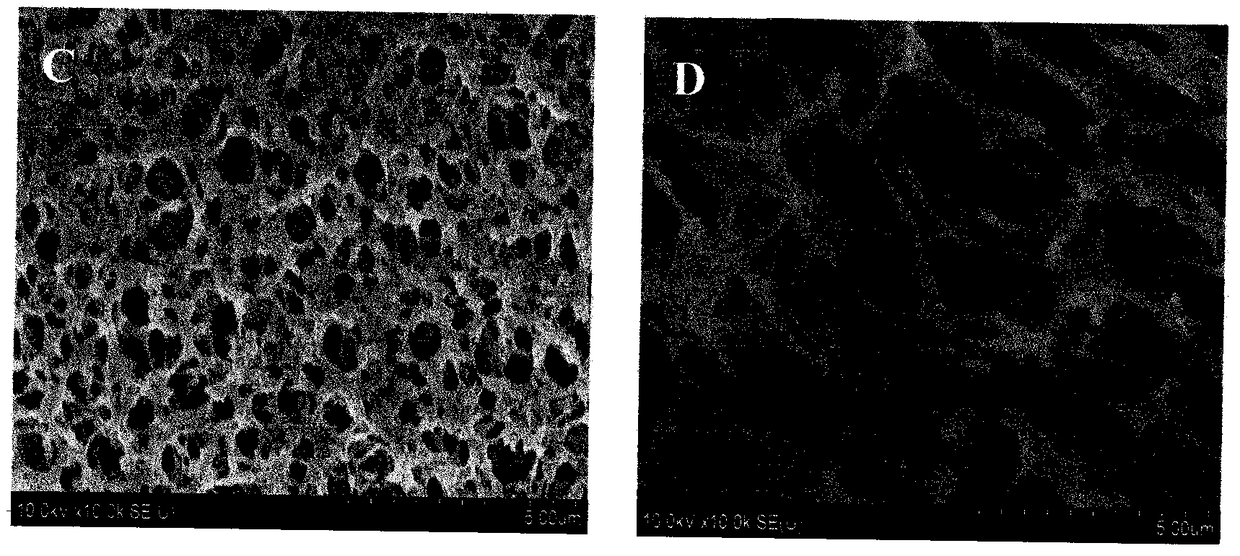

[0032] The surface of the resin obtained in Example 1 is transparent, the color is light yellow, and the hardness is relatively high.

example 2

[0033] Example 2: Preparation of sodium phytate / chitosan resin

[0034] Weigh 5g with a molecular weight of 1×10 5 1. The chitosan powder with a degree of deacetylation of 85% is added with 95 g of acetic acid solution with a concentration of 5% by weight to fully dissolve it to form a light yellow transparent liquid. The above-mentioned 5% chitosan solution was defoamed overnight and allowed to stand for 0.5 h for later use.

[0035] Weigh 9g of sodium phytate powder and add 91g of deionized water, and stir at room temperature until completely dissolved to obtain a 9% by weight sodium phytate homogeneous solution. The pH of the solution was adjusted to 9 by sodium hydroxide and hydrochloric acid. Wherein, the deionized water contains epichlorohydrin, and the weight concentration of epichlorohydrin is 5 grams per 100 grams of chitosan used.

[0036] Extract a certain amount of 5% by weight of chitosan solution with a syringe, drop it into 9% by weight of sodium phytate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com