Triamcinolone acetonide acetate and miconazole nitrate neomycin sulfate cream and preparation method thereof

The technology of Quimixin and cream, applied in the field of Quimixin cream and its preparation, can solve the problems of uneven distribution of main drug components, easy instability of the cream, loss of effectiveness of the cream, etc. Improved penetration and reduced stinging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of above-mentioned trimides new emulsifiable cream, it comprises:

[0037] S1. Mix the water-based auxiliary material with the first water at 75-85°C and keep it warm for 25-45min to obtain the water phase. Make each substance in the water-based auxiliary material fully mixed with the first water.

[0038] It is preferably mixed in a water phase tank, and the operation is simple and convenient.

[0039] Preferably, the water-based auxiliary material is mixed with 120-125 parts by weight of water at 130-170 r / min for 2.5-3.5 hours; further, each substance in the water-based auxiliary material is fully mixed with the first water.

[0040] S2. Mix the oil-based auxiliary materials at 75-85°C and keep warm for 25-45min to obtain the oil phase. Make the various substances in the oil-based excipients fully mixed.

[0041] Specifically, add the oil-based auxiliary material into the oil phase tank and heat to p...

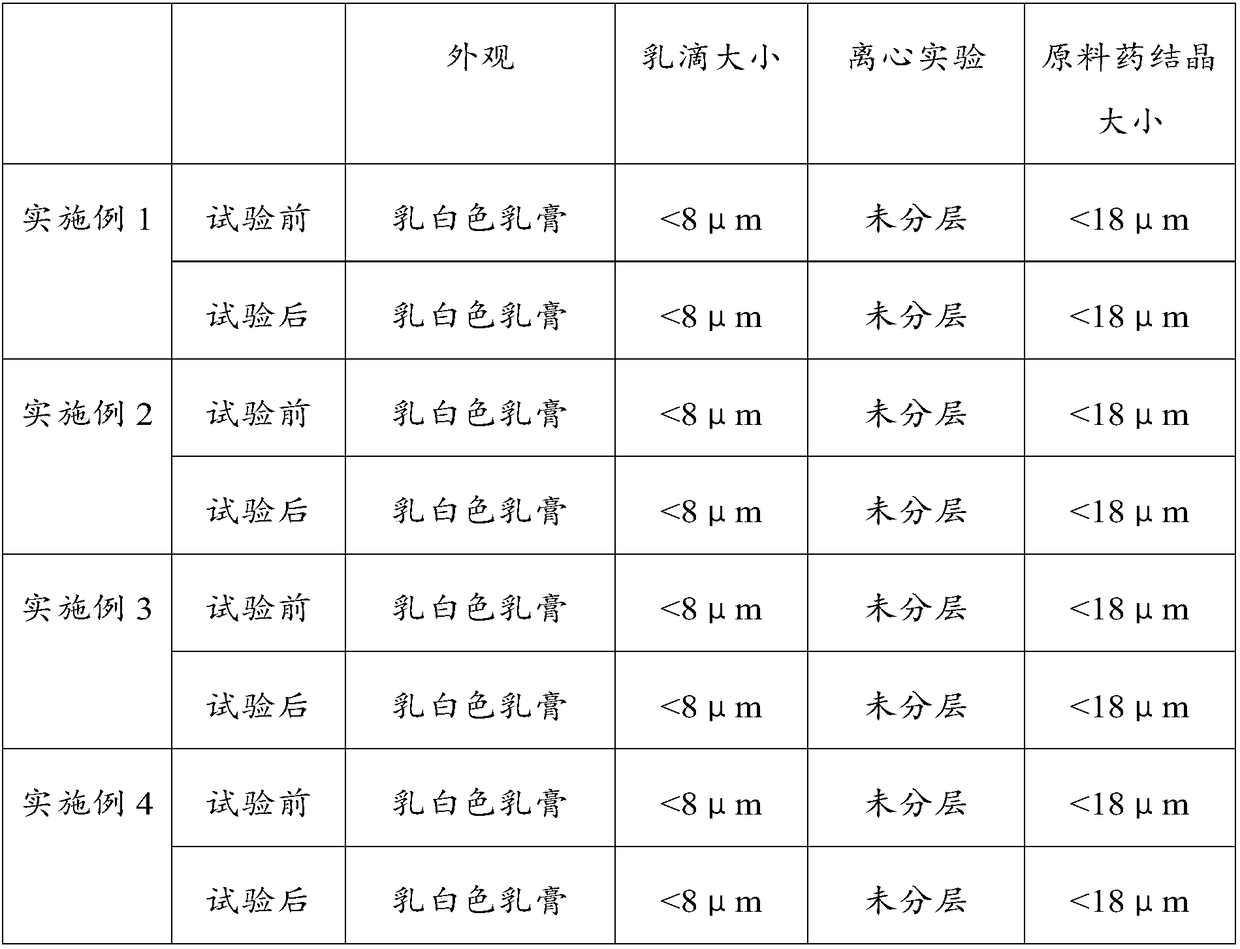

Embodiment 1

[0053] A new emulsifiable paste, which is made by the following method:

[0054] S1. Mix the water-based auxiliary material with the first water, raise the temperature to 85°C, mix for 2.5 hours under the condition of 160r / min, and keep it warm for 45 minutes to obtain the water phase.

[0055] Among them, the water-based excipients include polysorbate, sorbic acid, propylene glycol, pingpingjia, and a mixture of glyceryl stearate and polyethylene glycol stearate in a weight ratio of 5:0.6:19:2:3.

[0056] S2. Add the oil-based auxiliary materials into the oil phase tank, heat, and after part of the oil-based auxiliary materials melt, start the stirring device and mix for 2.5 hours under the conditions of 85°C and 155r / min, and keep warm for 40 minutes to obtain the oil phase.

[0057] The oil-based excipients include liquid paraffin, stearic acid, sorbitan monostearate, cetyl alcohol, stearyl alcohol and isopropyl palmitate in a weight ratio of 5:3:3:6:7:7.

[0058] S3. Firs...

Embodiment 2

[0063] A new emulsifiable paste, which is made by the following method:

[0064] S1. Mix the water-based auxiliary material with the first water, raise the temperature to 75°C, mix for 3.5 hours under the condition of 150r / min, keep it warm for 30 minutes, and obtain the water phase.

[0065] Among them, the water-based excipients include polysorbate, sorbic acid, propylene glycol, pingpingjia, glyceryl stearate and polyethylene glycol stearate with a weight ratio of 6:0.7:19:2.5:2:0.5:0.015. mixture, sodium hydroxide and disodium edetate.

[0066] S2. Add the oil-based auxiliary materials into the oil phase tank, heat, and after part of the oil-based auxiliary materials melt, start the stirring device and mix at 80°C and 155r / min for 3 hours, then keep warm for 35 minutes to obtain the oil phase.

[0067] The oil-based excipients include liquid paraffin, stearic acid, sorbitan monostearate, cetyl alcohol, stearyl alcohol and isopropyl palmitate in a weight ratio of 4:2.5:4:6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com