Plant liquid for absorbing organic waste gas and machine for treating organic waste gas through combination process

A technology of organic waste gas and plant liquid, applied in the direction of gas treatment, use of liquid separation agent, separation method, etc., can solve the problems of reduced treatment efficiency, inapplicability, and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

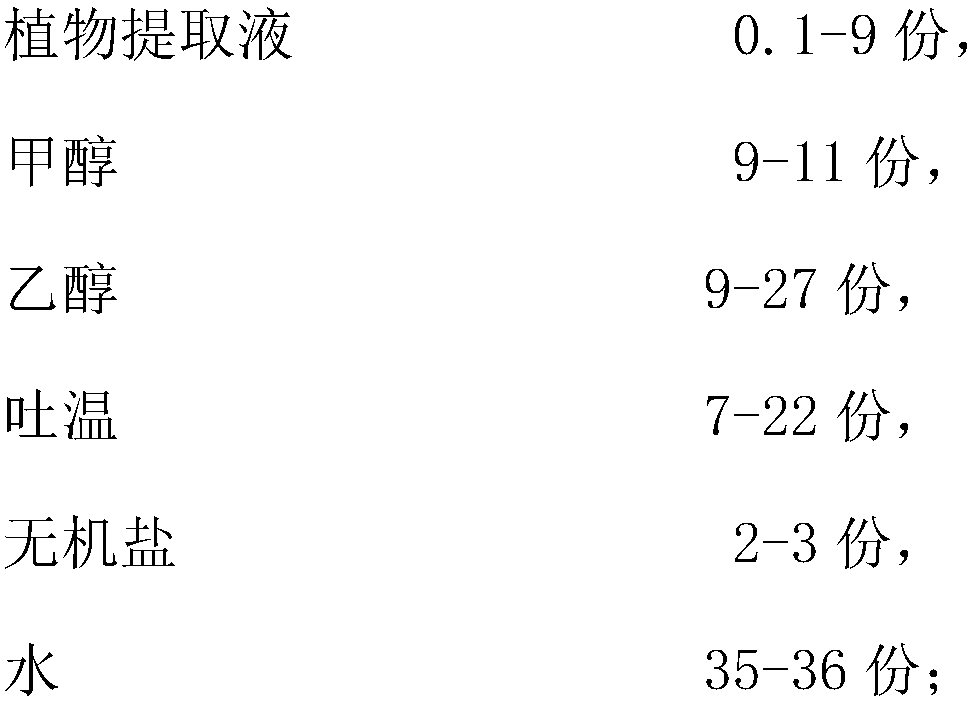

[0045] Using a 300L medicine tank, calculate the medicine consumption:

[0046] Natural plant absorption liquid, use 0.9Kg for 300Kg water. The main function of the plant liquid is to absorb organic waste gas through the principle of similar compatibility;

[0047] Surfactant Tween 20: 63Kg for 300Kg water;

[0048] Methanol, 90Kg for 300Kg water;

[0049] Ethanol, 300Kg water use 81Kg;

[0050] Surfactant in natural vegetable liquid: in Tween20 (21%) solution, the massfraction of toluene can reach 80.80%, promptly every 1KgTween20 (21%)-toluene-water microemulsion system can absorb 808g (8.78mol) toluene , The dosage of Tween 20 is 210g.

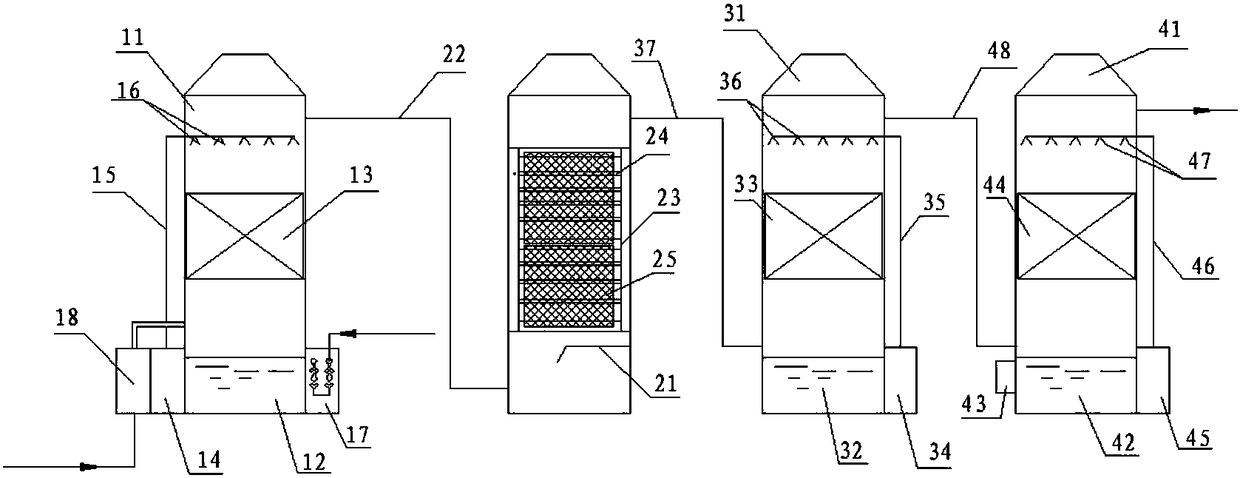

[0051] Such as figure 1 As shown, the embodiment of the present invention provides a machine for treating organic waste gas using the combined method of the above-mentioned plant liquid, including an active oxygen micro-nano bubble spray catalytic reactor, an ozone-free UV-anatase catalyzed photolysis reaction, a natural plant Liquid ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap