Light-duty beam splitter with grid rib structure and manufacturing method of beam splitter

A manufacturing method and beam splitter technology, which is applied in the direction of spectrometry/spectrophotometry/monochromator, instrument, scientific instrument, etc., can solve the problem that the volume and weight of the beam splitter cannot meet the miniaturization of the instrument Requirements and other issues, to achieve the effect of simplifying the structure of the instrument, using a wide range of materials, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

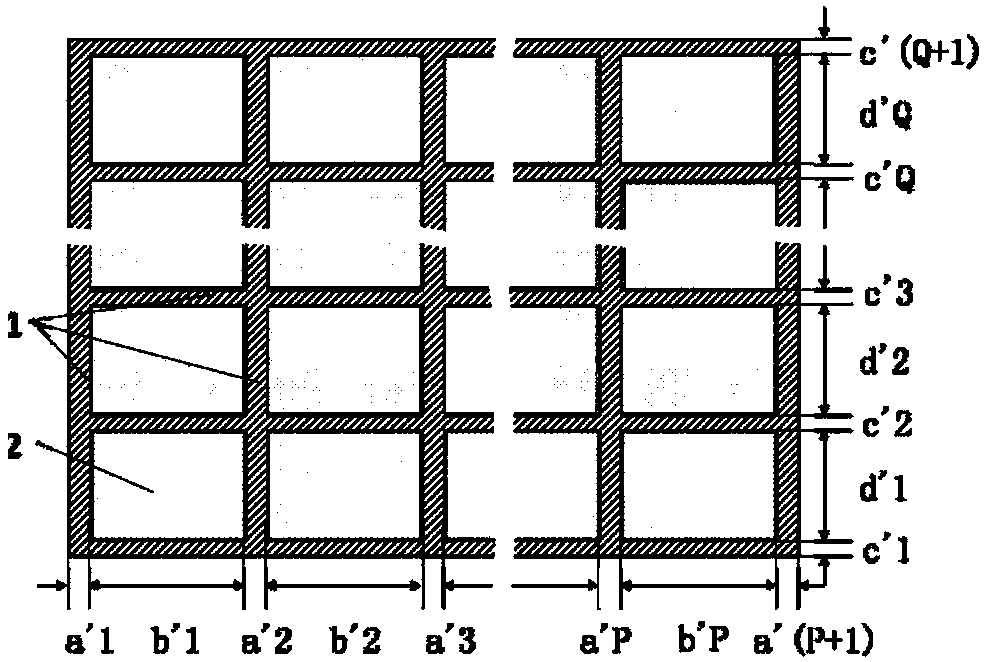

[0037] Specific implementation mode 1. Combination Figure 1 to Figure 8To illustrate this embodiment, the light-duty beam splitter with a grid structure includes a grid beam splitter and a grid beam splitter. Composed of a beam splitter and a beam splitter, the grating rib 1 spatially divides the beam splitter to form an array of beam splitter windows 2, the beam splitter film is located on the upper surface of the beam splitter window 2 or the upper surface of the beam splitter window 2 and the grating rib 1, for The incident beam is divided into two beams of refraction and reflection according to the required ratio. The grid ribs 1 support the beam-splitting film to ensure that the beam-splitting window structure has a good surface shape. The horizontal width of the grid ribs in the grid beam splitter is 2 times or other multiples of its longitudinal width, and the lateral width of the beam splitting window is 2 times of its longitudinal width, or other multiples. The ver...

specific Embodiment approach 2

[0053] Specific embodiment two, combine Figure 6 to Figure 8 This embodiment is described. This embodiment is the manufacturing method of the lightweight beam splitter with grid structure described in Embodiment 1. The manufacturing method can use ultra-precision machining methods and MOEMS technology to realize the grid beam splitter and Preparation of grid beam splitter;

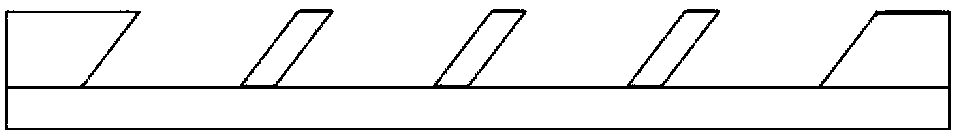

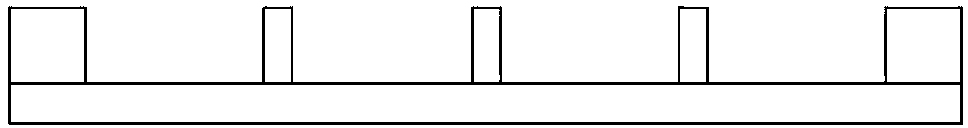

[0054] combine Image 6 To describe this embodiment, Image 6 For the process of making the grid beam splitter; firstly, the grid structure is made. The grid structure is made by Micro-Opto-Electro-Mechanical System (MOEMS) process, specifically combined with Image 6 As shown, select undoped semiconductor materials such as silicon (Si), germanium (Ge) and gallium arsenide (GaAs) as the substrate, and first spin coat a layer of photoresist on the semiconductor substrate material, such as Image 6 a, then expose and develop with a grid pattern mask to remove the photoresist at the position of the beam ...

Embodiment 1

[0062] Embodiment 1, with above-mentioned figure 2 The grid beam splitter shown in s is manufactured, and the material is a double-sided polished (100) single crystal silicon wafer with high flatness and high parallelism. Its preparation method is:

[0063] 1. Growth or evaporation of silicon dioxide and silicon nitride and other dielectric films or composite films on the cleaned double-sided polished single crystal silicon surface as a masking film;

[0064] 2. Directional photolithography to expose the side groove pattern, and remove the masking film in the side groove pattern by etching to expose the surface of the single crystal silicon. Use single crystal silicon anisotropic etching solution to etch the side groove, and the etching depth is equal to the final thickness of the beam splitter window; the shape of the side groove can also be formed by arranging multiple rectangles or squares at a certain distance apart from the figure shown in the figure.

[0065] 3. Perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com