Magnetic nano-sphere grafted with arginine polymer brush, and preparation method and application thereof

A technology of magnetic nanospheres and polymer brushes, which is applied in the preparation methods of peptides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of high anaerobic requirements, unfavorable popularization and application, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 5

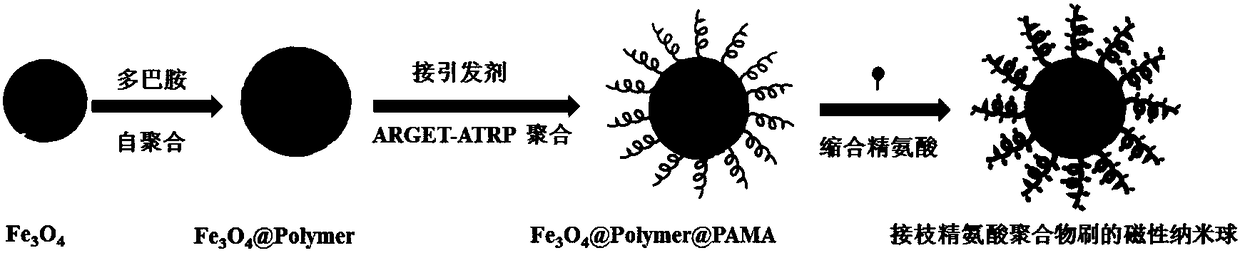

[0047] Embodiment 1-embodiment 5 prepares Fe 3 o 4 / Polymer nanosphere

[0048] Take the raw material according to table 1, and prepare Fe according to the following method in conjunction with the process parameters given in table 1 3 o 4 / Polymer nanospheres: Add Fe to Tris buffer containing dopamine at pH 8.2 to 8.5 3 o 4Magnetic balls, and then stirred and reacted for 2h to 12h under the condition of the opening of the reaction vessel to obtain the first reaction solution, magnetically separated the first reaction solution and collected the separated solid product, and then washed the solid product with deionized water to remove untreated Coated in Fe 3 o 4 The polydopamine layer on the surface of the magnetic ball and the unreacted dopamine raw materials are obtained by the polydopamine layer-coated Fe 3 o 4 Magnetic ball, namely Fe 3 o 4 / Polymer nanosphere; pH 8.2-8.5 buffer solution containing dopamine is formed by dissolving dopamine in Tris buffer solution, ...

Embodiment 6- Embodiment 9

[0052] Embodiment 6-embodiment 9 prepares Fe 3 o 4 / Polymer-Br nanospheres

[0053] Take the raw material according to table 2, and prepare Fe according to the following method in conjunction with the process parameters given in table 2 3 o 4 / Polymer-Br nanosphere: the Fe that embodiment 3 obtains 3 o 4 / Polymer nanospheres are uniformly dispersed in DMF to obtain Fe 3 o 4 / Polymer nanosphere suspension; first vacuumize the reaction container of the two-necked flask with a stirrer for 5 minutes to 10 minutes, then pass nitrogen to normal pressure, and repeat this operation three times to ensure that the oxygen in the reaction container is completely removed. state; then add Fe 3 o 4 / Polymer nanosphere suspension, in the state of magnetic stirring, to Fe 3 o 4 Add 0.5mL-2mL triethylamine dropwise to the / Polymer nanosphere suspension to obtain the first mixed solution, then add 0.4mL-1.8mL 2-bromoisobutyryl bromide dropwise to the first mixed solution under ice-bath...

Embodiment 10- Embodiment 13

[0056] Embodiment 10-embodiment 13 prepares Fe 3 o 4 / Polymer / PAMA nanospheres

[0057] Take the raw material according to table 3, and prepare Fe according to the following method in conjunction with the process parameters given in table 3 3 o 4 / Polymer / PAMA nanospheres: the Fe prepared in Example 9 3 o 4 / Polymer-Br nanospheres are uniformly dispersed in DMF to obtain Fe 3 o 4 / Polymer-Br nanosphere suspension; first vacuumize the reaction container of the two-necked flask with a stirrer for 5 minutes to 10 minutes, then pass nitrogen to normal pressure, and repeat this operation three times to ensure that the oxygen in the reaction container is completely removed; under nitrogen environment , add Fe to the reaction vessel 3 o 4 / Polymer nanosphere suspension, in the state of magnetic stirring, to Fe 3 o 4 Add the DMF solution of the catalyst and the complex and the DMF solution of the monomer AMA to the Polymer-Br nanosphere suspension in turn to obtain the secon...

PUM

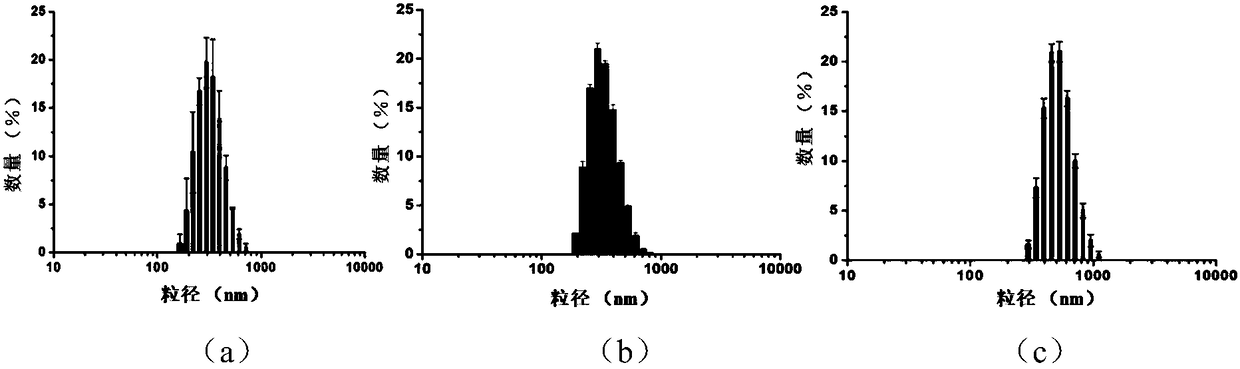

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com