Method for preparing bismuth-base oxide nanosheet and application of bismuth-base oxide nanosheet

A technology of nanosheets and oxides, applied in the field of materials, can solve the problems of inability to fundamentally degrade formaldehyde, long formaldehyde release cycle, and inability to degrade formaldehyde, and achieve easy control of process parameters, high catalytic decomposition ability, high surface potential and The effect of electrostatic potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Weigh 2.4g bismuth nitrate and mix with 60ml deionized water, stir for 10 minutes, add 2.6g copper nitrate powder, stir for 10 minutes until the solution turns blue; add 1.6g NaOH to the blue solution and stir until flocculation, then continue stirring for 10 minutes ; Add 1 g of thiourea and 0.16 g of CTAB to the flocculent mixture, and stir for 10 minutes to obtain a brown solution; put the solution into a hydrothermal kettle, heat it to 160 ° C, keep it warm for 12 hours, and repeatedly wash and dry it three times to obtain BiCuSO Nanosheets.

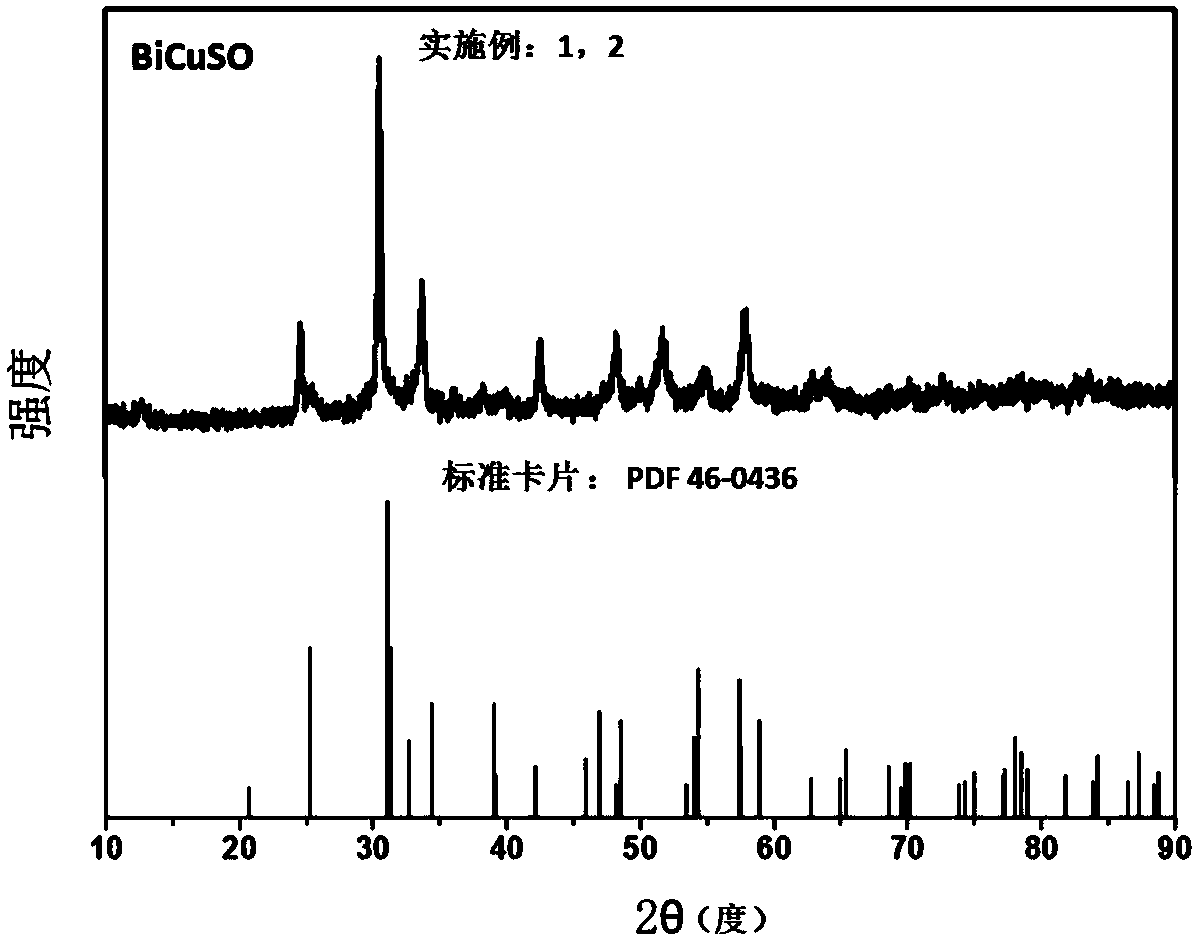

[0077] in, figure 1 and figure 2 The SEM and TEM images of the prepared BiCuSO nanosheets are respectively, and the XRD images of the BiCuSO nanosheets are shown in image 3 shown, from figure 1 and figure 2 It can be seen that the prepared BiCuSO has a nanosheet structure.

Embodiment 2

[0079] Weigh 2.46g bismuth oxide and mix with 60ml deionized water, stir for 10 minutes, add 2.6g copper nitrate powder, stir for 10 minutes until the solution turns blue; add 1.6g NaOH to the blue solution and stir until flocculation, then continue stirring for 10 minutes ; Add 1 g of thiourea and 0.16 g of CTAB to the flocculent mixture, and stir for 10 minutes to obtain a brown solution; put the solution into a hydrothermal kettle, heat it to 160 ° C, keep it warm for 12 hours, and repeatedly wash and dry it three times to obtain BiCuSO Nanosheets. Among them, the XRD pattern of BiCuSO nanosheets is as follows image 3 shown.

Embodiment 3

[0081] The BiCuSO / Au composite was prepared by using the BiCuSO nanosheets prepared in Example 1.

[0082] Mix 0.2g of BiCuSO nanosheets with 0.05g of gold tetrachloride powder and stir for 10 minutes, add 50Ml deionized water to the mixture, continue stirring for 10 minutes, then add NaOH to adjust the pH value to 9, and place the mixed solution on Irradiated and stirred under the visible light of a xenon lamp for 12 hours; the obtained solution was centrifuged, washed and dried three times repeatedly, and the BiCuSO / Au composite was obtained.

[0083] in, Figure 4 The formaldehyde catalytic degradation performance diagram of the prepared BiCuSO / Au composite under visible light irradiation, from Figure 4 It can be seen that the BiCuSO / Au composite can effectively catalyze the degradation of formaldehyde under visible light irradiation, and the catalytic degradation of formaldehyde degradation can reach more than 75% under visible light irradiation for 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com