Wing type sludge pipe pyrolysis reactor

A pyrolysis reactor and the technology of the reactor, which are used in the pyrolysis treatment of sludge, special forms of dry distillation, petroleum industry, etc., can solve the problems of increasing the difficulty of tar upgrading treatment, tar sticking or blocking, deflagration, etc. Enhanced heat transfer and pyrolysis effect, increased update frequency, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

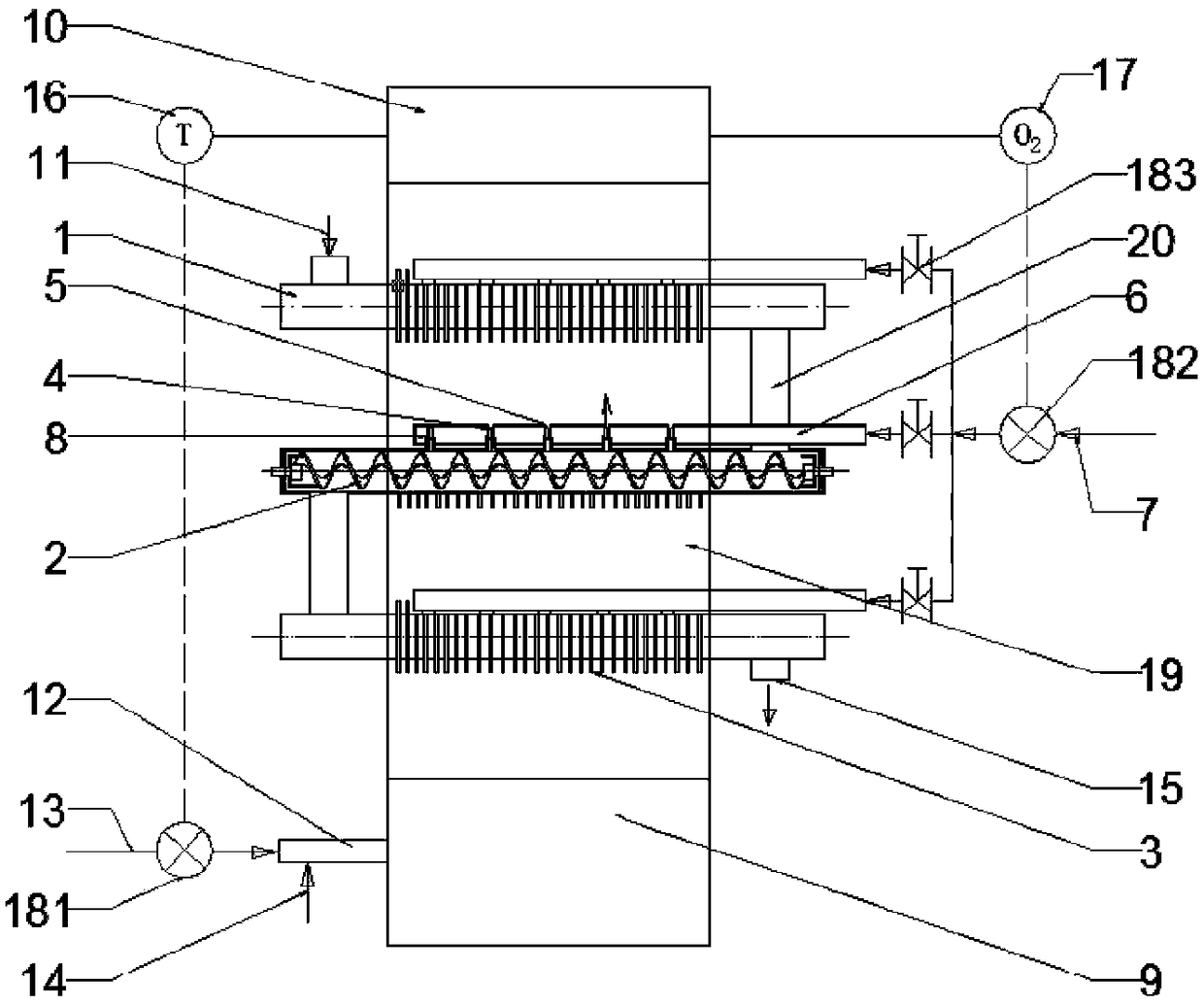

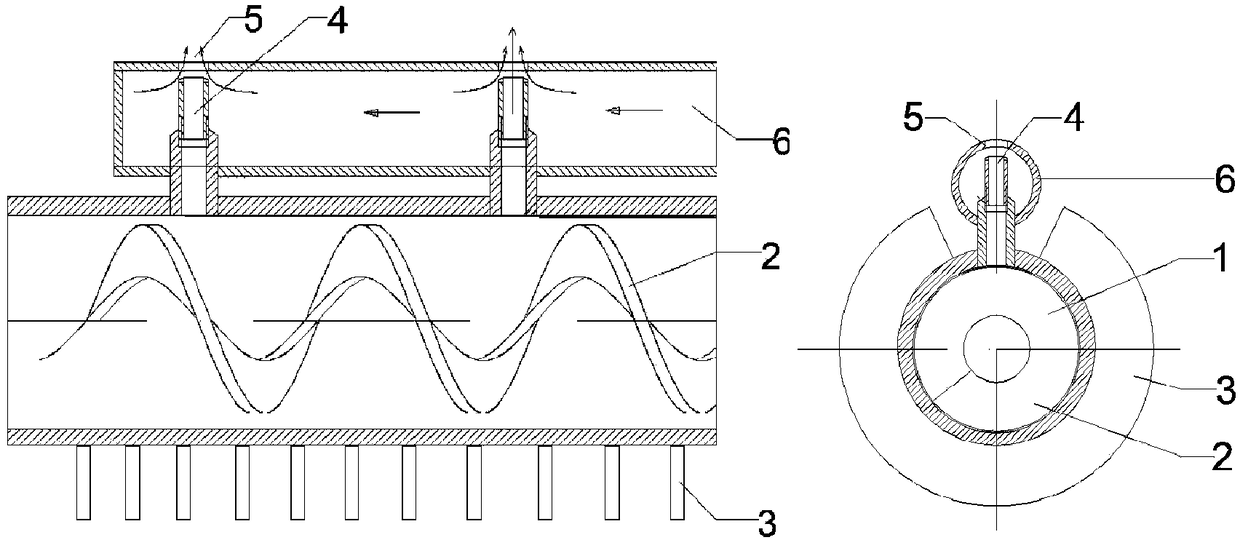

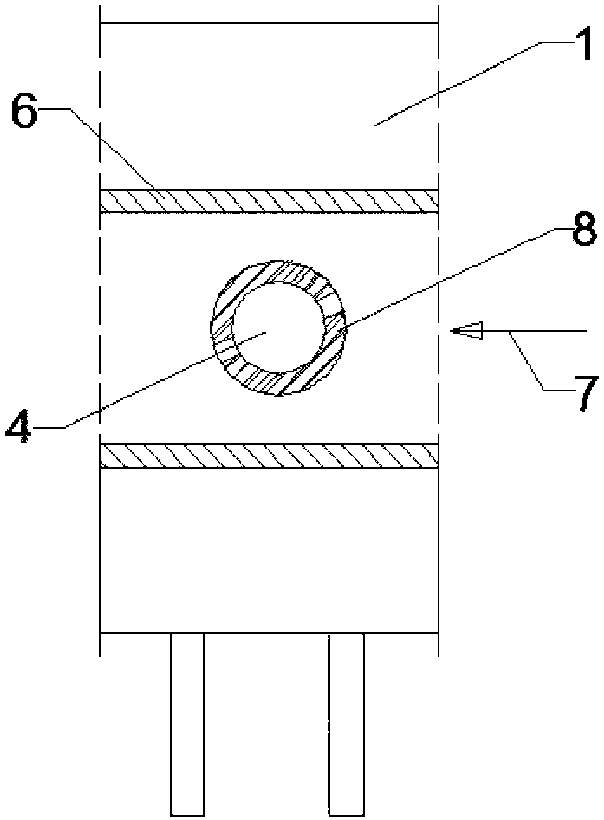

[0028]A wing-type sludge tube pyrolysis reactor, the reactor is composed of a pyrolysis furnace 19, a combustion chamber 9, and a flue gas mixing chamber 10, the bottom of the pyrolysis furnace 19 is connected to the combustion chamber 9, and the top of the pyrolysis furnace 21 is Connected with the flue gas mixing chamber 10, the combustion chamber 9 is equipped with a natural gas burner 12, the amount of natural gas is regulated by the temperature measuring and control instrument 16 installed on the flue gas mixing chamber 10, and the pyrolysis furnace 19 is equipped with at least 2 layers of pyrolysis Tube 1, both ends of each pyrolysis tube 1 extend out of the pyrolysis furnace 19 and are respectively provided with a mud inlet port and a mud outlet port, and the mud inlet port of the uppermost pyrolysis pipe is used as the mud inlet port of the reactor 11. The mud outlet port of the bottom pyrolysis tube 1 is used as the biochar outlet 15 of the reactor, and the mud outlet ...

Embodiment 2

[0031] A wing-type sludge tube pyrolysis reactor, consisting of a pyrolysis furnace 19, a combustion chamber 9, and a flue gas mixing chamber 10, the bottom of the pyrolysis furnace 19 is connected to the combustion chamber 9, and the top of the pyrolysis furnace 21 is connected to the flue gas The mixing chambers 10 are connected, the combustion chamber 9 is provided with a natural gas burner 12, the amount of natural gas is regulated by a temperature measuring and control instrument 16 arranged on the flue gas mixing chamber 10, and the pyrolysis furnace 19 is provided with a multilayer pyrolysis tube 1, each Both ends of each pyrolysis tube 1 extend out of the pyrolysis furnace 19. Outside the pyrolysis furnace 19, a mud inlet 11 is provided above one end of the uppermost layer of pyrolysis tube 1, and the bottom of the other end is connected to the upper and lower floor pyrolysis tubes. 20 is connected with the top of one end of the lower pyrolysis tube 1, and so on, the ot...

Embodiment 3

[0035] A new type of wing-type sludge tube pyrolysis reactor for municipal sludge disposal. The flue gas mixing chamber 10 is equipped with a heat transfer oil or steam heat exchanger and an air preheater. The flue gas is discharged after treatment. The heat of the heat conduction oil or steam heat exchanger is used to dry the wet sludge with 80% water content, so that the sludge moisture content in the sludge inlet 11 is below 20%, and the heat of the air preheater is used to heat the combustion air 14 and enter the hot air Inlet 7 air. The combustion chamber 9 is equipped with a diesel or heavy oil burner to ensure that the temperature of the flue gas mixing chamber 10 is 850°C, the temperature of the hot air inlet is 200°C, the oxygen content of the flue gas mixing chamber 10 is controlled at about 6%, and the fin ratio is 1.5 When compared with the light tube, the pyrolysis treatment capacity is about 15% higher.

[0036] Working process of the present invention is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com