Method for comprehensive recovery of multiple metal of nickel, iron and magnesium in silicon-magnesium type laterite nickel ore

A laterite-nickel ore and polymetallic technology, which is applied in the comprehensive recovery of magnesium and polymetallics, and the field of nickel in iron and silicon-magnesium-type laterite-nickel ore, can solve the problem of unsatisfactory economic benefits and unreasonable utilization of low-grade silicon-magnesium-type laterite-nickel ore resources. and other problems, to achieve the effect of comprehensive utilization of short process, low cost and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

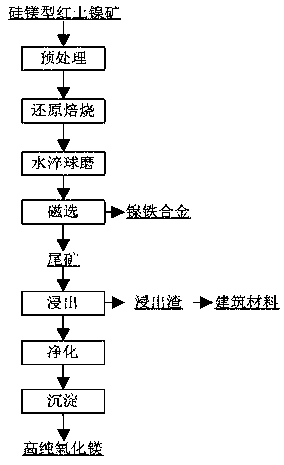

[0028] Such as figure 1 Shown, the method for comprehensive recovery of nickel, iron, magnesium polymetallic in this silicon-magnesium type laterite nickel ore, its specific steps are as follows:

[0029] Step 1. First, silicon magnesium type laterite nickel ore (silicon magnesium type laterite nickel ore includes the following mass percentage components: Ni0.82%, Fe9.7%, MgO31.5%, SiO 2 37.4%) were dried, crushed to a particle size of 3-4µm, and sieved to obtain mineral powder;

[0030] Step 2, mix the ore powder obtained in step 1 with anthracite and accelerator to form pellets, and the pellets are reduced and roasted to obtain roasted ore; the mass ratio of ore powder to anthracite and accelerator is 1:0.1:0.12, and the pellets The diameter is 40mm, and the reduction roasting temperature is 1250°C for 2 hours; the accelerator is Na 2 SO 4 ;

[0031] Step 3. After the roasted ore obtained in step 2 is subjected to water quenching ball milling, the pulp after ball milling...

Embodiment 2

[0036] Such as figure 1 Shown, the method for comprehensive recovery of nickel, iron, magnesium polymetallic in this silicon-magnesium type laterite nickel ore, its specific steps are as follows:

[0037] Step 1, first the silicon magnesium type laterite nickel ore (silicon magnesium type laterite nickel ore includes the following mass percentage components: Ni1.5%, Fe8%, MgO40%, SiO 2 35%), dried, crushed to a particle size of 2-3µm, and sieved to obtain mineral powder;

[0038] Step 2, mix the ore powder obtained in step 1 with anthracite and accelerator to form pellets, and the pellets are reduced and roasted to obtain roasted ore; the mass ratio of ore powder to anthracite and accelerator is 1:0.12:0.10, and the pellets The diameter is 30mm, and the reduction roasting temperature is 1150°C for 2.5h; the accelerator is NaCl;

[0039] Step 3. After the roasted ore obtained in step 2 is subjected to water-quenching ball milling, the pulp after ball milling is subjected to m...

Embodiment 3

[0044] Such as figure 1 Shown, the method for comprehensive recovery of nickel, iron, magnesium polymetallic in this silicon-magnesium type laterite nickel ore, its specific steps are as follows:

[0045] Step 1, first the silicon magnesium type laterite nickel ore (silicon magnesium type laterite nickel ore includes the following mass percentage components: Ni1.2%, Fe15%, MgO30%, SiO 2 45%) are dried, crushed to a particle size of 1-2µm, and sieved to obtain mineral powder;

[0046] Step 2, mix the ore powder obtained in step 1 with anthracite and accelerator to form pellets, and the pellets are reduced and roasted to obtain roasted ore; the mass ratio of ore powder to anthracite and accelerator is 1:0.08:0.08, and the pellets The diameter is 50mm, and the reduction roasting temperature is 1250 ° C for 3 hours; the accelerator is CaCl 2 ;

[0047] Step 3. After the roasted ore obtained in step 2 is subjected to water quenching ball milling, the pulp after ball milling is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com