Preparation method of modified konjac glucomannan loaded copper sustained-release agent and its application in water bloom control

A technology of konjac glucomannan and sustained-release agent, which is applied in the preparation of modified konjac glucomannan-loaded copper sustained-release agent and in the application field of water bloom control, which can solve the secondary pollution of water body and the concentration of copper sulfate High, harmful to aquatic organisms and other issues, to achieve the effect of avoiding slow-release ability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

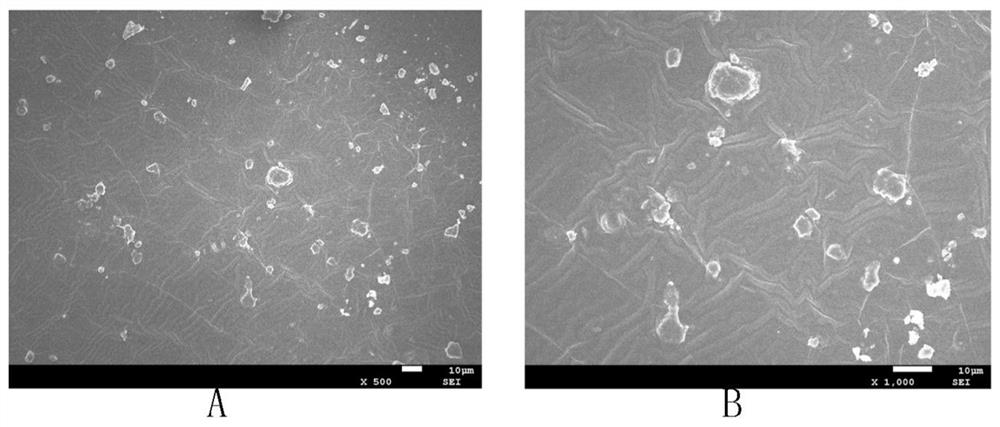

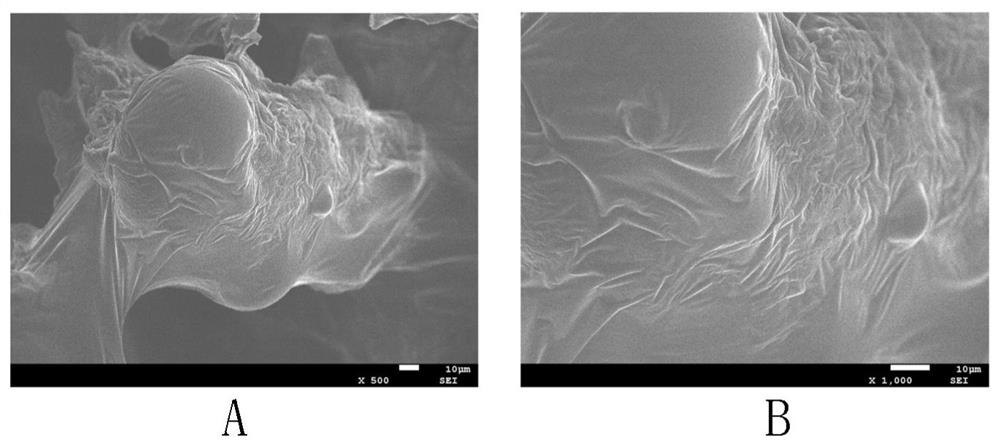

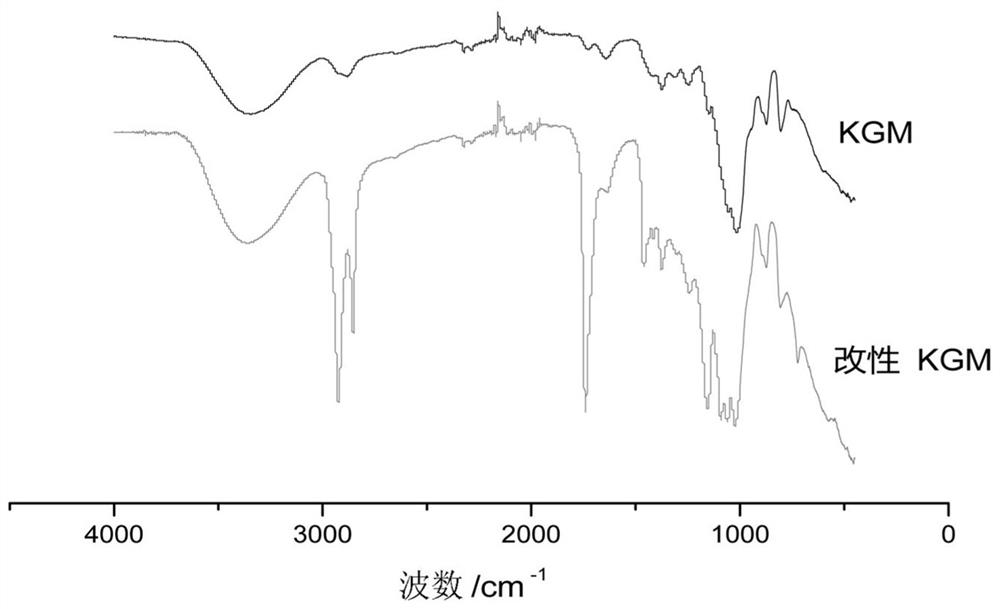

Embodiment 1

[0025] Fresh konjac was dried and crushed, sieved, purified by ethanol and then dried; weighed 1.0 g of purified konjac glucomannan, put it into a 250 mL beaker, added distilled water to prepare 100 g of 1% glucomannan solution, and added to To this was added 200g of soybean oil and 30g of acrylate. Stir in a constant temperature water bath and control the temperature at 75 °C. Dissolve 12g of triethylamine, 5g of saponin, and 30g of absolute ethanol in 30mL of distilled water. The mixture was added to the above solution, emulsified and stirred for 120 min. Stir at room temperature for 4 h, then filter with suction, and wash repeatedly with distilled water until the filtrate is neutral, then collect the product. Get the konjac glucomannan of above-mentioned 200g modification and place in the beaker of 500 mL, take by weighing 108g 8-hydroxyquinoline copper and add in the beaker. Stir vigorously at room temperature for 3 h, filter with suction, and wash repeatedly with disti...

Embodiment 2

[0031]Fresh konjac was dried and crushed, sieved, purified with methanol or ethanol, and then dried; weighed 2.0 g of purified konjac glucomannan, put it into a 250 mL beaker, and added distilled water to prepare a 3% glucomannan solution. 300 g of soybean oil and 30 g of acrylate were added thereto. Stir in a constant temperature water bath and control the temperature at 85°C. Dissolve 10g of sodium hydroxide, 10g of polyacrylamide, and 50g of absolute ethanol in 50mL of distilled water. The mixture was added to the above solution, emulsified and stirred for 120 min. Stir at room temperature for 4 h, then filter with suction, and wash repeatedly with distilled water until the filtrate is neutral, and collect the product modified konjac glucomannan. Take 200 g of the above-mentioned modified konjac glucomannan and place it in a 500 mL beaker, weigh 205 g of copper aminophenylporphyrin and add it to the beaker. Stir vigorously at room temperature for 3 h, filter with suction...

Embodiment 3

[0037] Fresh konjac was dried and crushed, sieved, purified with methanol or ethanol, and then dried; weighed 2.5 g of purified konjac glucomannan, added it to a 250 mL beaker, and added distilled water to prepare a 2.2% glucomannan solution. To this was added 250g soybean oil and 45g acrylate. Stir in a constant temperature water bath and control the temperature at 85°C. Dissolve 20g of sodium hydroxide, 65g of soybean lecithin, and 50g of absolute ethanol in 50mL of distilled water. The mixture was added to the above solution, emulsified and stirred for 150 min. Stir at room temperature for 5 h, then filter with suction, and wash repeatedly with distilled water until the filtrate is neutral, and collect the product modified konjac glucomannan. An appropriate amount of modified konjac glucomannan was placed in a 500 mL beaker, and 170 g of copper dihydroxysuccinate was weighed and added to the beaker. Stir vigorously at room temperature for 3 h, filter with suction, and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com